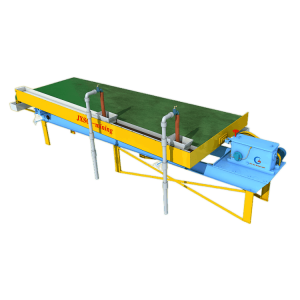

Mobile Jig Concentrator

| Capacity | 1-20 TPH |

| Application | A mobile jig with gold trommel plant for processing gold, diamonds, gemstones and other heavy mineral. The portable equipment can be used for sampling and production, with capabilities of up to 20 tph. |

Products display

overview

2. Applicable processing materials

3. Features Of Mobile jig plant

- Highly efficient processing – The mobile jig plants have many advantages, such as high recovery rate, large capacity, low water consumption, simple operation and high safety.

- Low water and electricity requirements – Compared with other recovery systems, the portable jig plant can be operated with less water. It can run efficiently when the pulp density is up to 40% (weight). In contrast, the mortar/shoal system works best in the 10% solids content range.

- Fine gold recovery system – Mounted small trommel screen or trommel scrubber for one-stop ore (gold, diamond) washing and separation plant.

- Portability – The jig concentrator is equipped with wheels for more convenient deployment; fixed type also supports custom.

Mobile Jig Concentrator Plant

JXSC provides two types of mobile jig concentrator plants – mobile machine to process gold and diamond:

- If raw ore contains sticky clay, better to use the trommel scrubber washing plant.

- If raw ore doesn’t contain sticky clay, the trommel screen washing plant would be a better choice.

Mobile Jig Plant with trommel screen

Equipment: mobile trommel screen + jig concentrator’ washing plant (stationary & movable type available; customizable)

Capacity: 1-20TPH

Application: it widely for washing raw ores without sticky clay; it is very popular in small-scale gold, diamond, coltan processing plants.

Function & Feature: The trommel screen sieves out a big waste stone first, and then the under-sieve material goes to a jig concentrator for gravity separation. Heavy minerals (concentrate) would be collected at the final.

Portable jig Plant with rotary scrubber

Equipment: portable trommel scrubber + jig concentrator’ washing plant (customizable)

Capacity: 1-20TPH

Application: It widely for washing raw ores contain sticky clay; it is very popular in those small scale gold, diamond, coltan processing plants.

Function & Feature: Trommel scrubber wash away stick clay and sieve material effectively, those under-sieve material goes to jig concentrator for further concentration. You would collect all sizes of valuable mineral at the jig machine via adjusting the screen mesh, such 2-5mm, with the low lost rate.

Product Videos

Mobile jig with a trommel screen used in alluvial gold wash plant site

An overall look at JXSC Mine Machinery’s portable jig concentrator

models & specifications

| Model | Jig Area (M2) | Stroke (R/Min) | Feeding size (mm) | Hutch Water ( T/H) | Pressure Water (kg/cm2) | Capacity;(T/H) | Power;(KW) | Overall dimensions (mm) | Weight (T) |

| JT0.57-1 | 0.57 | 60-160 | <6 | 1-2 | ≥0.3 | 1-2.5 | 1.5 | 1560x820x1550 | 0.612 |

| JT1-1 | 1.04 | 60-160 | <10 | 2-3 | ≥0.3 | 4-10 | 2.2 | 1322x1190x1915 | 0.9 |

| JT2-2 | 2.28 | 60-160 | <10 | 2-4 | ≥0.3 | 8-15 | 3 | 3225x1550x2150 | 1.637 |

| JT4-2 | 4 | 50-125 | <10 | 4-8 | ≥0.1 | 8-16 | 7.5 | 4240x1990x2750 | 4.6 |

| JT4-2A | 4 | 50-125 | <10 | 4-8 | ≥0.1 | 8-16 | 8 | 4240x1990x2750 | 4.6 |

| JT5-2 | 4.86 | 80-120 | <10 | 4-10 | ≥0.1 | 10-20 | 7.5 | 3940x2006x2580 | 4.6 |

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.