Gold Mining Equipment

Mineral Processing » Equipment » Gold Mining Equipment

Gold mining equipment is vital in extracting and refining gold from ore. The main equipment usually includes crushers, grinder mills, gold washing machines, classifiers, gravity separators, flotation and magnetic separators, concentration, filtration, dryer, etc. These equipment play a key role in gold mining, extracting gold from ore, from crushing-beneficiation-melting it into gold nuggets or bars. To meet your special needs, we support custom complete equipment and beneficiation solutions as per alluvial/ rock gold-containing ore characteristics.

If you are looking for a reliable and efficient equipment supplier, JXSC has over 38 years of mining experience and is your best choice!

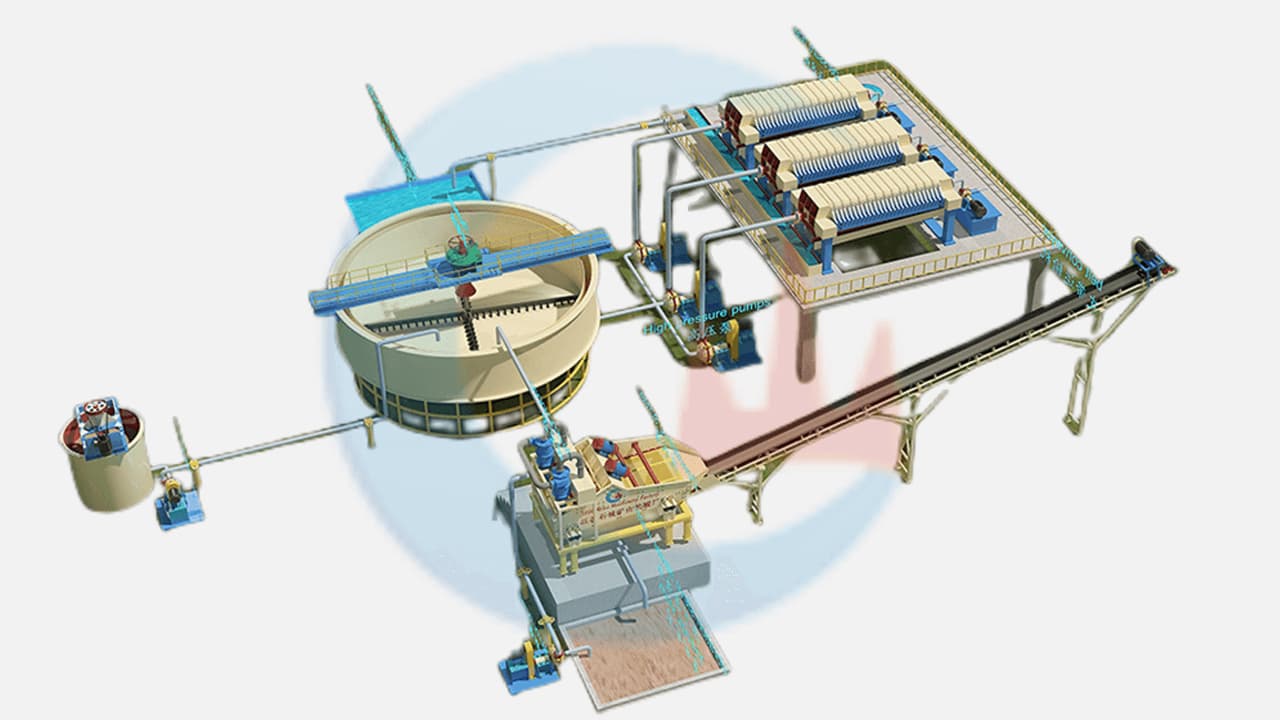

gold mining equipment for sale

Gold mining equipment typically includes equipment and tools used for gold extraction, refining and processing. The mined raw ore is put into the entire production line, and through the feeding, crushing, screening, grinding, gold recovery and other systems, the gold, heavy metals contained in the stone, sand, and mud are recovered. Such as flotation, gravity separation, magnetic separation, electric separation, CIP, leaching, etc. The finished product has high precision and purity using our gold mining/ processing/ melting equipment. Whether you need placer or rock gold mining equipment, JXSC provides you with customizable gold mineral processing solutions.

