Kaolin Recycling Process

- Maximize kaolin grade and recovery

- Achieve the necessary high brightness standard for kaolin applications

- Optimize cost-performance of plant operations

Kaolin can be recycled by both dry- and wet-processed. The dry process is simpler and produces a lower quality product than the wet process. Dry-processed kaolin is used mainly in the rubber industry, and to a lesser extent, for paper filling and to produce fiberglass and sanitary ware.

Wet-processed kaolin is used extensively in the paper manufacturing industry.

In the dry process, the raw material is crushed to the desired size, dried in rotary dryers, pulverized, and air-floated to remove most of the coarse grit.

Wet processing of kaolin begins with blunging to produce a slurry, which then is fractionated into coarse and fine fractions using centrifuges, hydrocyclones, or hydro-separators.

Kaolin Processing & Recycling Plant

And our JXSC Mine Machinery has rich experience for design, control, and optimization of such a complex process for nearly 2 decades, with our solution, high recovery, high profit and low cyanide concentrations can be achieved simultaneously.

Kaolin Recycling

Kaolin will produce a large number of tailings after ore dressing and recycling. As the recycling of kaolin tailings is less, with the continuous accumulation of tailings, it will encroach on a large amount of land, pollute water quality, and cause vegetation damage and soil erosion, and even cause Debris flow seriously affecting the ecological environment. Therefore, comprehensive utilization of kaolin tailings and recycling them can effectively prevent waste of resources and damage to the environment.

