Providing all kinds of concentrators used in gravity separation

The gravity separation method sorts minerals according to the difference in mineral relative density (usually called specific gravity).

Gravity Separation EquipmentAll kinds of gravity separators

Heavy minerals separationMineral Jig Concentrator

Fine beneficiationShaking Tables

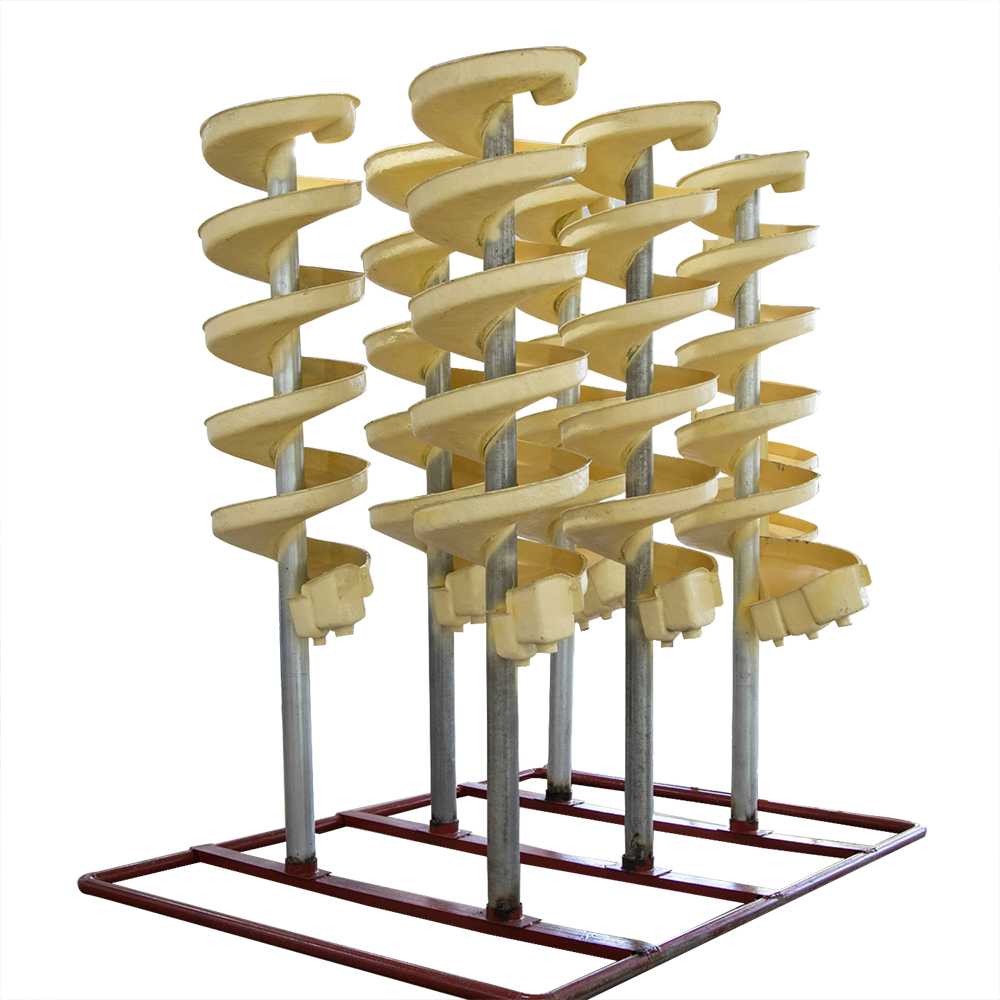

Economic / Minium maintainenceSpiral Separator

Equipment for processing and recovery gold ores

Talk with JXSC’s mining experts to get more help, fell free to conslution!

Gravity separation is a important mineral recovery method and has been the main beneficiation sector used in gold mining plants, alternatively ahead of other processes such as flotation and cyanidation.

