Spiral Separator

Capacity: 0.15-8 TPH

Feeding: 0.3-0.02mm

Application: fine-grained iron, tin, etc

sale@jxscmachine.com +86-13879771862 Get the price

Products display

Overview

FRP spiral chute combines the advantages of spiral concentrator, spiral chute, shaker, and centrifugal concentrator, and is the best equipment for mining and beneficiation, especially the sand mining in the seashore, riverside, sand beach and stream. Spiral chute is used to select fine-grained iron, tin, tungsten, tantalum, niobium, gold ore, coal mine, monazite, rutile, zircon and other metal and non-metallic minerals with sufficient specific gravity difference. The sorting process is stable and easy to control, the allowable range of feed concentration is wide, the enrichment ratio is high and the recovery rate is high.

https://www.youtube.com/watch?v=XLv55jxqa2w

The spiral chute mainly uses the inertial centrifugal force generated by the minerals of different densities in the spiral rotation to achieve the separation of light and heavy minerals. Because of its simple equipment structure, low power consumption, and large processing capacity, it is widely used in the gravity separation process. Chute beneficiation belongs to bevel flow separation process. The slurry is given to a certain inclined chute. Under the impetus of water flow, the ore particles are loose and layered. The upper layer of light minerals is quickly discharged from the tank, and the lower layer of heavy minerals is retained in the tank or discharged from the lower part at a low speed. After that, concentrate and tailings are obtained.

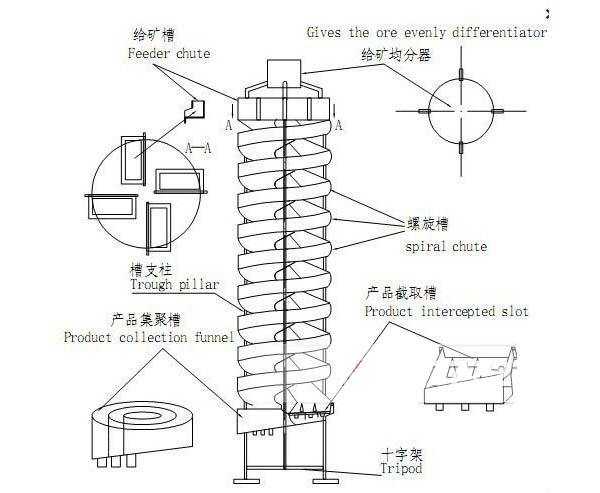

Main parts

The spiral chute is composed of six parts: ore feed divider, ore feed groove, spiral groove, product intercepting groove, ore receiving hopper and groove bracket.

The spiral groove composed of spiral pieces is the main component. The spiral pieces are made of glass steel (glass fiber reinforced plastic) and are connected together by bolts. The glass fiber reinforced plastic spiral sheet is light and strong, and has a wear-resistant layer on the surface, which is durable.

The first end of the trough is equipped with a multi-tube ore-feeding splitter, which is evenly distributed and easy to control. The evenly divided pulp is slowly fed to the spiral groove surface by feeding minerals.

The end of the spiral groove is equipped with a valve block type product intercepting groove, which divides the sorted ore flow into several products according to grade. Use the position of the adjustment valve block to change the interception width of each product.

The receiving hopper is a concentric ring cylinder, which collects and exports multiple intercepted streams according to products.

models & specifications

Parameter Application Structure Features Parameter

Application

The spiral chute is based on the density difference between the minerals to achieve the purpose of sorting, and at the same time, it can recover the iron minerals that have been separated by monomers at a relatively coarse particle size level (generally not affected by the type and magnetic properties of iron minerals, surface) chemical properties etc.).

Therefore, it can be widely used in various combined processes of processing magnetite (including roasted magnetite), hematite and other minerals such as weak magnetic-strong magnetic-flotation. It can supplement, assist, improve and improve processes such as magnetic separation, flotation, centrifuge reselection, and fine sieve.

Structure

Features

The main advantages of the chute are the simple structure of the equipment, the low investment and production costs, and the coarse and medium-grain chute also have a high processing capacity. The disadvantage is that the separation accuracy is low, so it is suitable for use as a rough separation equipment. It is widely used in the treatment of tungsten, tin, gold, platinum, iron and some rare metal ores, especially in the treatment of low-grade sand ores.

① It has no moving parts and consumes no power;

② The equipment covers a small area and has a large processing capacity;

③ Because the quality score of the ore is high and no washing water is added, water is saved;

④ The conditions required for operation (such as ore feeding granularity, quality score, etc.) are not harsh, and the selection index is relatively stable.

⑤ Light weight, moisture-proof, rust-proof, corrosion-resistant and noise-free.