Roller Crusher

Capacity: 1.5-70t/h

Feeding size: <50mm

Application: Roller crusher is widely used in crushing limestone, river pebbles, coal, granite, weathered rock, basalt, quartz stone, cement clinker, coal gangue, gold, quartz sand, feldspar, iron ore, manganese ore, limestone, dolomite, gypsum, talcetc.

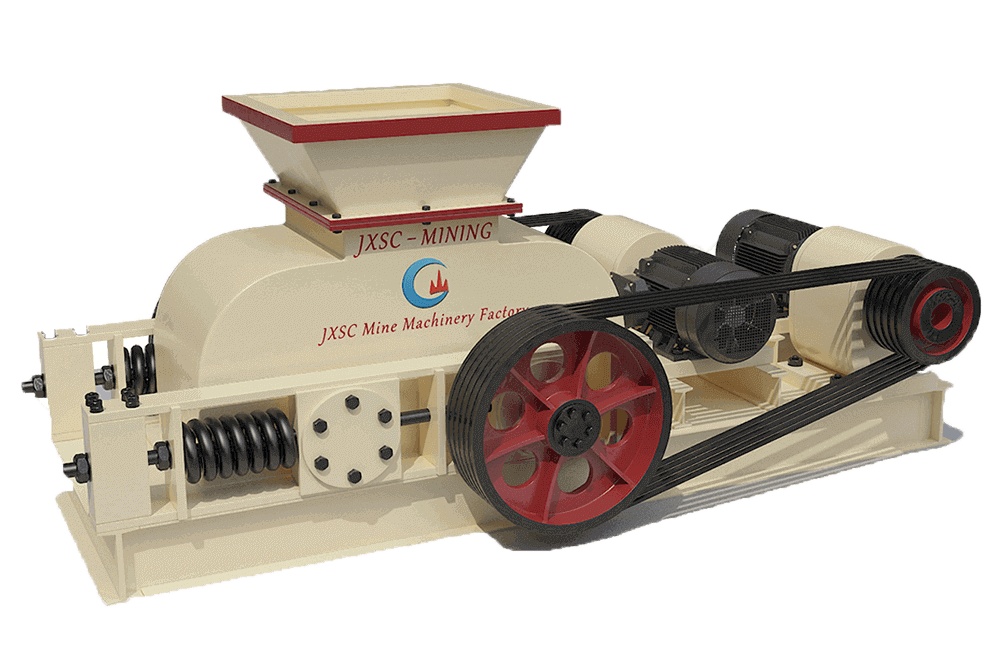

products display

introduction of roller crusher

Roller crusher, or double roll crusher is suitable for coarse and intermediate crushing of brittle and massive materials in industries such as cement, chemical industry, electric power, mining, metallurgy, building materials, refractory materials, coal mines, etc. The granularity is adjustable, which can crush the material with vertical compression strength ≤160MPa.

Especially in the coal industry, using this roll crushing machine to crush raw coal, it can be directly crushed only after removing iron, and impurities and without gangue. The crushed materials have an average particle size and a low over-crushing rate, simplifying the coal preparation process. Reduced investment and production costs. It is one of the most popular crushing equipment in mining, sand and gravel aggregate, and mineral processing industries. The double-roll crusher uses the extrusion crushing principle to achieve precise particle size, low consumption, and wear resistance. It is an ideal equipment for fine crushing and particle shape optimization of medium-hard and brittle materials.

