High-Frequency Vibrating Screen

Capacity: 10-500t/h

Moto power: 2.2Kw-30Kw

Layer:1-4 available

Products display

Overview

Separate crushed materials and gravel into different sizes through large screens or industrial screens. As part of the crushing operation, coarse screens called grizzly bears or oxen are used to separate too large or too small materials from raw materials.

Screens have static, horizontal and cylindrical screens, but today, most factories use inclined vibrating screens. The screening equipment determines the clear and reliable material separation, which provides the basis for the subsequent mineral processing.

https://www.youtube.com/watch?v=PWjzN7h-QzA

working principle

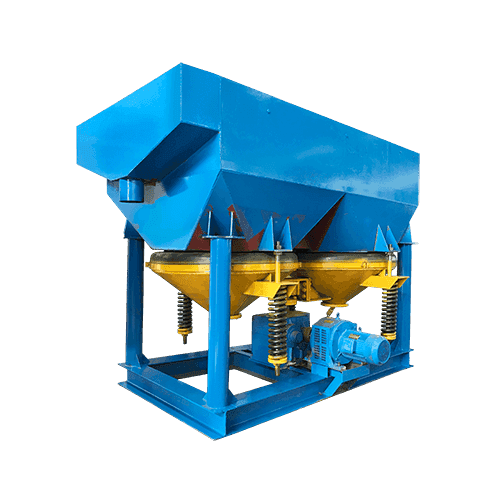

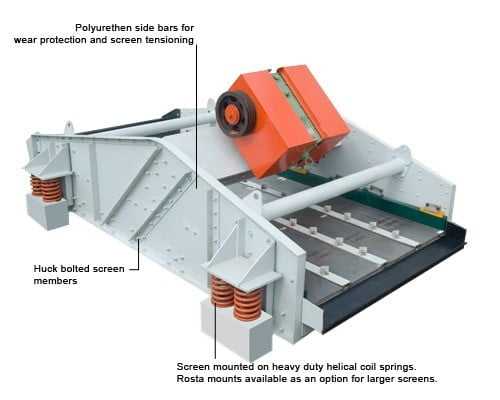

Main parts of high frequency vibrating screen are mainframe, screen, electric vibrators, electric motor, rub spring and coupler.

The screening decks are capable of single to triple decks, greatly improve the screening efficiency and capacity. Besides, providing a thin and loose bed of particles, which as well as do a good effect on the screen.

Sieving is one of the oldest and most widely used physical size separation methods and is widely used in industry. In the continuous screening process, high frequency and low amplitude features lead to the vertical elliptical movement, the particles that fall from the feed hopper and reach the surface of the screen are sorted under the action of gravity. Oversized particles rebound along the screen, and most undersized particles pass through the holes.

Comparation

circular vibrating screen & high frequency vibrating screen

High frequency vibrating screen is the most important screening machine mainly used in the beneficiation industry. They are used to separate materials containing solids and crushed ores with a particle size of less than 200 μm. Wetting or drying materials can be sieved.

Unlike the ordinary vibrating screen, the frequency of high-frequency screening is controlled by an electromagnetic vibrator installed above the surface of the screen and directly connected to the surface of the screen, and the vibration frequency is adjustable.

High-frequency vibrating screens are usually operated at an angle of inclination, traditionally varying between 0 and 25 degrees, up to 45 degrees. In addition, it should operate at a low stroke with a frequency range of 1500-7200 RPM. Before using a high-frequency screen, it is usually necessary to pretreat the feed, because the holes in the screen are easily blocked.

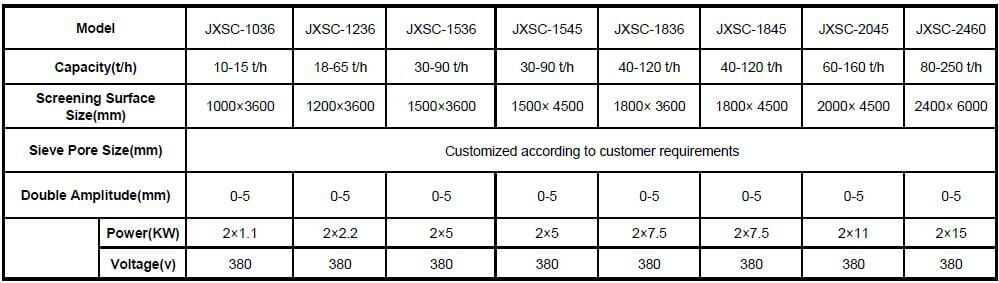

models & specifications

Technical parameter Structure Main parts Features Uses Technical parameter

Structure

Main parts

The limitation of the high frequency vibrating screen is that the fine screen is very fragile and easily blocked. As time goes by, the separation efficiency will decrease and the screen needs to be replaced.

Features

Circular vibrating screen

The multi-layer vibrating screen is specially designed for screening stones in quarries. It can also be used to classify products in coal preparation, mineral processing, building material production, power and chemical industries.

The main advantages of the circular vibrating screen are as follows.

(1) By adjusting the excitation force, the flow rate can be changed easily and steadily.

(2) The circular vibrating screen has stable vibration, reliable operation and long service life.

(3) Simple structure and reliable operation. The relatively light weight and small volume make maintenance easier.

(4) The closed structure of the screen effectively prevents dust pollution.

(5) Low noise intensity and small power consumption are generated during the operation of the vibrating screen.

High frequency vibrating screen

(1) Light, durable structure. The compact high-power vibration exciter is used as the drive. No belt or other accessories are required. The screen is very light but durable.

(2) Adjustable flow rate. The screening capacity can be adjusted with ease because the stroke can be varied by adjusting the unbalanced weight with the most suited number of poles.

(3) Screening capacity can be easily adjusted by adjusting the stroke, frequency, etc.

(4) Stable performance. The high power of vibration makes screen run stable, even when screening adhesive materials.

(5) Accurate screening. According to the specific materials and flow rate, single-layer to triple-layer deck-type groove can be designed according to the screening requirements to achieve accurate and efficient screening.

(6) Simple start, stop. Press the controller button to easily control the start or stop of screening.

Uses

In the beneficiation line of various ores, the high-frequency sieve plays a vital role. The high-frequency sieve sifts out the coarse particles and sends them back to the crusher for crushing. At the same time, the fine-grained materials are discharged in time to avoid excessive crushing caused by re-grinding.

The sieved materials can enter the next stage of beneficiation process. The use of high-frequency sieve can not only meet the requirements of mineral fineness, but also achieve smaller particle size separation, thereby reducing the capacity and overall energy consumption required in the crushing stage. Therefore, the grade of the final product is improved, and a better recovery rate and screening efficiency are provided.

s