Shaking Tables

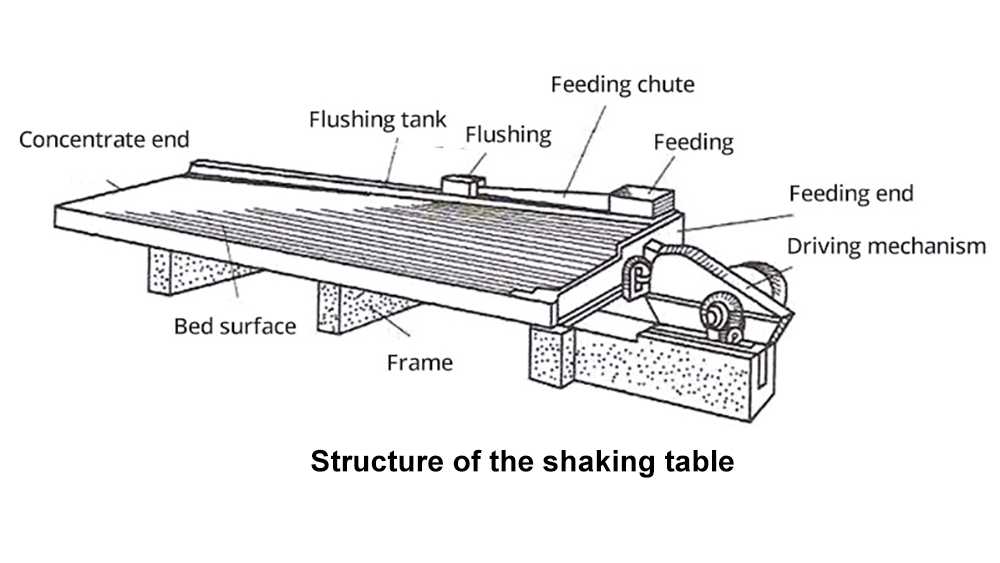

Shaking Table Structures

Overview

Shaking tables are one of the oldest gravity separators in the mineral processing industry, capable of handling minerals and coal of 0-2mm.

Shaking tables are rectangular-shaped tables with riffled decks across which a film of water flows. The mechanical drive imparts motion along the long axis of the table, perpendicular to the flow of the water. The water carries the particles of the feed in slurry across the riffles in a fluid film. This causes the fine, high density particles to fall into beds behind the riffles as the coarse, low-density particles are carried in the quickly-moving film. The action of the table is such that particles move with the bed towards the discharge end until the end of the table stroke, at which point the table rapidly moves backwards and the particles’ momentum propels them still forward.

In gravity separation, the shaking tables are the most widely used and very efficiency sorting equipment for fine ore separation.

The shaking table beneficiation is not just applicatied as an independent beneficiation method, but it also often combined with other beneficiation methods such as jigging, flotation, magnetic separation by centrifugal concentrator, spiral classifier, spiral chute and other beneficiation equipment.

The capacity of the shaking table is about 0.5 t/h. 1.5-2TPH depending on the particle size of the process. In chromite processing and dressing industry, it is usually dozens of shaking table series or parallel installation to deal with excess tons. Therefore, the required installation space, equipment control difficulties due to the increased number of installations and the need for more automated processes have brought new challenges to the process design.

All Types of shaking tables to choose from

As a shaking table manufacturer, JXSC provides all kinds of popular types of shaker tables for sale.

Our Shaker tables by deck numbers:

- Single deck shaker tables

- Double deck shaker tables

- Mult deck shaker tables

Customizable deck for your need.

