Hard Rock Gold Mining

JXSC Mining Machinery committed to providing customizable gold mining solutions, with over 3 decades of experience, we help our customers around the world improve their operational efficiency, reduce risks, and increase profitability.

How to benefiation gold from hard-rocks

Beneficiation is the processing of ore to separate the target mineral from the waste rock. Before beneficiation, nearly all crude ore must be reduced in size. Primary crushing reduces ore from 2-4 feet boulders to rocks 8-10 inches in diameter. Secondary crushing reduces the ore into pieces less than 1 inch in diameter. Large rotating cylinders grind the material, creating finely ground mill. Slurry is formed when water is added to finely ground mill.

The type and extent of beneficiation depend on the desired product. Some common types of beneficiation are:

Gravity separation relies on large differences in density between the targetmetal (e.g., gold) and the materials in which it is found. It also requires thatthe target metal cannot be bound to the surrounding rock matrix. Somedevices used in gravity separation are trommels, sluices, spiralconcentrators, cyclones, jigs, and shaker tables.

Floation is adaptable to small particals and commonly used to recover lead,copper, platinum, and zinc. In floatation, the addition of a reagent chemicalto ore slurry causes the minerals to become less dense than the gangue andrise to the top of the tank.

Leaching is the process of extracting a soluble metallic compound from ore. Itinvolves dissolving the ore with a suitable solvent, such as sufuric acid orsodium cyanide solution.