Gravity separation is an environmentally friendly beneficiation method that relies on water flow and gravity to separate target value minerals and gangues. It can recover gold from high grade gold particles, as well as the lower grade sulfide particles. The main gravity beneficiation equipment are jig, shaking table, spiral separator, gold concentrator.

Considering its low-cost, ease of operation, and eco-friendly nature, gravity separation techniques are widely used in mineral beneficiation practices.

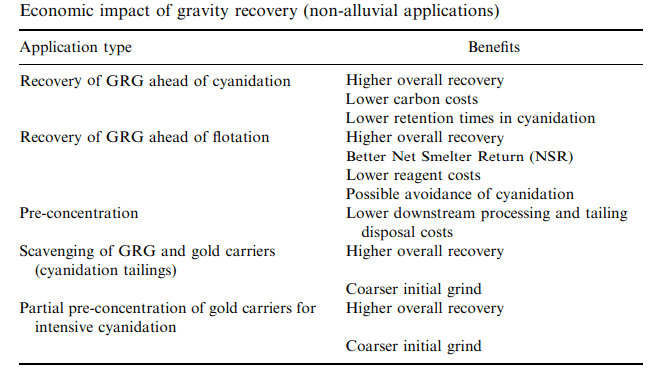

economic impact of Gravity separation

Concentrate processing methods range from gravity separation to amalgamation. In many cases, cyanidation is also used to recover gold from concentrate. Due to health and environmental issues, the amalgamation method has gradually been eliminated. Despite the high recovery rate, strong cyanide has never achieved high acceptance due to the lack of commercial units.

Gravity separation equipment, such as shaker table, relative mercury amalgamation method and cyanidation method are gradually accepted despite their lower efficiency.

For all applications over 95%, the purpose of gravity recoverying for gravity-recoverable gold is to enhance cyanidation or flotation, thereby increasing the total gold recovery rate, while slightly reducing the cost of the pharmaceutical part.

Traditionally, cyanide aqueous solutions are used to treat ores where fine particles of gold are present, while gravity separation can be used to recover free and crude gold from ores. In particular, prior to flotation and/or cyanidation, gravity recovery of coarse gold is an attractive option, which has the potential to maximize the net recovery rate of the smelter and improve the overall gold recovery rate.

The centrifugal gravity separator can effectively recover even fine gold particles, which further expands the scope of gravity application in gold milling practice.

Although gravity beneficiation as an independent operation process usually does not have the same high recovery rate as flotation or cyanidation of the whole ore, it is still a good choice to use gravity equipment alone or in combination with these processes.

Types of gravity separation equipment

Throughout the history of mineral processing, many different types of gravity separation devices have been used. The working principle of these gravity separation equipment is based on the density difference between valuable and gangue minerals.

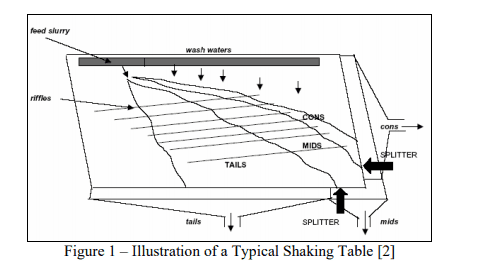

Shaking table

More than a hundred years ago, the Wilfley shaker table was introduced, and is still used in gravity processing flow today. Due to its low capacity (less than 2 tph), the shaker is usually placed after the centrifugal concentrator, jig and spiral classifier, and final upgrade the mineral concentrate produced by former equipment, thus to further improve the gold recovery rate.

The density of the feed slurry is usually kept below 40% by weight to obtain a optimal performance, and the slurry is fed from the top corner of the table, and separated based on the difference in particle density and size.

particle segregation occur on the vibration action of table, which shake back and forth at right angles to the slope of the table.