1. Laboratory small shaker table, deck size 1100*500*430mm

2. Standard shaker table, deck size 2100*1050*850mm

3. 6S small shaker table, deck size 4500*1850*1560mm

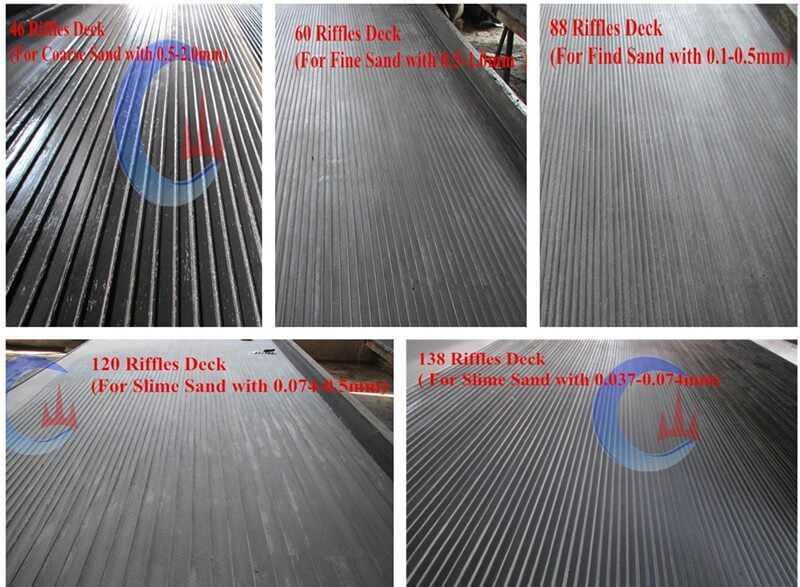

According to different feed particle size, 6S shaker is separately suited for coarse sand, fine sand, slime. There are 5 different grooves available: 46/60/88/120/138.

