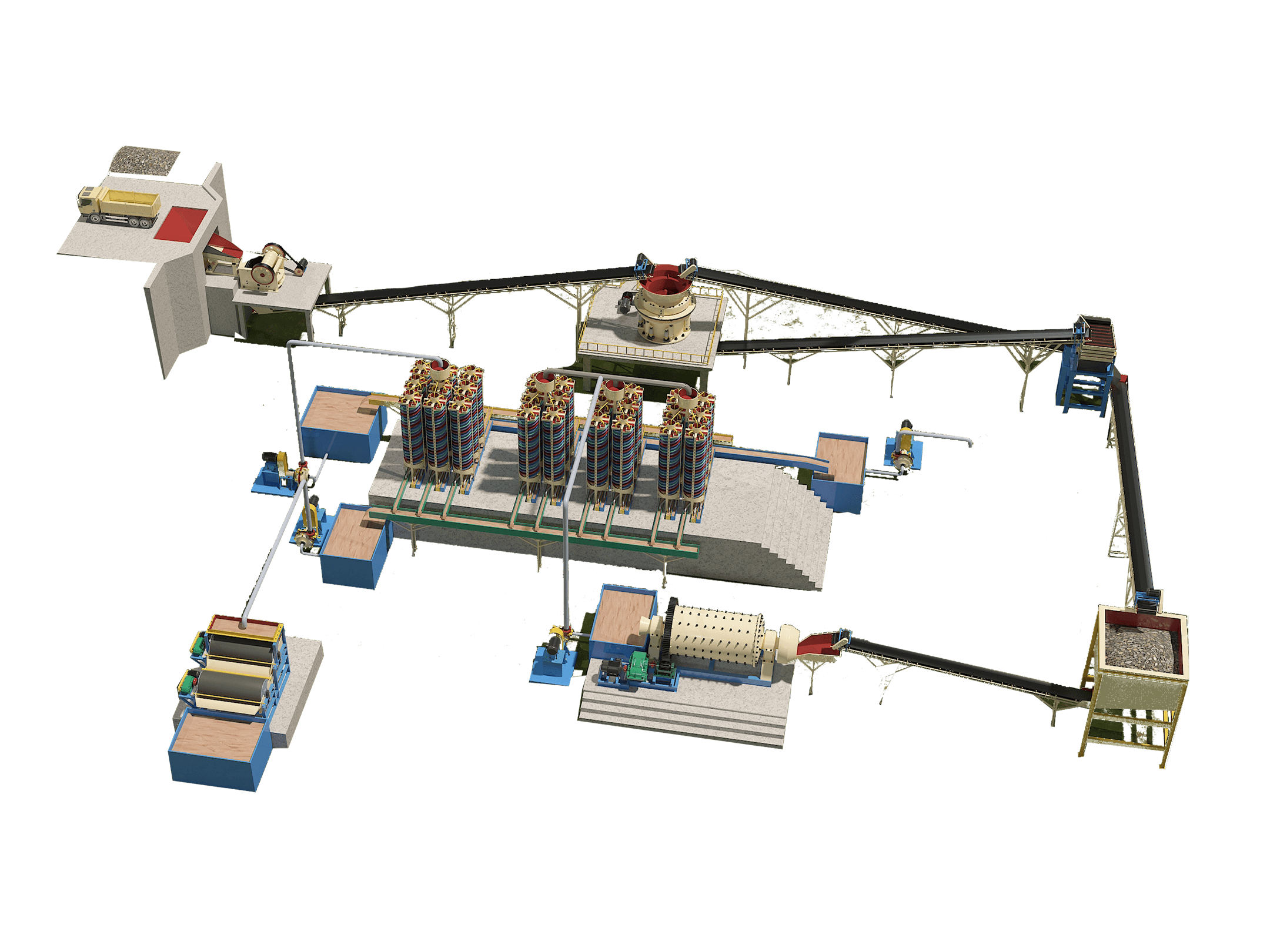

Dewatering & Tailing Management Equipment

In mineral processing flow, the concentrates and tailings produced by different of treating methods must be dewatered, so these pulps products can convert to a transportable state. In addition, the water can be recycled into the existing water circuits of the processing plant, greatly reducing the demand for expensive freshwater.

Hot Sale EquipmentTop choice equipment for crushing or grinding stage processing

Rock CrusherJaw Crusher

Grinding MillsBall Mill

Grinding MillsWet Pan Mill

Aggregate, Comminution, and Grinding Equipment

Talk with JXSC’s mining experts to get more help, fell free to conslution!

