Nigeria 100TPH Coltan Process Plant

Raw Material: <150mm Coltan(columbite-tantalum)

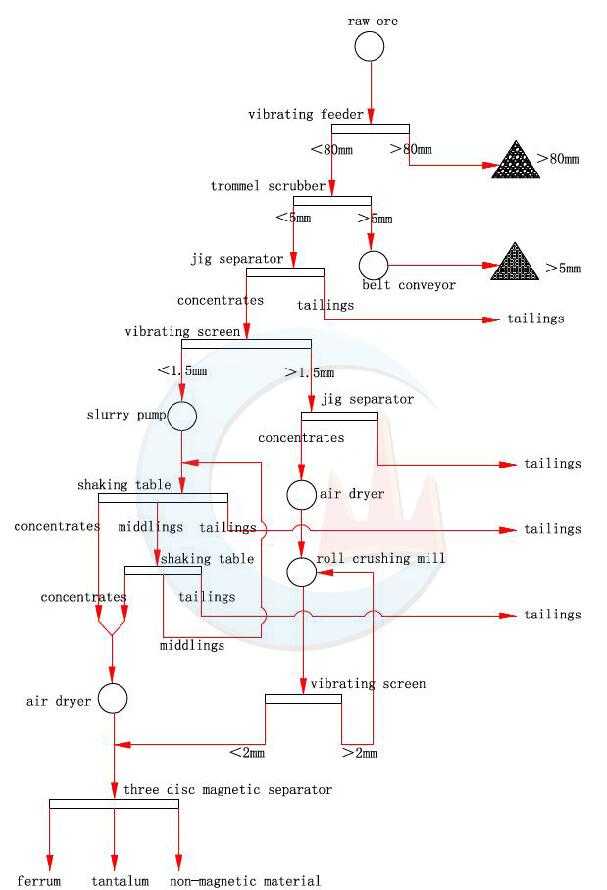

Main Equipment: drum trommel scrubber with screen, jig separator, vibrating screen, shaking table, roll crushing mill, air dryer, three disc magnetic separator, etc.

Project Introduction

Raw ore size <200mm, high mud content and strong clay viscosity. The client want get ferrum, tantalum and non-magnetic material.

If we want to get columbite-tantalum concentrates, first, we must wash and desliming the ore and remove the disturbance of soil. Ores washing machines are widely used drum trommel scrubber, log washer to washing tantalum in in Africa. The solution we have designed for our client is to use a drum trommel scrubber with a screening function. Then it goes into the beneficiation process.The details as follow:

Process Description

Washing Process: the <80mm materials feed into trommel scrubber to washing and screening. <5mm materals go to beneficiation flowsheet, others transport away.

Extract tantalum from coltan ores: use gravity separation equipment jig machine to separat concentrates and tailings. The concentrates are screened two size by vibrating screen. <1.5mm concentrates feed into shaking table, >1.5mm concerntrates are crushed again by roll crusher. We use other group shaker table for middlings tantalum. At Last, the three disc magnetic separator are used to separate ferrum, tantalum, and non-magnetic material.