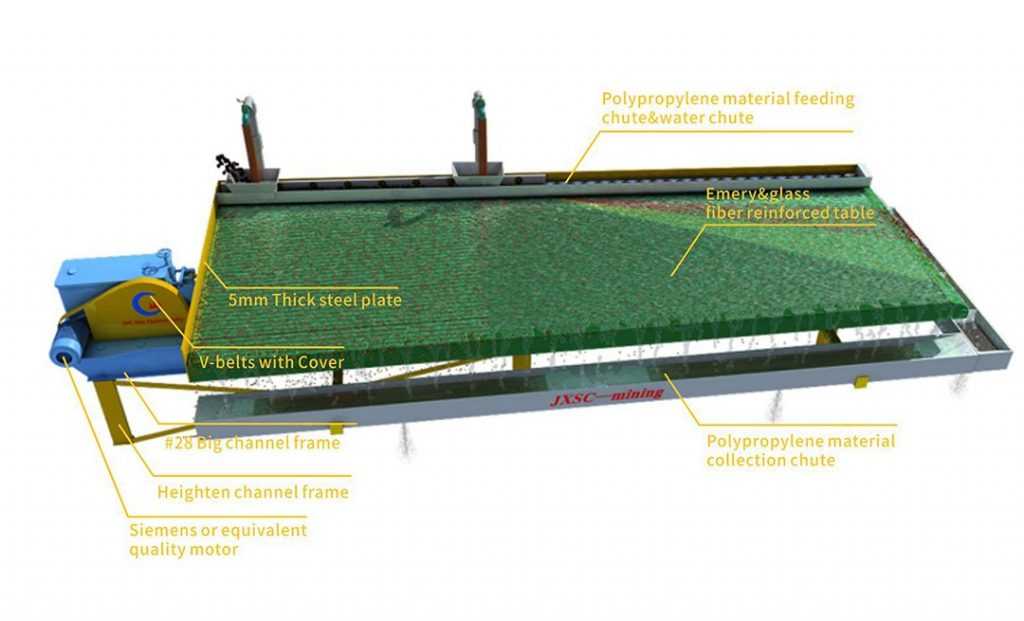

Hightlight of JXSC gold shaking tables

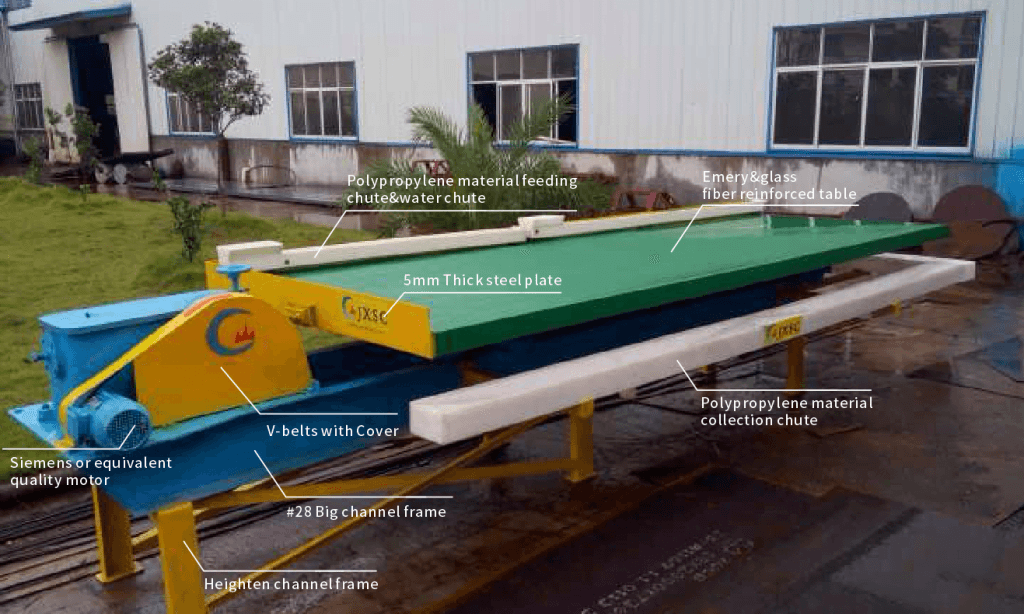

Compared with competitor’ shaking table,our shaking table has below outstanding advantages:

- Big channel frame, very strong steel base structure( other companies use small channel frame)

- Polypropylene materials feeding chute and collection chute.(other companies dont have )

- Heighten steel stand,making it more convenient when feeding materials.

Add cover for belt wheel. - Use top quality fiberglass deck,more wear-resisting.

- Has various grooves on the table for your choice. We will recommend the best grooves to you according to your gold size.

models & specifications

Parameter Replacement Structure Parameter

| Deck type | Unit | Course sand | Fine sand | Slime Deck | Three different kinds of decks are available | |||

|---|---|---|---|---|---|---|---|---|

| Beneficiation Area | m2 | 7.6 | 7.6 | 7.6 | 4.08 | 1.95 | 0.5 | |

| Deck Size | Length | mm | 4450 | 4450 | 4450 | 3000 | 2100 | 1100 |

| transmission end width | mm | 1855 | 1855 | 1855 | 1320 | 1050 | 500 | |

| Concentrate end width | mm | 1546 | 1546 | 1546 | 1100 | 850 | 430 | |

| Maximum Feeding Size | mm | 2 | 0.5 | 0.15 | 0.1-2 | 0.074-2 | 0.074-2 | |

| Feeding Amount | t/d | 30-60 | 10-20 | 15-25 | 0.4-1.5t/h | 0.3-0.8t/h | 0.05-0.2t/h | |

| Feeding Density | % | 25-30 | 20-25 | 15-25 | 10-30 | |||

| Stroke | mm | 16-22 | 11-16 | 8-16 | 6-30 | 12-28 | 9-17 | |

| Frequency | f | 45-48 | 18-53 | 50-57 | 210-320 | 250-450 | 280-460 | |

| Water added | t/d | 80-150 | 30-60 | 10-17 | 0.3-1.5t/h | 0.2-1t/h | 0.1-0.5t/h | |

| Transverse slope of Deck | ° | 2° 30-4° 30 | 1° 30-3° 30 | 1° -2° | 0 -10° | 0 -8° | 0 -10° | |

| Longitudinal slope of Deck | ° | 1.4 | 0.92 | —— | —— | —— | —— | |

| Cross-section Shape of Deck | rectangular | saw tooth | triangle | Avaliable rectangular, saw tooth, triangle | ||||

| Motor Power | KW | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |

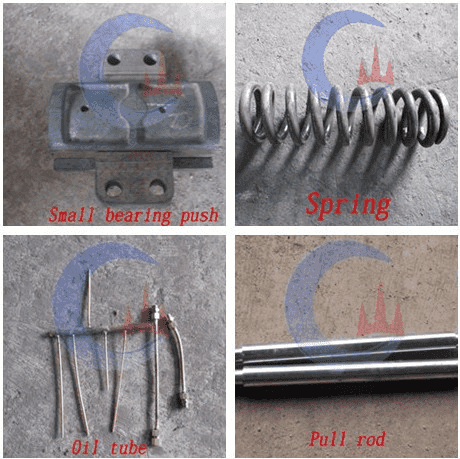

Replacement

Main wear parts are: bearing bush, tubing, spring, oil seal, belt

Others include: oil pump, screw, connector, motor, bed surface

Structure