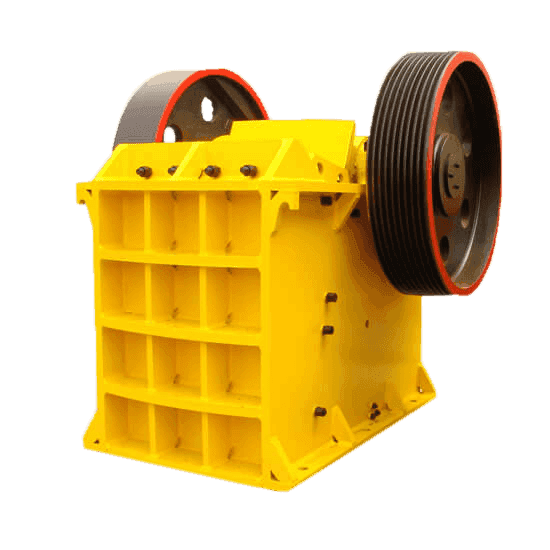

Jaw Crusher

Capacity: 1-1120t/h

Feeding Size: <800mm

Discharge Size: 10-350mm

Products display

Overview

For more than a century, the jaw crusher has been the main crusher in the mining and quarrying industry, and to a large extent, this situation will continue.

Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries. Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with the capacity range of 1-1000tph. There are two types of feeding opening design, rectangular and square shape.

The primary jaw crusher is usually designed with a square opening, while the secondary jaw crusher is designed with a rectangular opening. However, not all jaw crushers conform to this general rule.

https://www.youtube.com/watch?v=SEYE7MQOrmc

The jaw crusher is composed of two jaws, one is fixed firmly with the crusher frame, and the another is being mount by a pitman mechanism. The moving jaw moves backwards and forwards quickly between a small throw to crush the ore.

As the moment of jaw plate is small, the crushing can be done in one stroke. Considering the high wearing rate caused by the load action on the plate, two plates are generally made of high wear resistant material like manganese steel. A heavy flywheel can provide a required inertia, a smooth reciprocating action of the moving jaws and help crush the hard material.

working principle

The jaw crusher typically crush material by using compression. The ROM is fed between two solid pieces of metal, one of which (moving jaw) move towards the rock, and causes compression. The rock is crushed because its breaking point is lower than the opposing metal piece.

The jaw crusher is a typical compression crusher, it crushes the feed by moving plate toward the fixed plate. Due to the applied great pressure and shear force, the strain exceeds the elastic limit of the raw material, and the material will break. Load acts on the plate the wearing rate is high hence the jaw crusher is rugged in design and equipped with replaceable high tensile wear resistant manganese or other alloy steel sheet.

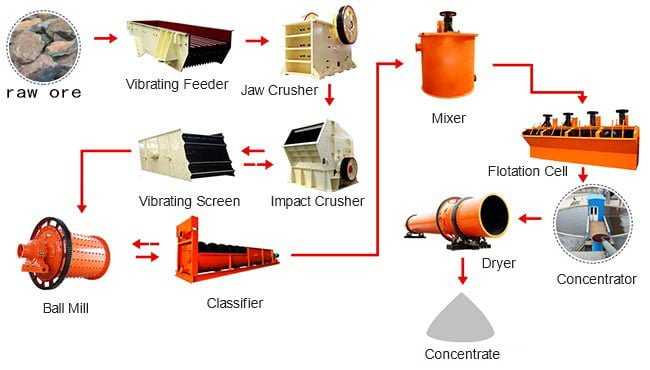

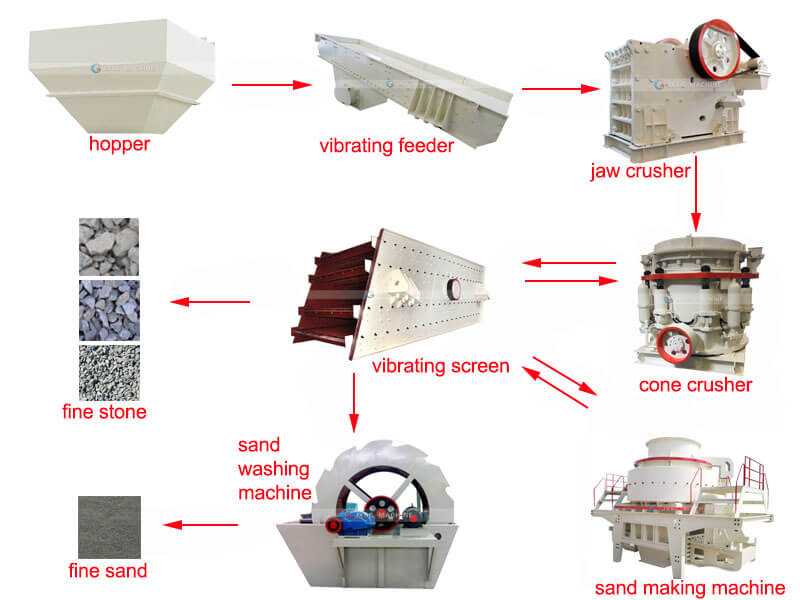

Crushing solution

Jaw crusher in the mineral processing plant

stock bin -> feeder -> jaw crusher -> cone crusher -> vibrating screen -> ball mill -> classifier -> concentrator -> mineral concentrate

