Silica Sand Recovery

- Recovery silica sand contains at least 95% SiO2 and less than 0.6% iron oxide, which meet the industry-standard requirements.

- Scrubbing and removing clay from silica sand rock.

- Separate the silica sand from other heavy materials.

- Washing and clean water-soluble clays, deleterious materials and get a cleaner and brightness silica sand product.

- Sizing and classification to get the particle size you want.

What is silica sand

Silica sand, also known as quartz sand, white sand, or industrial sand, is formed with two main elements: silica and oxygen. Specifically, silica sand is made up of silicon dioxide (SiO2).

The common usage of Silica Sand

- Industrial abrasives

- Glassmaking

- Filtration media

- Paints & coatings

- Ceramics

- Construction materials

- Golf courses & sports fields

Silica Sand Processing & Recycling Plant

And our JXSC Mine Machinery has rich experience for design, control, and optimization of such a complex process for nearly 2 decades, with our solution, high recovery, high profit and low cyanide concentrations can be achieved simultaneously.

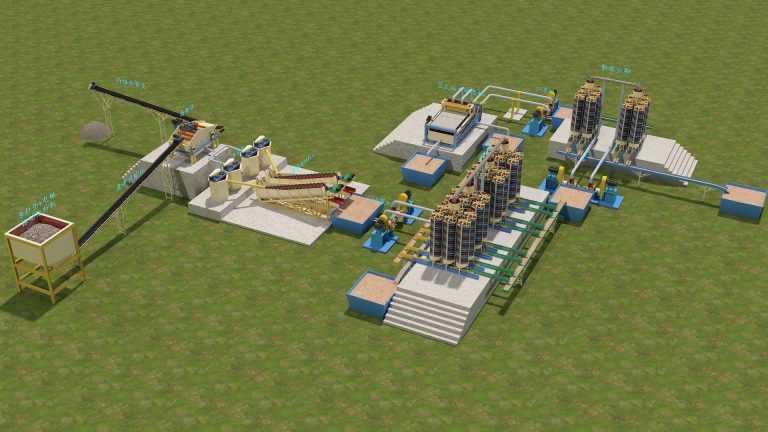

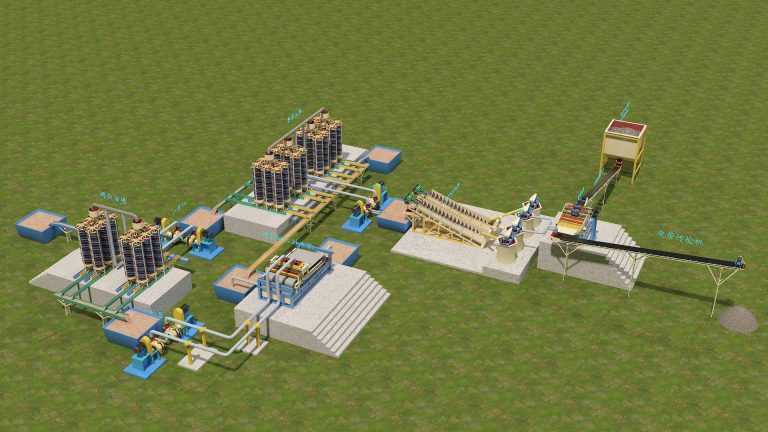

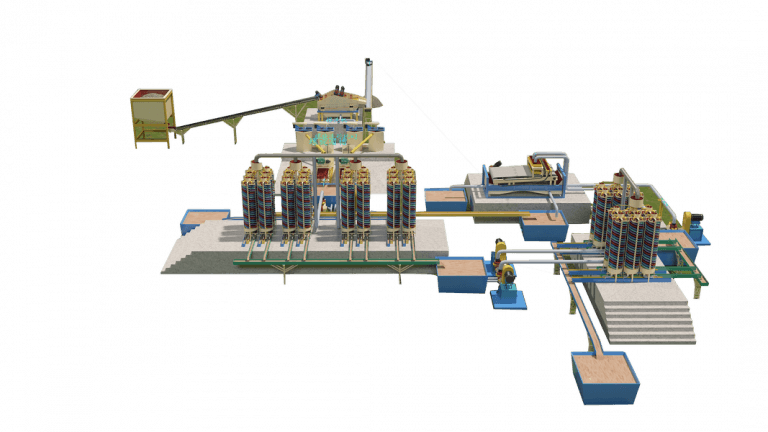

Silica Sand processing plant designed by JXSC Mining Machinery

This silica sand recovery processing plant is designed with a capacity of 100 TPH

