Gold CIL processing

CIL (Carbon In Leach), the gold carbon leaching method, is the carbon leaching method for gold extraction. Normally, the CIL process can concentrate gold from 2.5–3.5 g/t in ore to 2000 to 6000 g/t in carbon.

The CIL gold process is suitable for beneficiating oxidized gold ore with low sulfur and mud content; Or process the gold tailings after gravity separation and mercury mixing.

Gold CIL (Carbon in leach) Process

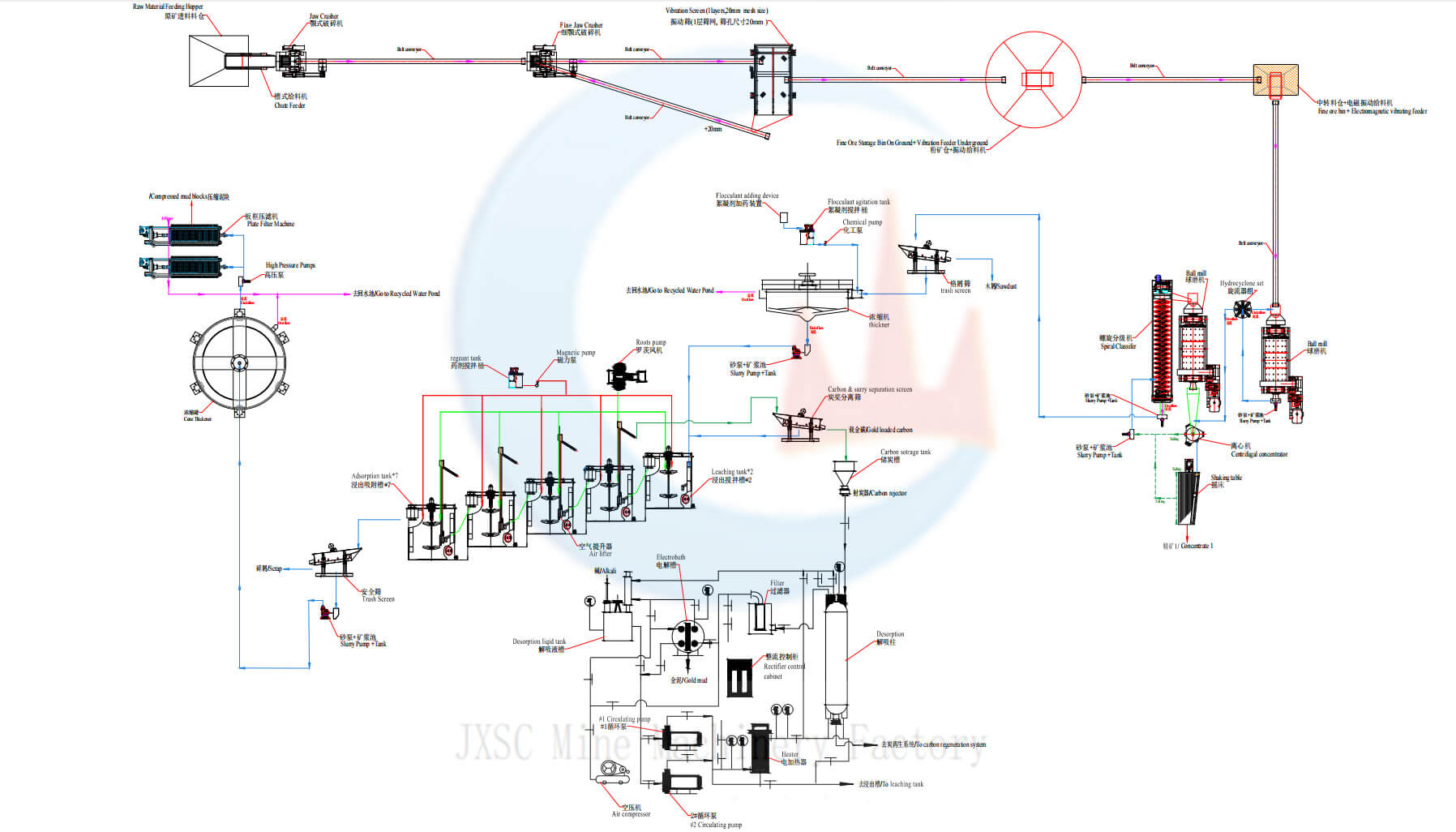

It is a process in which activated carbon is added to the pulp, and leaching and adsorption are carried out simultaneously. Simplifies leaching and cyanidation for the CIP process. The main gold CIL process flow: crushing, grinding, leaching, desorption electrolysis, tailings dewatering.

