Cone Crusher

Types: GP, HP, Symons crusher

Feeding: <500mm

Application: metallurgy, quarry, construction, building industry, etc

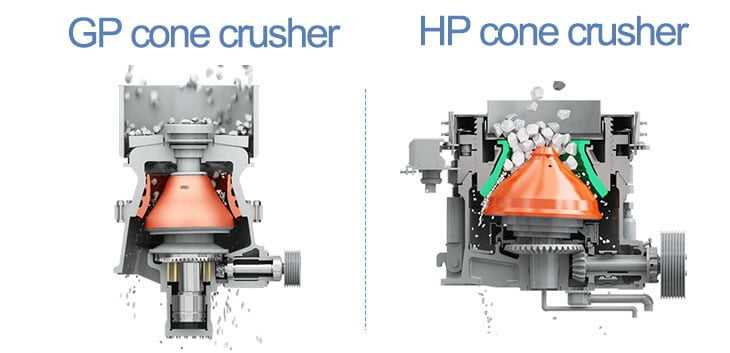

GP Cone Crusher

Feeding size:S cavity ≤500mm / Standard cavity ≤ 370mm

Capacity:S cavity 70-860 t/h / Standard cavity 25-2185 t/h

Application:Applicable to metallurgy, construction, hydropower, transportation, chemical industry, building materials industry and other fields

Material:Suitable for crushing all kinds of hard and above medium hardness materials, such as river pebbles, limestone, dolomite, granite, rhyolite, diabase.

Advantages:

Less consumption of wearing parts and low running cost. The hydraulic discharge orifice is used to adjust the ore outlet in a timely and convenient manner, so that the crusher can work under the state of being full of feed. Only by replacing the lining board can different crushing cavity types be obtained, which can meet different process requirements of coarse and fine crushing.

Download Technical Specifications PDF

HP Cone Crusher

Feeding size:≤ 335mm

Capacity:40-1220t/h

Application:suitable for crushing hard or medium hardness ore and rock

Material:river pebbles, limestone, daolomite, granite, rhyolite, diabase, etc

Advantages:

The hp hydraulic cone crusher adopts a fixed main shaft design, which combines the spindle speed, stroke and crushing cavity shape, thereby improving the production capacity and product quality, and improving the fine crushing ability. In the crushing process, the layered crushing makes the aggregate shape has been greatly improved.

Download Technical Specifications PDF

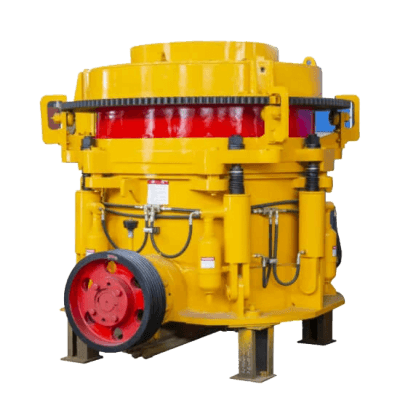

Symons Cone Crusher

Feeding size:B cavity 87-460mm / D cavity 37-170mm

Capacity:B cavity 46-1642t/h / D cavity 27-720t/h

Application:metallurgy, construction, hydropower, transportation, chemical industry, building materials and other industries.

Material:river pebbles, limestone, dolomite, granite, rhyolite, diabase.

Advantages:

The spring cone crusher has reasonable structure, excellent crushing principle and technical parameters, reliable operation, low operating cost, large crushing force, high production efficiency and high output.

Download Technical Specifications PDF

Need Engineer Help?

Overview

The supply of minerals, rocks and aggregates is essential for the sustainable development of today’s society. As a high performance rock crusher, most of cone crushers are adopted in the mineral processing plants, rock and aggregate processing plants. Cone crushers are used to reduce the particle size of rock materials or to liberate valuable minerals from ores, and are usually used as secondary crushers or tertiary crushers in crushing circuits.

Early crushers used springs to protect the tramp iron and adjust them manually. In addition to the hydraulic setting adjustment system, the newer crushers also use a safer and more reliable hydraulic tramp iron release and removal system. The hydraulic setting adjustment system can adjust the crusher settings as needed to optimize the crusher performance, allow remote setting changes, and connect to the automation system.

https://www.youtube.com/watch?v=AVRK4aCAjYU

models & specifications

Parameter Structure Features Application Parameter

1. GP Cone Crusher Technical Specifications PDF Download

2. HP Cone Crusher Technical Specifications PDF Download

3. Symons Cone Crusher Technical Specifications PDF Download

Structure

The main parts of the cone crusher are bowls, mantle, eccentric components, linings, etc. and the operational part of the cone crusher is the crushing chamber, which consists of concave and mantle. During the crushing operation, the mantle moves around the axis of the crushing chamber.

The triangular belt transmits the power from source to the shaft, which eccentrically rotates the mantle and compresses the rock between the mantle and the concave surface.

During crushing, the rock material enters the crushing chamber from the top feed inlet and falls continuously until it reaches the level of the choke.The rocky material is then pushed by the mantle onto the concave liner, squeezed and compressed into small pieces. When the mantle is away from the concave lining, the rock material spreads out and falls. After several cycles, the size of the rock material gradually decreases to meet the predetermined requirements and is discharged from the bottom discharge outlet.

An improved conical rock crusher will improve the crushing effect and increase the crushing efficiency, while providing a more functional and economical equipment. Users can adjust the crushing cavity, speed, throwing and lining of the rock crusher for various rock crushing specifications.

Features

1. Different types of cavity

operated in open circuit, can be fitted with fine, medium, coarse or extra coarse crushing cavities.

2. HP, GP, Compound Cone Crusher

Select the rightest cone crushers to maximize your profit. Optimized crushing with the lowest maintain.

3. Hydraulic control, safe and friendly

precise adjustment and control of discharging, rapid response self-protection when there is blockage.

Application