Hammer Crusher

Capacity: 1-75t/h

Feeding: <400mm

Discharge: 0-10mm

sale@jxscmachine.com +86-13879771862 Get the price

Products display

Overview

The hammer crusher is divided into ordinary hammer crusher and ring hammer crusher. The ring hammer is generally used in coal, coke and other industries. Ordinary hammer type machines are generally indicated by PC prefixes in English, and ring hammer crushers are generally indicated by PCH in English prefixes.

Hammer crusher has the characteristics of simple structure, large crushing ratio, high production efficiency, etc. It can be used for dry and wet crushing. It is suitable for medium hardness and brittleness in mining, cement, coal, metallurgy, building materials, highways, combustion and other departments.

https://www.youtube.com/watch?v=Th31pL7iNRk

Working principle

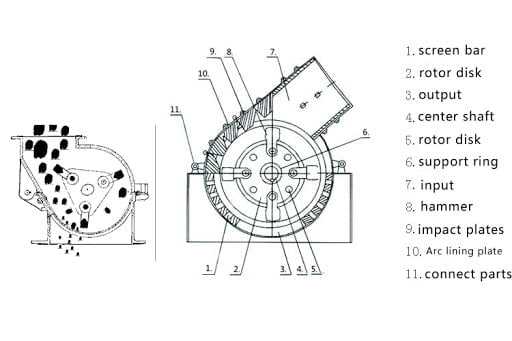

The motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the machine from the upper feed port and crushed by the impact, shearing and grinding of the high-speed hammer. In the lower part of the rotor, there is a sieve plate, the particle size of the crushed material that is smaller than the size of the sieve hole is discharged through the sieve plate, and the coarse particle size larger than the sieve hole size is retained on the sieve plate to continue to be hit and grinded by the hammer, and finally passes the sieve plate out of the machine.

specifications

Parameter Structure Replacement Parameter

Structure

The main working part of a hammer breaker is a rotor with a hammer (also called a hammer head). The rotor is composed of a main shaft, a disc, a pin and a hammer. The motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the machine from the upper feed port and crushed by the impact, impact, shearing and grinding of the high-speed hammer. There is a sieve plate at the lower part of the rotor. During crushing, the particle size smaller than the sieve hole size is discharged through the sieve plate. The coarse particle size larger than the sieve hole size is retained on the sieve plate to continue to be hit and ground by the hammer, and finally passes through the sieve plate Out of the machine.

types of hammer crusher

★Single-stage hammer crusher

The single-stage hammer crusher is a heavy hammer crusher, also known as a composite hammer crusher, which is mainly used for limestone crushing operations. The large single-stage hammer crusher can directly crush a 1 meter diameter limestone to about 20mm, with Powerful crushing ability. The single-stage hammer crusher has a large number of applications in the cement industry.

★Vertical shaft hammer crusher

The biggest advantage of the vertical shaft hammer crusher is that there is no screen plate structure, and there is no clogging. However, there is no large-angle counterattack process between the hammerhead of the vertical shaft and the liner, so the effect of fine crushing is slightly lower. The hammer head is an integral structure, so repair and maintenance are more cumbersome.

★Efficient hammer crusher High-efficiency hammer crusher is mainly used for fine crushing of materials and is an important equipment in the field of fine crushing. Taking the high-efficiency hammer crusher as an example, the hammer head is a split structure, and the hammer head and the hammer handle are connected by bolts. The material of the hammer head is made of chrome-molybdenum alloy with high wear resistance, and the wear resistance of the hammer head is the most durable among all hammer breaks. The split structure of the hammer head makes the replacement of the hammer head very convenient.

★Reversible hammer crusher Mainly used for fine crushing of soft materials and low abrasive materials. The rotor has the ability to run in both positive and negative directions, which can greatly increase the life cycle of the hammer head and reduce the number of times to replace the hammer head.