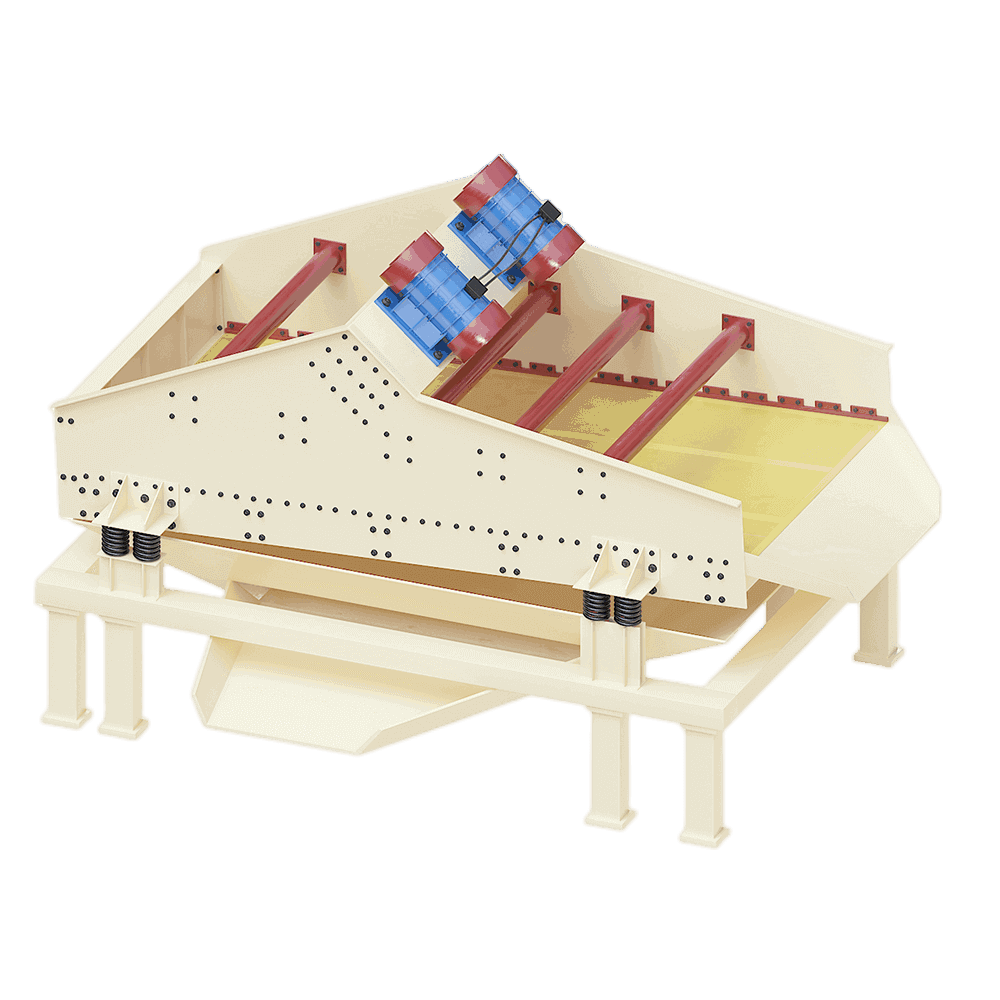

dewatering screen

| Capacity | Customizable, 5-250 tph |

| Screen Sieve | Material: PU, PE, and others materials Screen size: 1.6-10.8m³ |

| Advantages |

|

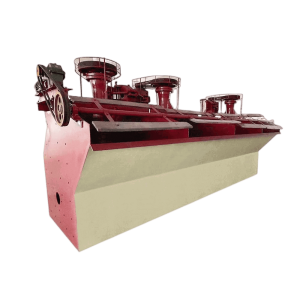

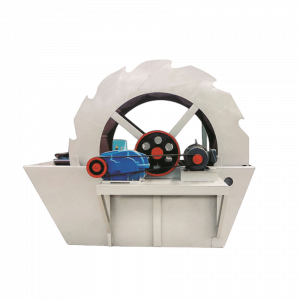

Products display

introduction of dewatering screen

The dewatering screen is also called “dewatering vibrating screen”, a common mining dewatering equipment. Also called sand and gravel dewatering screen, mining dewatering screen, coal slime dewatering screen, tailings dewatering screen, etc. The main function of the machine is dehydration, desliming, and demediation to solve the problem of water content of the material. It can also be equipped with sand washing machine, hydrocyclone and other machines to form an integrated fine sand recovery machine, which can wash, grade and dehydrate the material.

Application: It is mainly used for the dehydration of tailings in the mineral processing industry, coal slime dehydration of coal preparation plants, and dehydration of washed quartz sand and ceramic slurry; in mining and industrial industries, it is used for dry-wet classification, dehydration, disintermediation and desliming of medium and fine materials.

Working principle of dewatering screen

The machines adopt dual-motor self-synchronization technology, a general-purpose eccentric block, and an adjustable amplitude vibrator. The material with high water content is introduced into the basket or cylinder of the dewatering screen through the feed port. The material is moved at high speed by the centrifugal force of the on screen. Moisture is separated from solid materials to form two parts: water and solid materials. The separated water is discharged through the discharge port of the machine, while the solid materials continue to stay inside the machine. The separated solid material is collected through the equipment’s receiving port to complete dehydration.

why choose JXSC dewatering screen

features & Advantages of dewatering screen

1. The sieve holes are not easy to clog, the dehydration effect is good, the screening accuracy is high, and the processing capacity is large;

2. JXSC dewatering equipment can be used in sand washing, ore dressing plants, tailings dry discharge, etc., with a wide range of applications;

3. The screen is made of ultra-high molecular polyurethane material, which is resistant to impact, low temperature, wear and chemical corrosion, and has a long service life;

models & specifications

Model | Screen Size(m³) | Motor Power(kw) | Input Size(mm) | Capacity(t/h) |

DN0820 | 1.6 | 0.75*2 | <10 | 5-10 |

DN1020 | 2 | 1.1*2 | <10 | 10-20 |

DN1225 | 3 | 2.2*2 | <10 | 30-50 |

DM1530 | 4.5 | 3*2 | <10 | 50-70 |

DN1836 | 6.5 | 3.7*2 | <10 | 70-110 |

DN2040 | 8 | 5.5*2 | <10 | 120-160 |

DN2245 | 9.9 | 15*2 | <10 | 160-220 |

DN2445 | 10.8 | 18.5*2 | <10 | 220-250 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.