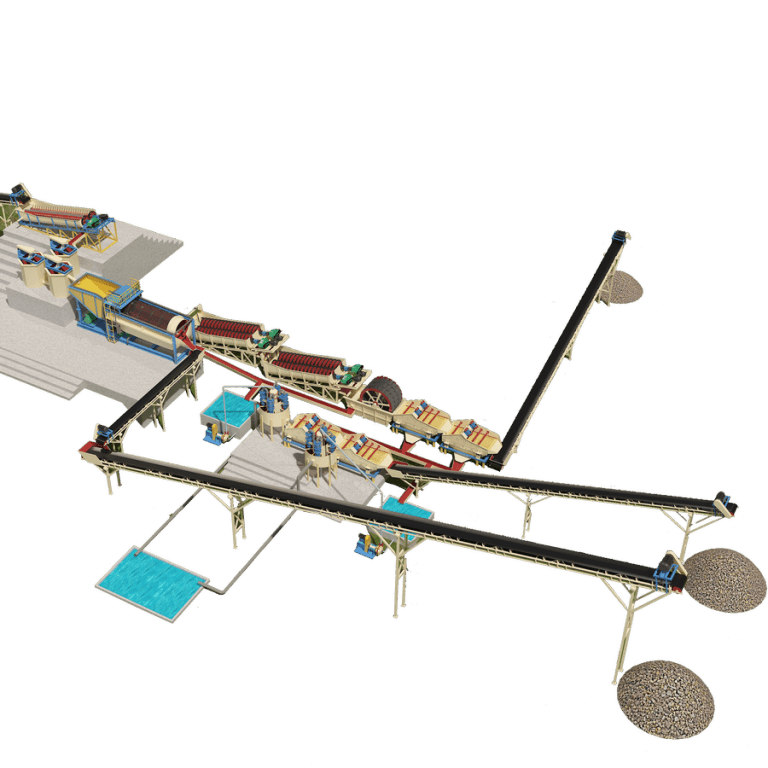

Kaolin ore processing plant designed by JXSC Mining Machinery

The Kaolin Ore processing plant with a capacity of 150 ton per day

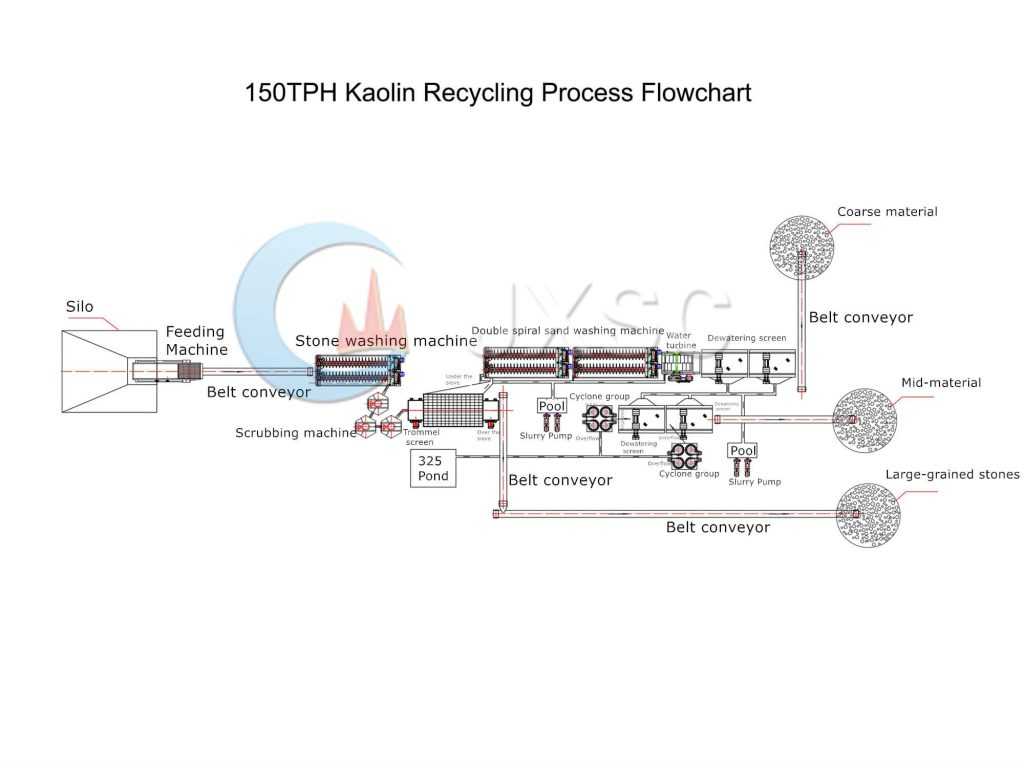

Processing Flow Overview

Detail Flowsheet for kaolin processing

Use a forklift or excavator to feed the raw materials to the hopper, and a feeder below the hopper will evenly feed the raw materials to the belt conveyor, and the belt conveyor will send the raw materials to the log washer. The function of the log washer is to disperse, stir and clean the agglomerated kaolin clay.

Enter the attrition scrubber for further cleaning. The function of the attrition scrubber is to better rub and fall off the sticky slime from the kaolin After washing by the attrition scrubber, then enter the trommel screen to screen out big waste stones which are sent to far place by belt conveyor, and the material under the screen enters the double spiral sand washer

The overflow of the first stage of the double spiral sand washing machine is kaolin concentrate, the underflow goes to the second stage of the spiral sand washer for again washing, the overflow of the second stage is kaolin concentrate, and the underflow goes to the wheel sand washer. The overflow from the wheel sand washer is the concentrate, the underflow goes to the dewatering screen. The under-screen materials of the first dewatering screen are the kaolin concentrate, the over screen materials go to the second dewatering screen for again dehydration, over screen materials of the second dewatering screen are coarse particles waste. , Use a belt conveyor to send away, under the sieve is the concentrate.

Kaolin Concentrate under the screen of two dewatering screens into 2# pond. Kaolin Concentrate from the overflows of the two spiral sand washers and wheel sand washer is into 1# pool. Use slurry pump to send 1# pond concentrate into 1# cyclone group, and the overflow of the cyclone group is kaolin concentrate, underflow flows to the dewatering screen for dehydration. and under the screen of the dewatering screen is a concentrate which goes into 2# pond. Over screen, materials are medium particles waste, which is transported away with a belt conveyor.

The under-screen concentrates of 4 dewatering screens are all in 2# pond, and they are pumped to 2# cyclone group with a slurry pump. The underflow of the 2# cyclone group goes to the dewatering screen, and the overflow is kaolin concentrate.

Finally, the overflow of the two cyclone groups (kaolin concentrate) will flow to the 325 concentrate pool.

Equipment Lists Used For Kaolin Recycling Processing

Trommel Screen

Spiral Washer

Vibrating Feeder

Dewatering Screen