Hardrock Gold Mining & Beneficiation Solutions

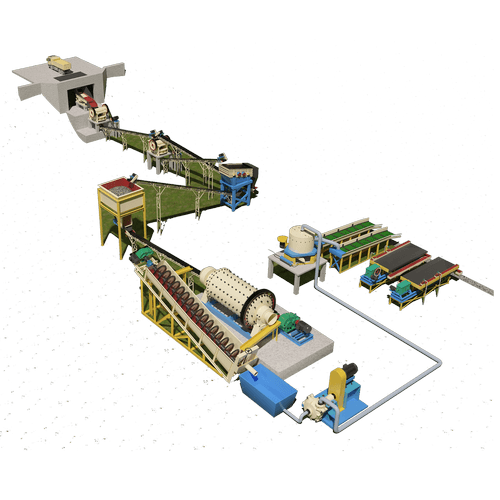

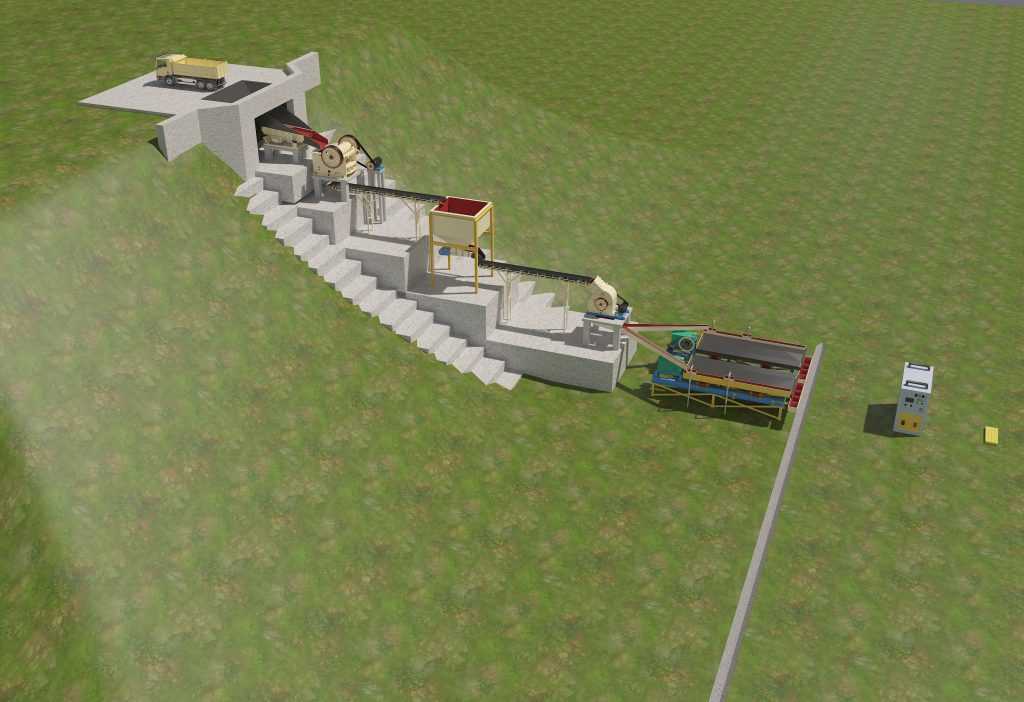

hard-rock gold mining use hammer crusher + shaking tables

This setup is a 5-10tph rock gold process plant use hammer crusher or jaw crusher

It is configured with trough feeder to give materials to a jaw crusher, after jaw crusher grind materials size to be small to hammer crusher .hammer crusher grind materials to be fine then to shaking table to recover gold.

The trough feeder it can feed evenly to the crusher.

The jaw crusher Preliminary crushing of large stones also can be made mobile type as per request.

The hammer crusher the output size is adjustable like 10mm,5mm, etc. for this project it’s grind materials to 0-2mm. also can be made mobile type as per request.

The shaking table is gravity to recovery gold .with very high recovery rate and It is very friendly to the environment

This Plant also can be used for Hard Rock Tin ore/ Coltan ore/ Tungsten Ore/ Chrome

The capacity for this process plant can be customized as per request such as 10tph, 20tph,50tph,100tph, etc

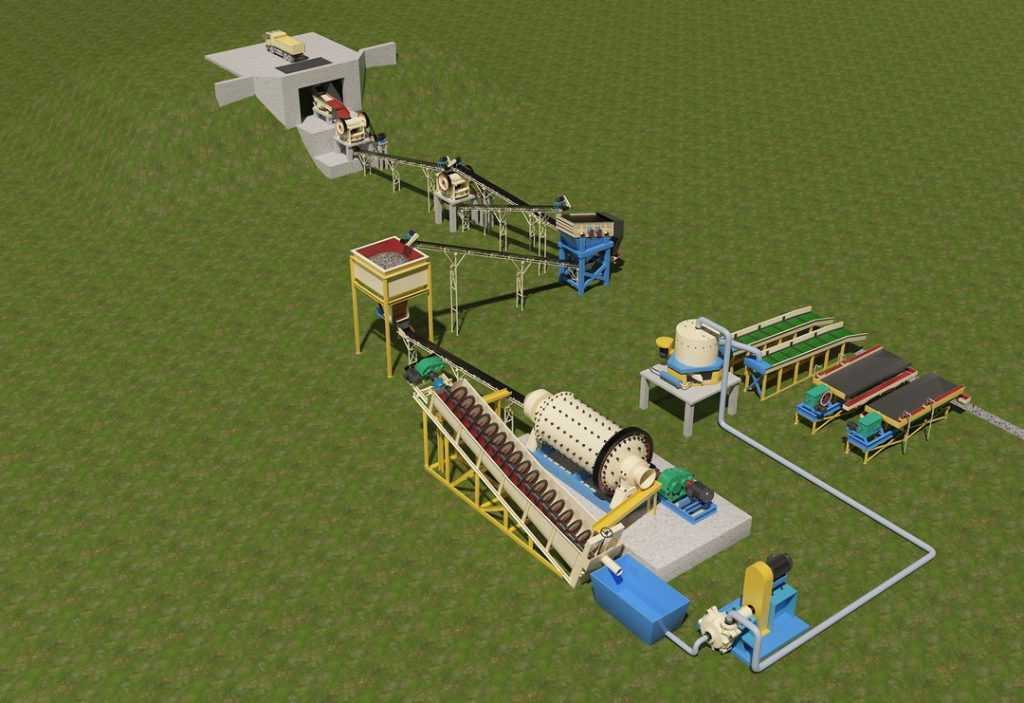

hard-rock gold mining via ball mill + shaking tables

Here is the detail Flowchart Explanation For Rock Gold Processing plant:

1. Loader or Excavator feed raw ore into the hopper;

2. Vibrating feeder feed primary jaw crusher; primary jaw crusher is to crush big stone to medium size.

3. Output of primary crusher sent to fine jaw crusher by belt conveyor; fine jaw crusher is to crush medium sized stone to small size.

