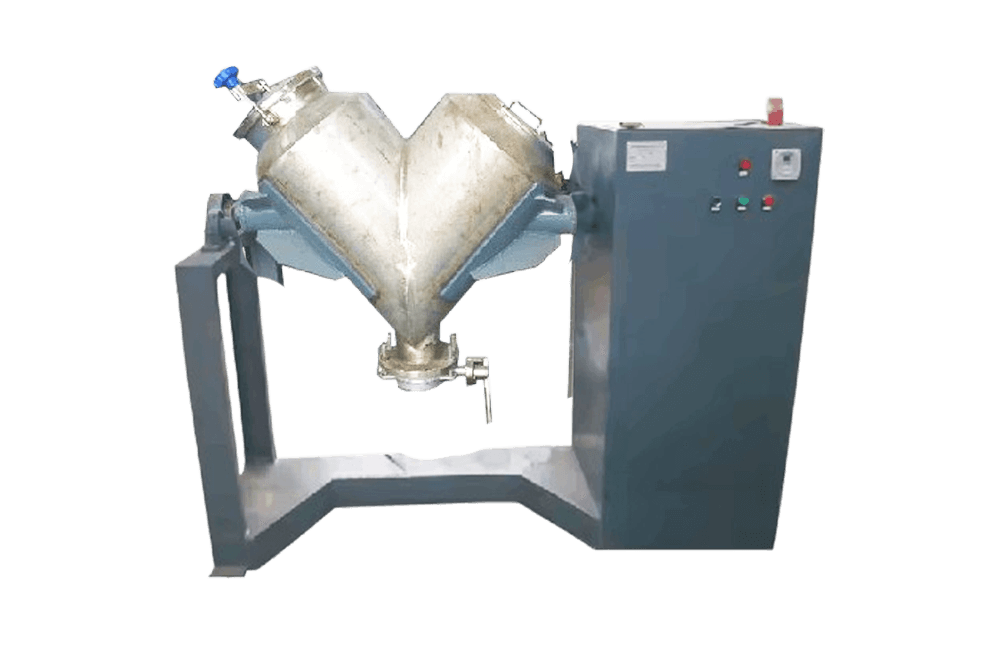

V-type Mercury Amalgamating Machine

Application: V-type mercury amalgamating machine is widely used in mineral extraction and smelting industries, such as amalgam purification equipment for gravity separation gold concentrate, and can also be used as refining equipment in the extraction process of precious metal ores such as silver and platinum.

Products display

Introduction of V-type Mercury Amalgamating Machine

This V-type mercury amalgamating machine, V-type gold amalgamator or amalgam mixer is a special and efficient gold refining equipment. It is a new design with good effect. It is especially suitable for granular or powdered materials with good fluidity. The mixing degree can reach 97%-98%. It is used to mix mercury and gold concentrate to obtain gold amalgam. Then the gold amalgam is distilled in a mercury distiller and pure gold is obtained. It is commonly used in equipment in the mining, metallurgy and chemical industries, especially in the gold ore refining process, to help mix mercury and ore pulp to improve the adsorption efficiency of mercury and achieve the purpose of metal or ore separation. The V-type gold amalgamator uses stainless steel inner and outer tanks with polished sides for easy cleaning. It is an alternative to the cylinder type amalgamator.

Working principle Of V-type Mercury Amalgamating Machine

By effectively mixing mercury with metals in the ore, mercury can absorb and concentrate metals, and then separate metals from mercury.

When the mixing barrel rotates, the materials in it are decomposed and combined. Since the inner wall of the V-shaped barrel is a very complex curved surface, the rotation trajectory of the logistics is irregular. In addition, the longitudinal flow generated by the material when it runs in the barrel is complex. This complex vertical and horizontal cross-flow flow enables the material to obtain a full mixing effect.

why choose JXSC V-type Mercury Amalgamating Machine

features & Advantages

1. The equipment has a new structure, low energy consumption, uniform mixing, good mixing effect, and fast speed;

2. The stainless steel design is more wear-resistant, corrosion-resistant and has a long service life;

3. The machine is driven by a motor instead of manual operation, which is stable and convenient to operate;

4. It has the characteristics of no dead corners in the barrel, no material accumulation, fast speed, short mixing time, and easy cleaning;

5. The stainless steel butterfly valve is used to discharge the material, and there is no dust leakage.

models & specifications

Model | (KW) | Volume (L) | Effective Volume (L) |

V-50L | 2.2 | 50 | 20 |

V-100L | 3 | 100 | 40 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.