Rock Crusher

more >>

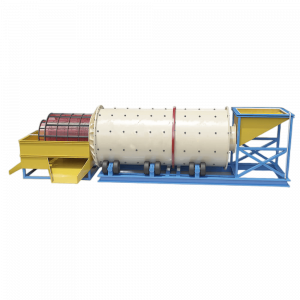

Grinding & Classification

more >>

gold mining process

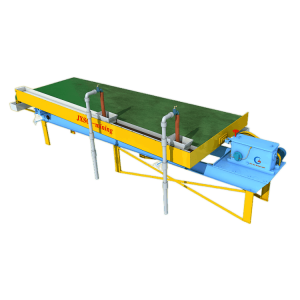

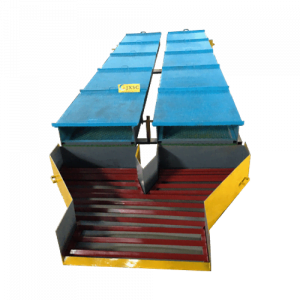

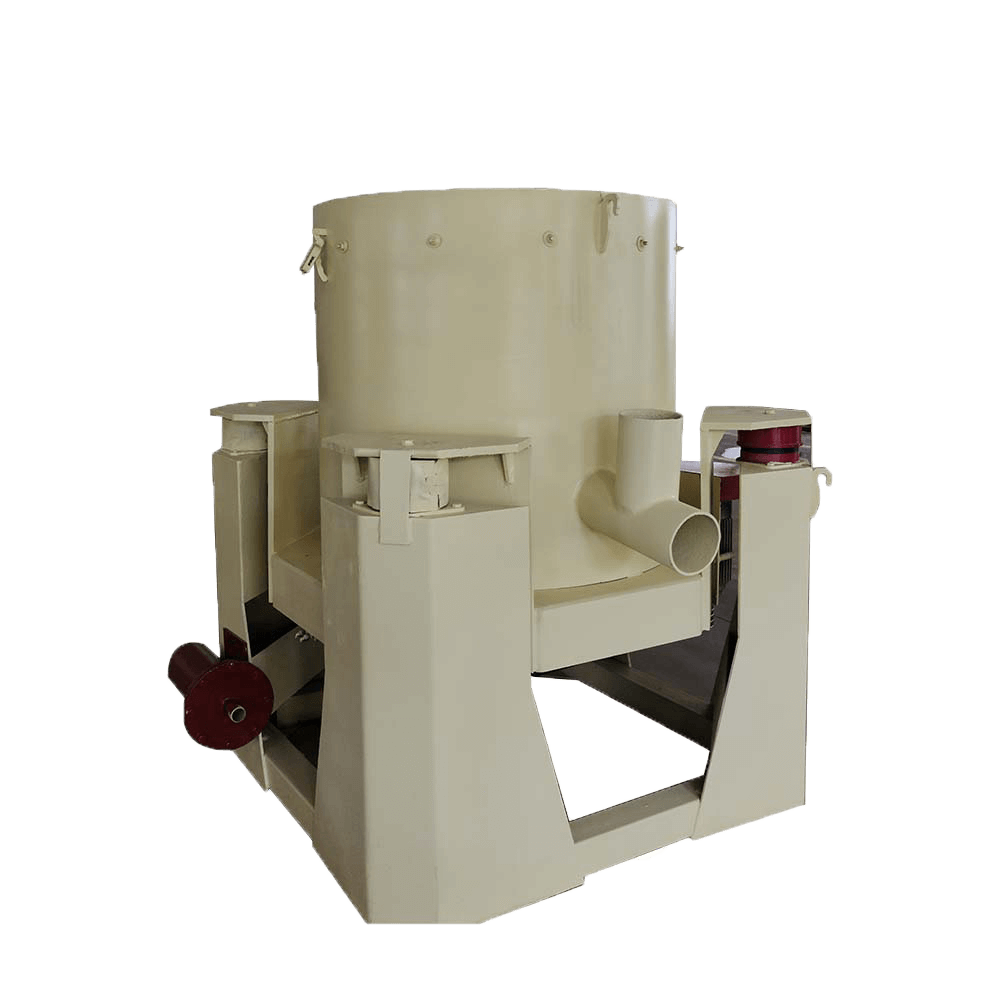

Gravity separation is the main method to recover gold placer ore, and gold and its associated minerals can be recovered to the greatest extent through gravity separation. Common equipment include gold trommel washer, jig separator, shaking table, spiral chute and centrifugal concentrator.

Hard rock gold mining process flow mainly includes crusher, ball mill, spiral classifier, separation equipment, etc. Its commonly used gold beneficiation processes are flotation, magnetic, electric and gravity separation combined mining process.

The flotation process is often used to beneficiate rock gold sulfide ores with high floatability. Gold can be enriched in sulfide minerals to a greater extent, tailings can be directly discarded, and the cost of mineral processing is low. The commonly used equipment is flotation machines and mixing tank.

Anon-filtered cyanide carbon pulp extraction process, its principle is to use activated carbon to directly absorb and recover gold from cyanide pulp. Mainly used for gold-bearing oxide ores with high slime content.

A process flow of adding activated carbon to pulp and simultaneously leaching and adsorbing gold is one of the main methods of gold beneficiation at present. It includes six stages of pulp removal, concentration before leaching, leaching and adsorption, desorption electrolysis, pyrometallurgy, and activated carbon regeneration.

Related Equipment

Why Choose JXSC Gold Mining Equipment

- Highly automated design

- High efficiency production

- Wide range of applications

- High strength and durability

- Controllable and flexible

- Low energy, Large capacity

- High-precision Separating

- Factory Price & Customizable

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.