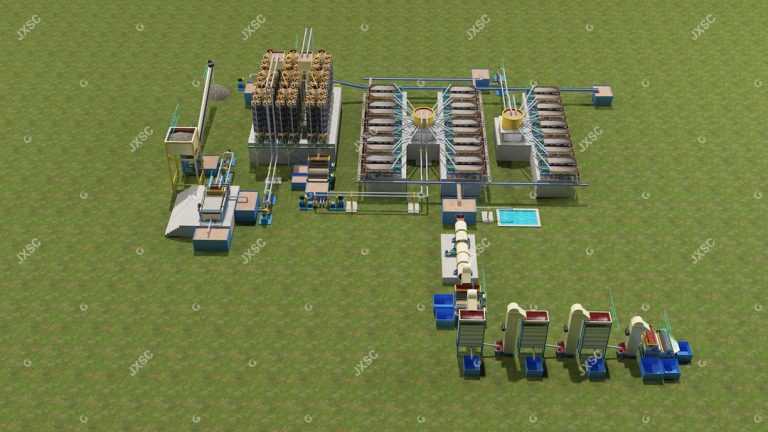

Beach Sand Processing Plant

A full setup processing flow for iron ore washing and beneficiation.

Full Setup Flowsheet for beach sand processing & recovery

https://www.youtube.com/watch?v=BZB0q3BeJJ4

This is a 100 t/h beach sand processing plant, complete plant is configured with the below machines: feeder, vibrating screen, belt conveyor, slurry pump, magnetic separator, spiral chute, shaking table, dryer, electrostatic separator.

Raw ore information as below:

- Capacity 100tph

- Above 2mm impurities are removed

- Need separate rutile, monazite, zircon, ilmenite, magnetite from the beach sand

Flowchart explanation as below:

- Excavator or Loader feed raw sand to raw ore bin, then through the electromagnetic vibrating feeder to feed vibrating screen.

- Vibrating screen with one layer screen with 2mm mesh size, in order to remove above 2mm impurities.

- Below 2mm go to magnetic separator by slurry pump for separating out magnetite

- Output of magnetic separator are sent to spiral chute by a slurry pump. Through gravity separation method to remove light minerals.

- Spiral chute gravity separation plant has two stages: the middling from first stage spiral chute plant go to second stage spiral chute for reprocessing.

- All concentrates from two stages spiral chute plants are sent to 1st double drum magnetic separator for separating out ilmenite.

- Output of 1st double drum magnetic separator are sent to shaking table by slurry pump for removing light minerals by gravity principle.

- Shaking table has two stages: the middling from the first stage shaking table is sent to the second stage shaking table for further processing by a slurry pump.

- All concentrate from two stages shaking table plant is sent to the rotary dryer for drying material.

- After drying, dry materials through hoist machine to 2nd double drum magnetic separator for separating out ilmenite.

- Other minerals from 2nd double drum magnetic separator go to 1st electrostatic separator through hoist machine for separating out rutile, other minerals through hoist machine to 2nd electrostatic separator for separating out rutile, other minerals through hoist machine to 3rd electrostatic separator for separating out rutile.

- Ohter minerals from the 3rd electrostatic separator go to the double roller strong magnetic separator via hoist machine for separating out zircon and monazite.