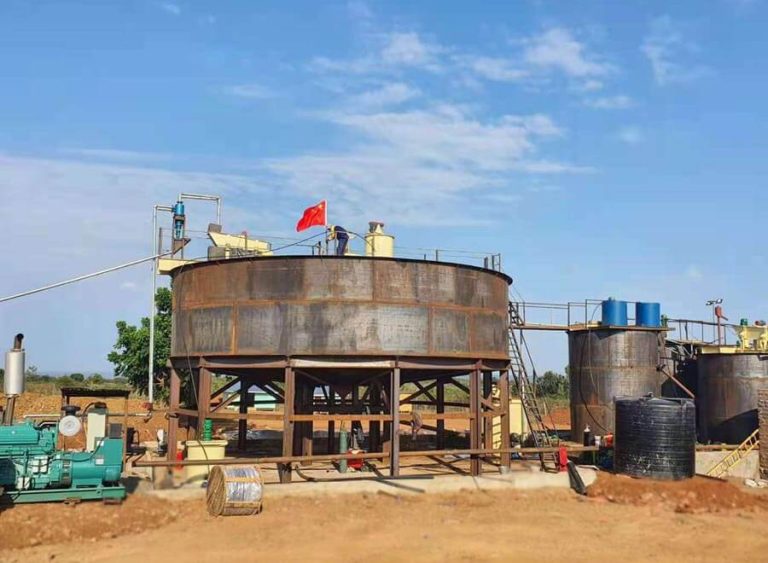

The CIL gold plant is complex as it involves the leaching and adsorption of competing species, the influence of cyanides, oxidizing agents and passivating agents and carbon attrition. However, we (JXSC) have over 38 years of experience in designing, controlling, and optimizing gold processing solutions for such a complex process. With our solution, high recovery, high profit and low cyanide concentrations can be achieved simultaneously.

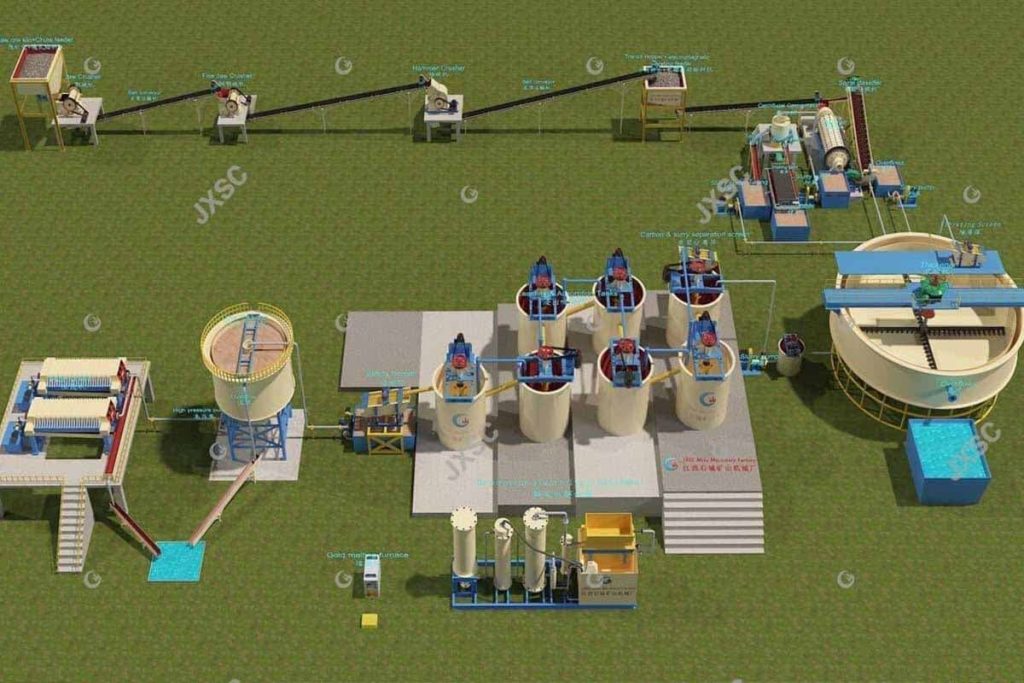

CIL Gold Processing Plant

Gold Carbon in leach plant

The CIL process mainly includes the preparation of leaching slurry, cyanide leaching, activated carbon adsorption, gold-loaded carbon desorption, obtaining gold mud through electrolysis, recycling of gold-depleted carbon, and processing of leaching slurry.

- First, the ore is crushed and ground into fine powder to obtain the optimal particle size for efficient gold recovery. The gold particles are then exposed to the leachate for maximum exposure.

- The concentration of the slurry will not only affect the leaching time, but also affect the suspended state of the activated carbon. Therefore, in order to achieve a suitable leaching concentration of the slurry, the slurry needs to be dehydrated through a thickener before leaching.

- Next, the slurry is mixed with cyanide and oxygen to initiate the leaching process, where the gold dissolves into the solution. Thicken before leaching, and add carbon soon after leaching starts so that leaching and adsorption can proceed simultaneously.

- Once the gold is leached from the ore, it is adsorbed onto activated carbon particles in large tanks. This adsorption step can effectively recover gold from solution.

- Subsequently, the loaded carbon passes through an elution loop where the gold is desorbed from the carbon for further processing and refining.

- The tailings slurry is pumped to the filter press, and the filter cake, which is the tailings, is transported out by the belt conveyor and then transported by truck to the stockyard for storage. The filtrate enters the circulating pool for reuse, which can save lime and sodium cyanide.

- The precious liquid obtained by desorption of gold-loaded carbon contains a higher concentration of gold and silver cyanide complex ions, while the impurity ions are greatly reduced, providing an ideal solution for the electrowinning method to reduce and recover gold from the precious liquid. Finally, after being processed by a desorption electrolysis system, the gold mud obtained can be smelted into gold ingots. High purity solid gold can be obtained.

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.