The shaking of the shaker back and forth causes the combined effect of table vibration and water washing to cause fine weights to slide across the surface of the table, thereby reporting the concentrate to the uppermost part of the table edge. The lower-density gangue remains near the surface of the slurry, and with the help of washing water, it is washed across the shoals towards the tail channel under the table. An intermediate stream is also produced, which is usually recycled back to the grinding circuit for further release.

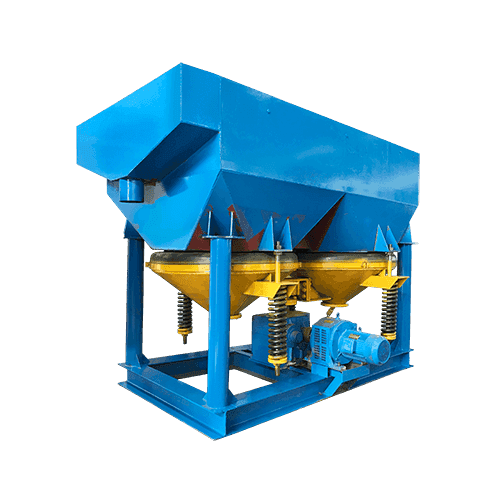

Jig

The main parts of the jig are ragging screen, diaphragm and water storage valve.

Slurry of different density is fed to the top of the fixture in the direction of the ragging screen. Fluidized water through the screen directly upward to the jig bed, make the jig bed loose and separation. The diaphragm produces pulsating and expanding movements on the bed, causing light and heavy particles to separate.

The heavier coarse particles fall down to the concentrate through screen, while the lighter fine particles report to the tail in the form of overflow. The crushed material is located on top of the crushed material screen and is usually selected based on the density, which is between valuable minerals and gangue materials.

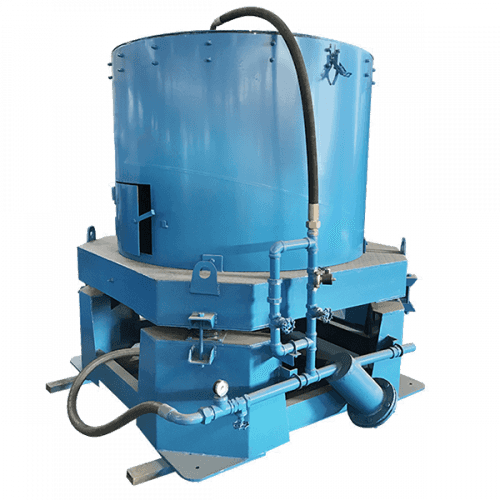

Gold concentrator

There are continuous and semi-continuous centrifuges, but more than 90% of the concentrators are semi-continuous concentrators.

Although the feed must be stopped periodically to clean and remove the concentrate from the drum, these batch processing units can continuously discharge the tailings. Usually the yield of concentrate is less than 0.1%, so it can produce extremely high-grade smelter products.

The Knelson concentrator and Falcon concentrator were introduced in the 1980s, are the most widely used of the two major centrifugal concentrators. with different capacity, and maximum recovery rate.

gravity separator selection

In order to maximize the effects of gravity, gravity separators with different recovery capacity should be considered.

Through a combination of gravity concentrators and or flotation, the mixed concentrate contains high amounts of gold and can now be treated easily with an expected leaching recovery rate of more than 95 per cent.

After decades of research and development, we have summarized and summarized experiences of various gravity concentration equipment and their applications.

The following are some representative applications

1. Jig: gold-containing sulfide, tin, mineral sand, chromite, iron, coal, etc.

2. Centrifuge: gold, copper, platinum, chromite, coal, etc.

3. Shaker: coal, chromite, manganese, etc.

4. Heavy medium separator: coal and minerals

5. Spiral concentrator: chromite, sand, coal, iron, etc.

6. Shaking table: chromite, gold, rare earth ore

7. Multi-gravity separator: chromite, coal, graphite, rare earth ore.

Contact Us Now

Please fill out the contact form below to get the quotation price and engineer help.

We will response your request within 24 hours.