quartz Processing

High-purity quartz is the raw material of high-end quartz products and the material basis of high-end products in the silicon industry. It is widely used in photovoltaics, electronic information, optical communications and electric light sources. It has an important position and role in strategic emerging industries of new materials and new energy.

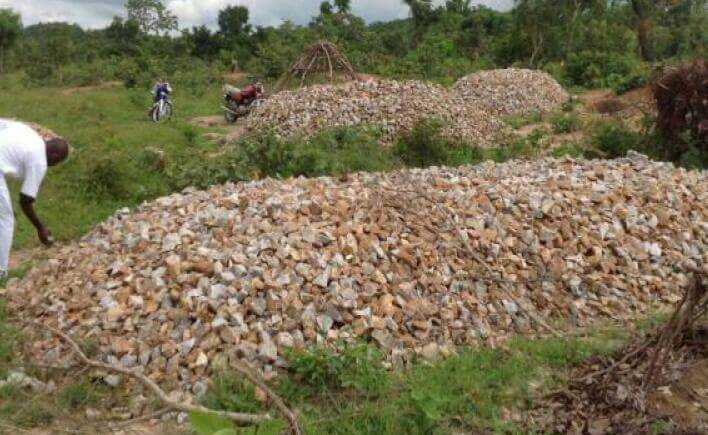

Quartz raw material

There are only a few raw ores in the world that can produce high-purity quartz sand for high-tech industries. There are many types of silica resources and large storage capacity. Quartzite, quartz sandstone and vein quartz are the main raw materials for producing high-purity quartz sand.

(1) Quartzite

Quartzite is a metamorphic rock dominated by quartz. It is formed by the metamorphism of quartz sandstone and siliceous rock, where the silica content is above 85%.

(2) Quartz sandstone

Quartz sandstone is a sedimentary rock formed by cementing quartz particles, and its silica content is as high as 95%.

(3) Vein quartz

Vein quartz is formed by filling silicon thermal fluid secreted by underground magma into rock fissures, and its silica content is as high as 99%.

Physical Quartz processing

1. Washing-classifying-desilting

In the quartz sand beneficiation process, the fine-grained grade with a particle size of less than 0.1 mm is usually called slime. For quartz sand with a large amount of clay and ore mud, as the particle size becomes finer, the grade of silica gradually decreases, while impurities such as iron and aluminum rise instead. Using water washing-classifying-desilting method can effectively improve quartz grade.

2. Scrub

For the thin film iron and adhesion impurities on the surface of quartz sand, the effect of water washing-grading desilting is poor. This requires the removal of the thin film iron and adhesion impurities suitable for the sand surface by means of mechanical force and the abrasive force between the sand particles. After the grading desilting, a better impurity removal effect can be achieved.

3. Gravity separation

gravity separation is to screen minerals according to their different gravity. Due to the difference in density, the mineral particles are affected by the fluid force and mechanical force in the medium, resulting in loose stratification, so that the ore particles are separated.

4. Magnetic separation

Magnetic separation is to separate the magnetic impurity minerals and particles in the quartz sand. The quartz in the quartz sand is a diamagnetic substance, which cannot be magnetized in the magnetic field, and most of the impurities containing Fe and Ti are paramagnetic substances, which can be magnetized, so that the impurities containing Fe and Ti can be removed by magnetic separation High quartz sand content.

5. Flotation

Flotation is the process of separating mineral particles by different physical and chemical properties on the surface of the mineral particles. The main function is to remove the related mineral mica and feldspar from the quartz sand.

The physical beneficiation method can only remove the impurities of mineral structure, and rarely remove the impurities on the surface of quartz sand. The purer the quartz sand, the higher the use value, so it is necessary to further purify the quartz sand after flotation.

chemical quartz processing

The chemical methods for purifying quartz sand are mainly acid leaching or alkali leaching. Compared with physical methods, the cost of chemical methods is higher, but the purification effect is better, especially when the purity of quartz sand is high, chemical purification is more effective.

The acids commonly used in acid leaching are sulfuric acid, hydrochloric acid, nitric acid, hydrofluoric acid, etc. Dilute acid has a good effect of removing impurities such as iron, aluminum, and magnesium, while concentrated sulfuric acid and hydrofluoric acid have a good effect of removing impurities of titanium and chromium. Therefore, in the actual beneficiation, mixing acid to purify quartz sand is the best.

Compared with general mineral processing engineering, high-purity quartz sand processing technology has the following characteristics:

(1) The reagent purity is high. Acid leaching and water washing are important steps in the processing of high-purity quartz sand. Due to the high purity requirements of high-purity quartz and the low content of impurity elements, the purity of the reagents such as acid and water must meet the corresponding requirements, otherwise it is difficult to produce qualified products.

(2) The reagent has strong corrosion. Hot acid leaching plays a key role in the purification of high-purity quartz. An important chemical property of quartz is excellent acid corrosion resistance, while other metal impurity components in the ore are generally poor in acid corrosion resistance. Under certain temperature conditions, this effect is more obvious. The acid leaching process used in high-purity quartz processing uses this principle to achieve chemical purification.

(3) The material standards are strict. Practice has proved that in the purification of high-purity quartz, materials such as containers that come into contact with the raw materials have a significant impact on the quality of the sample. Strictly controlling the material standards of each processing link of high-purity quartz sand is the key to ensuring quality.