working principle of double roller crusher

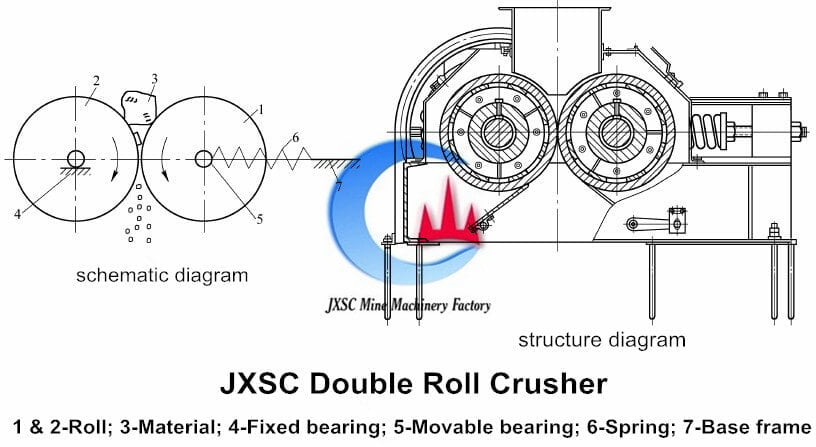

When the two-roller crusher works, the two rollers rotate towards each other, and the material entering the crushing roller is affected by the friction between it and the roller. As the rollers continue to rotate, the material is brought into the crushing cavity formed by the two rollers In the process, the material is crushed by being pressed, and then discharged from the lower part of the crushing roller. The width of the discharge opening of the crusher is determined by the minimum gap between the two rollers, and the width of the discharge opening determines the maximum particle size of the crushed product.

why choose JXSC roller crusher

Features & advantages of roller crusher

1. Uniform and controllable particle size: precise control of the discharge size by adjusting the roller spacing (manual or hydraulic)

2. Strong wear resistance: The roller surface can be welded with a wear-resistant layer or the tooth plate can be replaced, which has a long service life (especially suitable for crushing high-hardness materials).

3. Energy saving and environmental protection: the unit energy consumption is lower than that of impact crusher, with less noise and dust.

4. Efficient sand making: suitable for machine-made sand production, the finished product particles are fine and uniform.

5. Low powder rate crushing: The special design of the roller surface can reduce over-crushing, which is suitable for industries such as coal and chemical industry that need to control the amount of powder.

models & specifications

|

Rotor size |

Feed size(mm) |

Discharge opening range(mm) |

Capacity |

Motor Power |

Overall dimension(mm) |

|

φ400*250 |

<25 |

1-20 |

1.5-10 |

5.5*2 |

3080*1260*780 |

|

φ600*400 |

<35 |

1-20 |

5-20 |

15*2 |

3650*1540*960 |

|

φ800*600 |

<40 |

2-30 |

15-30 |

22*2 |

4250*2000*1200 |

|

φ800*700 |

<40 |

2-30 |

20-40 |

30*2 |

4250*2100*1250 |

|

φ1000*800 |

<50 |

2-40 |

35-70 |

45*2 |

4900*3250*1310 |

Name | Model | ||

2PGY-1000*800 | 2PGY-1200*1000 | 2PGY-1500*1000 | |

Grinding roller diameter | 1000mm | 1200mm | 1500mm |

Grinding roller length | 800mm | 1000mm | 1000mm |

Max feed size | <25mm | <30mm | <30mm |

Max throughput | <25mm 120t/h | <30mm 230t/h | <30mm 300t/h |

Discharge size | <5mm | <5mm | <5mm |

Final product capacity | 30-60t/h | 60-100t/h | 100-150t/h |

Power | 45KW-90KW*2 | 90KW-110KW*2 | 160KW*2 |

Total weight | 18000KG | 28000KG | 31000KG |

The pair of roller crushers are mainly composed of rollers, roller support bearings, pressing and adjusting devices, and driving devices. One roller bearing of the double roller crusher is fixed, and the other is that the roller bearing is movable.

★Crushing roller

As the main working mechanism of the crusher, the crushing roller is installed in parallel on the horizontal axis to make the opposite rotation movement. According to whether the bearing is movable, the crushing roller is divided into moving roller and static roller. The crushing roller mainly includes roller surface, wheel blade and shaft. The roller surface is made of three tapered arc irons and is fixed together with bolts and nuts. The roller shaft is fixed with the key and the wheel cone which is tapered on the surface. Due to the direct contact between the roller skin and the material, the roller skin often wears, so the roller surface often needs to be replaced.

★Transmission device

The transmission device is an intermediate device, which can transfer the power of the power device (motor) to the moving roller and the static roller, so that the moving roller and the static roller rotate relative to each other.

★Rack

The working environment of the roller crusher is harsh, so the frame must be firm and reliable. The frame material of the roller crusher is usually made of cast iron or steel, and it is manufactured by riveting or welding.

★ Adjustment device

The adjusting device is mainly used to adjust the size of the gap between the moving roller and the static roller, so as to control the granularity of the crushed product.

★ Overload protection device

The overload protection device is one of the important components of the roller crusher. At present, more overload protection devices use springs, and the state of the spring determines whether the crusher can operate normally.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.