4. Output of fine jaw crusher sent to vibrating screen by belt conveyor;

5. Oversized rock is back to fine jaw crusher for further crushing by belt conveyor;

6. Undersized materials sent to one transit ore bin by belt conveyor;

7. Fine ore in transit bin is sent to ball mill via electromagnetic vibrating feeder+belt conveyor. ball mill is to grind ore to powder size.

8. Discharge of ball mill goes to spiral classifier for roughly size separation. Coarse particles will be back to ball mill for further grinding;

9. Fine particles will be sent to the centrifugal concentrator for concentrating fine gold by a slurry pump.

10. Tailings of centrifugal concentrator go to sluice box for recovering more gold;

11. Concentrates of sluice box and centrifugal concentrator are sent to shaking table for fine concentrating gold.

The ball mill + classifier forms a closed-circuit grinding system, which can achieve more than 90% of the discharge to 200 mesh(0.074mm)

So this flowchart is very suitable for recovering fine powder gold in rocks.

hard-rock gold mining with wet pan mill + shaking tables

This setup is for rock gold ore,the final size needed to release the gold is 0-1mm.equipment list is as below:

1.hopper+vibration feeder: raw materials will feed into the hopper by truck or excavator as you want,then the materials will feeded into the jaw crusher by the vibration feeder automatically.

2.jaw crusher: jaw crusher is uesd to crush the rock gold ore, different model of the jaw crusher is with different input size,discharge size and capacity.the model of the jaw crusher is chosed based on the ore size and the capacity you want to process,big ore size need big model and more cost.

3.belt conveyor: belt conveyor is used transport the discharge from the jaw crusher to the hopper,it works automatically,will save much manual work.and the length and width can be customized as you requested.

4.hopper+trough feeder: there are two functions of the hopper and trough feeder

a.make the feeding work to each machine more smoothly.when you feed the materials to the jaw crusher,it will takes some time to get the discharge,the machines behind the jaw crusher will work for nothing at that time,means waste power and release the capacity of the machines behind the jaw crusher.if you add the hopper and trough feeder, each machine can runs better.

b.used to stock the discharge from the jaw crusher.sometimes the ore size maybe big, you need to use a big jaw crusher with big capacity.but you just want to start with a small capacity,then you can add the hopper and trough feeder to stock the discharge from the jaw crusher, and you can chose the hammer crusher with a small capacity behind the jaw crusher,no need to match the capacity with the jaw crusher.when the hopper is full, you can stop the jaw crusher.will save more power.

5.belt conveyor:belt conveyor is used transport the discharge from the hopper to the hammer crusher,it works automatically,will save much manual work.and the length and width can be customized as you requested.

6.hammer crusher: hammer crusher is used to small the discharge from the jaw crusher, because the feeding size of the wet pan mill is 0-25mm.the discharge from the jaw crusher hard to meet the needs of the wet pan mill. the hammer crusher can do work successfully, there is a sieve under the hammer crusher and the sieve size can be customized as you want, minimum sieve size can be 2mm,the smaller size you feed into the wet pan mill, the more efficent work you will get.

7.wet pan mill: for the rock gold ore, sometimes the gold can be released under the size 0-2mm or 0-1mm or 0-200mesh.these output size will need different machines and also depends on the ore condition.if you need to grind the ore to 0-1mm, you may need the wet pan mill.

8.shaking table: the shaking table is used to get the gold concentrate from the raw materials.when you add the water and materials to the shaking table, the gold will be separated from other stones and minerals which the gravity is lower than the gold.

9.gold smelting furnace: the gold concentrate from the shaking table can be smelted to the gold bar by the gold smelting furnace.will easy to carry the gold and in case of missing.

Notes: the wet pan mill and shaking table will need water when works, you can also add water to the hammer crusher,in case blocking the sieve of the hammer crusher.the machines in the video are just for you reference, need to reconfirm based on the ore condition you provide.

And our JXSC Mine Machinery has rich experience for design, control, and optimization of such a complex process for nearly 3 decades, with our solution, high recovery, high profit and low cyanide concentrations can be achieved simultaneously.

Processing Flow Overview

https://www.youtube.com/watch?v=S8dfV0VHBVA