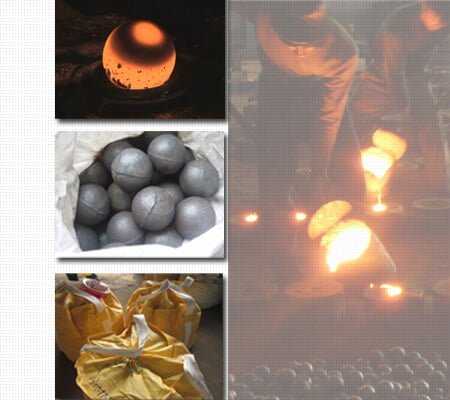

The Most Widely Used Grinding Medium

——Steel Ball

Steel ball, as the indispensable consumable to ball mill, is a kind of wear-resistant material that made of carbon, chromium, manganese, and molybdenum, etc. as the main added metal elements, and can be produced through forging, spinning, rolling, grinding and casting.

Grinding Cost Analysis

Based on a relevant data analysis, steel ball has great influence on cost and performance of grinding, and takes 8 % on the mill plant overall operating costs, and 30% on the whole grinding cost, thus steel ball affects a lot to the total grinding operation, efficiency and operating cost. Choosing the proper steel ball to reduce the loss is an important way to improve the efficiency of mill plant.

- 50%: Grinding Equipment

- 30%: Energy Consumption

- 10%: Grinding Medium

- 10%: Personnel and Others

Dangers to Use Inferior Steel Ball

Inferior steel ball can easily crack and spalling, which can shorten the service life of the slurry pump, hydrocyclone, and the cycle load line. Steel Ball Scraps distribute to increase the ball mill load and the energy consumption.

What is Quality-Assured Steel Ball

Forged Steel Ball

Applied advanced forging technology and solution of constant temperature pouring Promise the forged steel ball of RCAB, which chemical element is reasonable layout and less impurities, the forged steel ball also can ensure optimal hardening properties High toughness, the core hardness can reach 55-64HRC, and surface hardness of 55-65 HRC. Applications Semi-autogenous mill, ball mill, vertical mill processing solution of gold, copper, iron and other metal.

Casting Steel Ball

Applied the swage quench process which can ensure 7.6g/mm2 of specific gravity, 10%-14% of chromium-contained Rockwell hardness of HRC58-63 and the falling experiments above 8.5 meters are more than 20000. Promise the casting steel ball without deforation, high abrasion and high shatter-resistant with uniform hardness. Applications Ball mill,vertical mill, and process solution of iron ore, coal ore, cement and other industry ore, etc. which is mainly used to deal with fine powder grinding and dry grinding process