Dewatering equipment for mineral precessing

In mineral processing flow, the concentrates and tailings produced by different of treating methods must be dewatered, so these pulps products can convert to a transportable state. In addition, the water can be recycled into the existing water circuits of the processing plant, greatly reducing the demand for expensive freshwater.

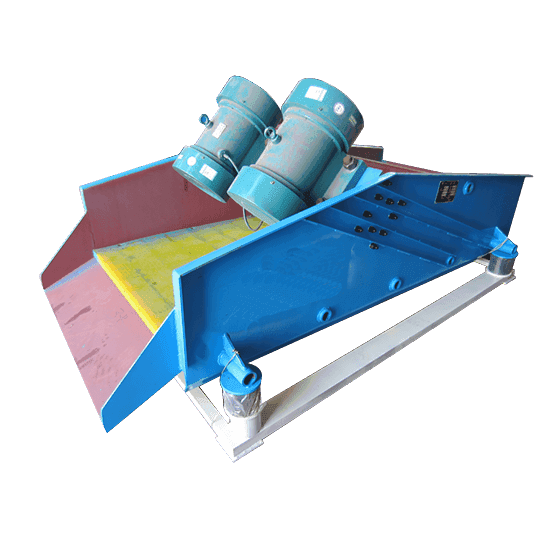

dewatering screen

filter press

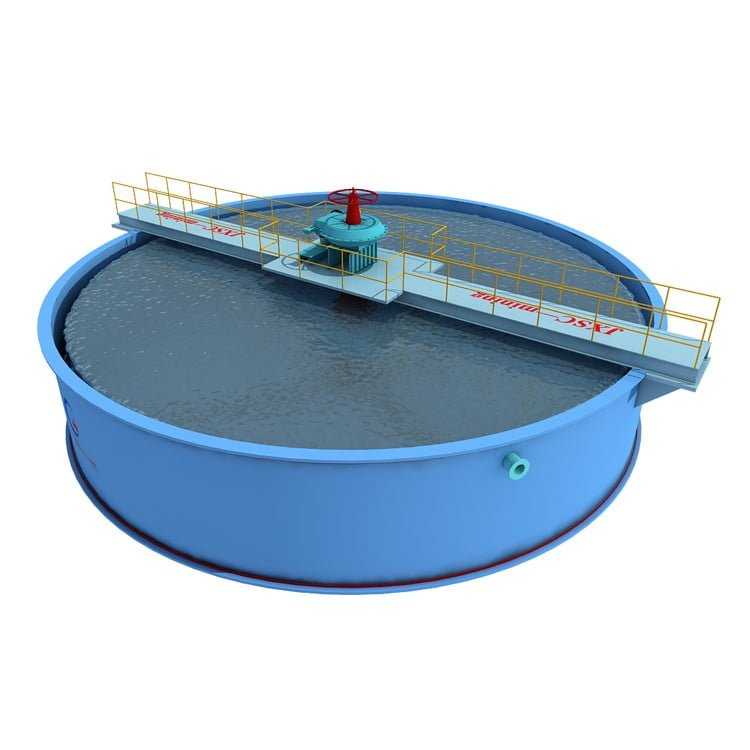

thickener

rotary dryer

Filtration

Filtration is the separation of a suspension into a solid filter cake and a liquid filtrate by passing it through a permeable filtering material. Important factors in this process are the properties of the suspension (e.g., size distribution, concentration), the properties of the filtering materials (e.g., the width and shape of pores), and the forces applied to the suspension. Filtration is carried out in gravity filters (screens, dewatering bins), in centrifugal filters (screen centrifuges), in vacuum filters (drum cell filters, disk filters), or in pressure filters (filter presses). Such devices make it possible to produce filter cakes containing 8 to 15 percent moisture.

Thickening

In the process of thickening (also called sedimentation), the solids in a suspension settle under the influence of gravity in a tank and form a thick pulp. This pulp, and the clear liquid at the top of the tank, can be removed continuously or intermittently. In comparison with filtration, thickening offers the advantage of low operation costs; on the other hand, it has the disadvantage of leaving a higher moisture content in the pulp. For this reason, the dewatering of pulps containing fine particles often involves a combination of thickening and filtration. The thickening of finely grained pulps is often aided by the use of flocculating agents.

Drying

The removal of water from solid materials by thermal drying plays a significant role in modern mineral processing. A great number of dryer types are available. Convection dryers, employing a flow of hot combustion gases to remove moisture from a pulp stream, are the most common. To this type belong rotary drum, conveyor, and fluidized-bed dryers.

Contact Us Now

Please fill out the contact form below to get the quotation price and engineer help.

We will response your request within 24 hours.