Gold Centrifugal Concentrator

Capacity: 0-100 TPH

Feeding: 0-6mm

Application: alluvial gold, etc

Products display

Overview

The centrifugal concentrator rotates at a high speed, generating a high “G” force, which can separate small gravity recovery gold (less than 50 microns), which was of previously unrecoverable with traditional mineral jigs, spiral separator, and gravity tables.

In recent years, the application of centrifugal force has proved to be an effective technology for recovering fine and heavy minerals. The centrifugal force acting on the mineral particles can reach 50 times its own gravity, thus significantly increasing the sedimentation speed of the particles. As the intensity of the centrifugal force increases, the size of the particles that can be captured becomes finer.

https://www.youtube.com/watch?v=ZVhTZvj5pt8

The centrifugal concentrator can be used to recover the tailings of chromite, gold, scheelite and other heavy minerals, so as to make better use of mineral concentrates. Their operating and equipment costs are relatively low. Thanks to its less environmental impact and good recovery of fine-grained minerals, the application of centrifugal concentration has become increasingly important worldwide.

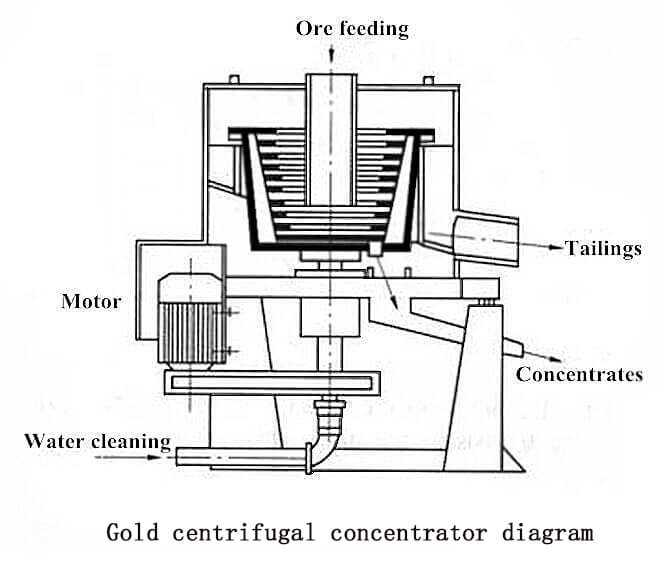

working principle of gold centrifugal

The gold centrifugal concentrator is a gravity-enhancing device. The feed slurry is introduced into a rotating drum, and the impeller rotates to form a high-gradient centrifugal field. The ore particles flow on the inner wall of the rotor and are continuously layered and deposited on the smooth inside the centrifuge wall.

The lighter particles outside the bed are removed from the rotor assembly due to their lower specific gravity or smaller size. Heavy particles remain in the concentration zone, where the concentrate is cleaned with fluidized water.

A rotor spins the bowl, which throws the feed coming into the center against the walls of the bowl. Light and fine particles are carried out of the bowl with the tailings while heavy and coarse particles are collected and removed from the bowl. Industrially they can operate as batch or continuous units, with pores opening intermittently to collect concentrate.

models & specifications

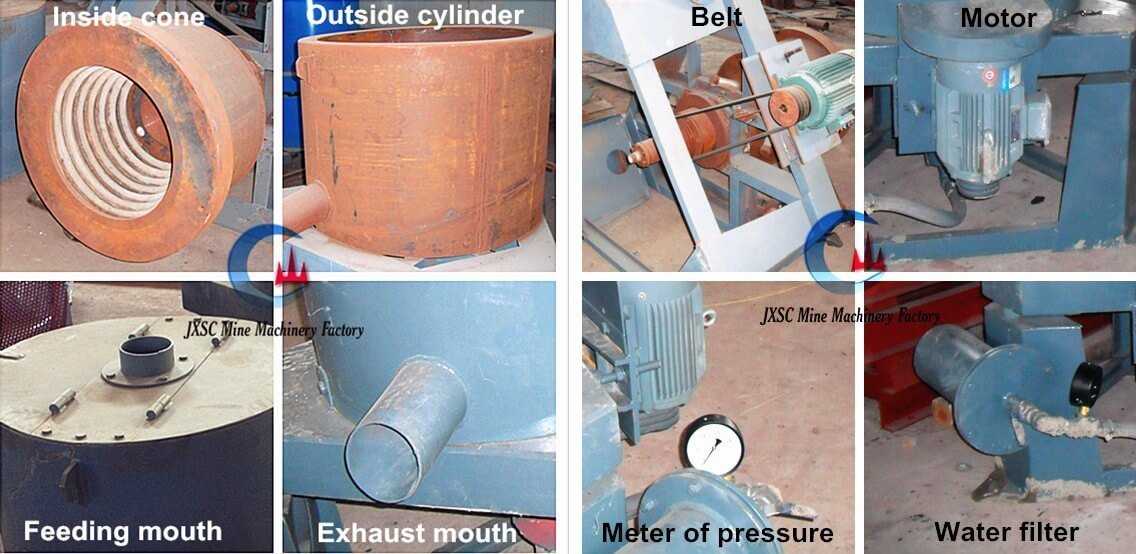

Parameter Replacement Structure Parameter

Replacement

Structure