Processing Flow Overview

https://www.youtube.com/watch?v=5yLUW2-mc7A

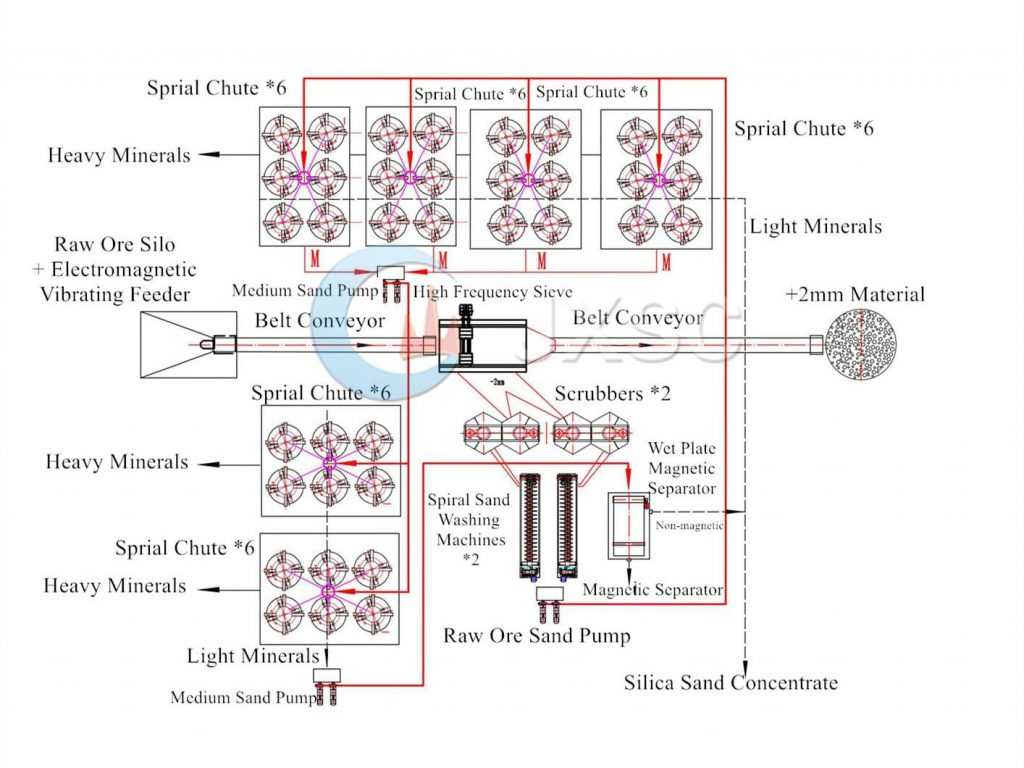

Detail Flowsheet for silica sand recovery processing plant

This flowsheet setup is for the silica sand washing, sizing, recovery process, the size range of the silica sand is 0-2mm.

The Detailed Flowchart Explanation

The raw bin+electromagnetic feeder for feeding materials to the high-frequency vibration screen automatically, you only need to load the materials to the raw bin by truck or excavator or else as you want.

The high-frequency vibration screen is for separating the silica sand size 0-2mm to the attrition scrubber washer, +2mm will be the waste sand and move away by the belt conveyor.

The attrition scrubber washer is for washing the much sticky clay, then to the spiral wash machine wash again to make sure the materials are cleaner.

The slurry pump transports the clean materials to the spiral chute to separate the silica sand from other heavy materials.

The wet plate magnetic separator is for separating the magnetic minerals in the silica sand, making the silica sand more purity.

The capacity for this washing plant can be customized as per request such as 10tph, 50tph,100tph, etc.,

Notes: If the materials are not much sticky, will not need the attrition scrubber washer or spiral wash machine, and the quantity of the machines just for your reference, will depend on your capacity.

The spiral chute will normally make two phases, the concentrate from the first phase spiral chute will to the second phase to concentrate again, that will make sure a higher grade and also release the workload of the magnetic separator.