Jaw crusher in the sand crushing plant

stock bin -> feeder -> jaw crusher -> cone crusher / impact crusher -> vibrating screen -> sand washer -> VSI impact crusher -> finished product

models & specifications

Parameter Replacement Structure Features Parameter

Replacement

Structure

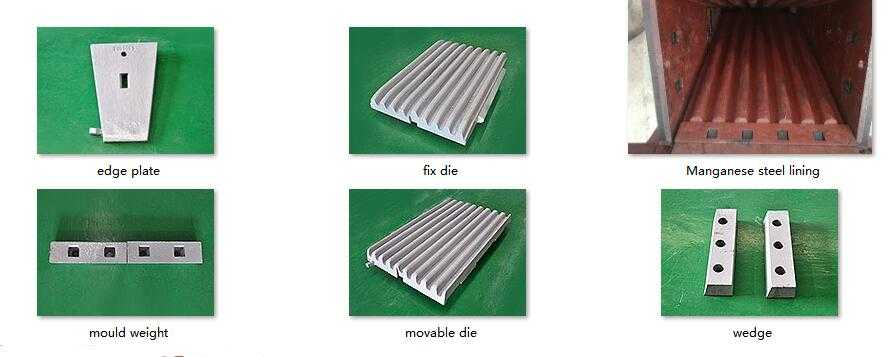

Main parts

▶ bowl liner ▶ eccentric shaft ▶ mantle ▶ The jaw dies are easy to wear and must be replaced regularly. ▶ The jaw crusher is equipped with a hydraulic regulating system to adjust the closed side setting and thus affect the product particle size distribution.

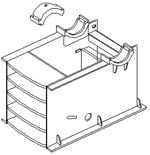

1. Base Frame

The frame of the jaw crusher is divided into two types: welding type and assembly type. The small and medium jaw crushers are generally welded, and the large capacity crushers are generally assembled.

The frame of the jaw crusher is divided into two types: welding type and assembly type. The small and medium jaw crushers are generally welded, and the large capacity crushers are generally assembled.

The welding type adopts the welding method of large arc transition fillet and low stress area, which greatly reduces the stress concentration, ensures the equal strength of the rack in all directions, and has the characteristics of impact resistance, uniform force, and low failure rate.

The assembly type adopts a modular, welding-free frame structure design with high strength and reliability. At the same time, the assembly design of the whole machine is more convenient for transportation and installation. It is especially suitable for installation in small and difficult transportation places such as underground mines and high-altitude mines.

2. Toggle plate

The brackets are welded parts that have been accurately calculated. It is not only a transmission component, but also a safety part of the crusher. When the unbreakable material falls into the crusher and the machine exceeds the normal load, the toggle plate will break immediately and the crusher will stop working to avoid damage to the entire machine. The toggle plate and toggle pad use rolling contact method, under normal use, there is little friction, just apply a layer of grease on the contact surface.

The brackets are welded parts that have been accurately calculated. It is not only a transmission component, but also a safety part of the crusher. When the unbreakable material falls into the crusher and the machine exceeds the normal load, the toggle plate will break immediately and the crusher will stop working to avoid damage to the entire machine. The toggle plate and toggle pad use rolling contact method, under normal use, there is little friction, just apply a layer of grease on the contact surface.

3. Adjustment system

The adjusting part is a mechanism for adjusting the size of the discharge port and compensating the wear between the jaw plate, the toggle plate and the toggle pad.

The adjusting part is a mechanism for adjusting the size of the discharge port and compensating the wear between the jaw plate, the toggle plate and the toggle pad.

The assembly process of the adjustment components: the toggle pad is fixed to the adjustment seat by angle steel and bolts, and the adjustment gasket is placed between the adjustment seat and the lower frame.

Features

★Advanced crushing process, energy saving and high efficiency The compound pendulum jaw crusher adopts the most advanced crushing technology and uses advanced digital component processing equipment to make the internal structure precise. There is no dead zone in deep cavity crushing, and the material will not block in the crushing cavity, which improves the production efficiency. The energy saving of a single machine is 15% to 30%, and the energy saving of the system is more than doubled.

★High wear resistance of parts The parts are made of the highest quality materials, which enhances the compression resistance and wear resistance of the parts, reduces certain wear and tear, and extends the service life of the entire equipment. Among them, the movable jaw is made of high-quality cast steel parts, and the eccentric shaft is processed by forging blanks, etc., which increases the reliability of the equipment and is highly efficient and durable.

★Flexible and versatile, with a wide range of applications The wide adjustment range of the discharge port increases the flexibility of the equipment and can meet various processing needs of users. Moreover, the equipment has a reasonable structure and a small footprint, which can play the largest role in a limited space. Therefore, it is widely used in various crushing processes in many industries.

★The structure is simple and easy to operate, and the maintenance is convenient and fast After reasonable design, while improving the performance of the machine, the overall structure of the equipment is simple and efficient, and the crushing ability is enhanced. The whole equipment is easy to operate during use, which makes daily maintenance work more convenient and quick, and reduces downtime and maintenance time. Among various crushing equipment, jaw crusher is widely used. The advantages of jaw crusher are simple design, high reliability, small overall size and weight, and easy maintenance and repair.