Sand Washing Machine

Capacity: 15-400 t/h

Types: Wheel or Spiral type

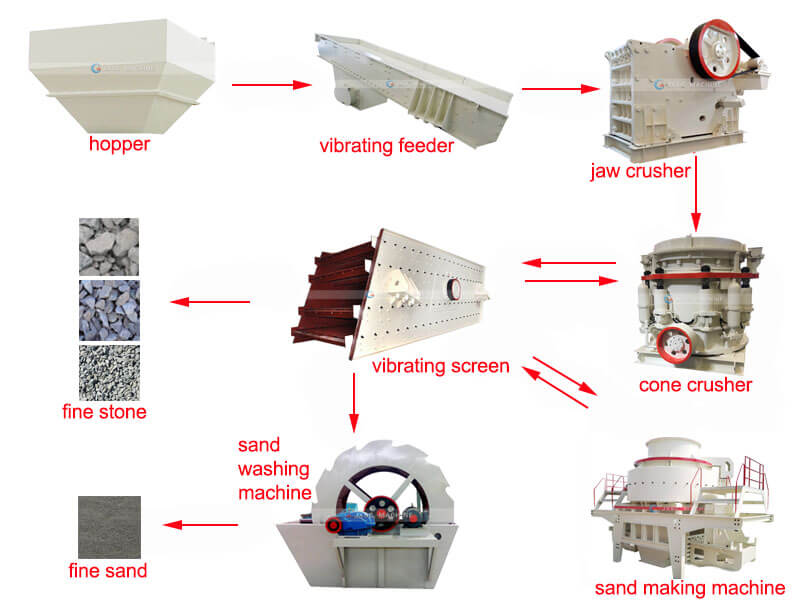

Application: Quartz sand, limestone, river pebbles, river sand, calcite, aluminum ore and other natural sand and machine-made sand washing; or widely uesd in sand making production line.

Products display

Introduction of Sand washing machine

Sand washing machine is widely used for washing materials in industries such as gravel yard, mining, building materials, transportation, chemical industry, water conservancy and hydropower, and concrete mixing station. Spiral sand washer and wheel sand washer are two common sand washing equipments, which can be used for washing, grading and dewatering, with high efficiency for sand washing and cleaning, and improve the quality of products.

sand washing machine for sale

types of sand washing machine

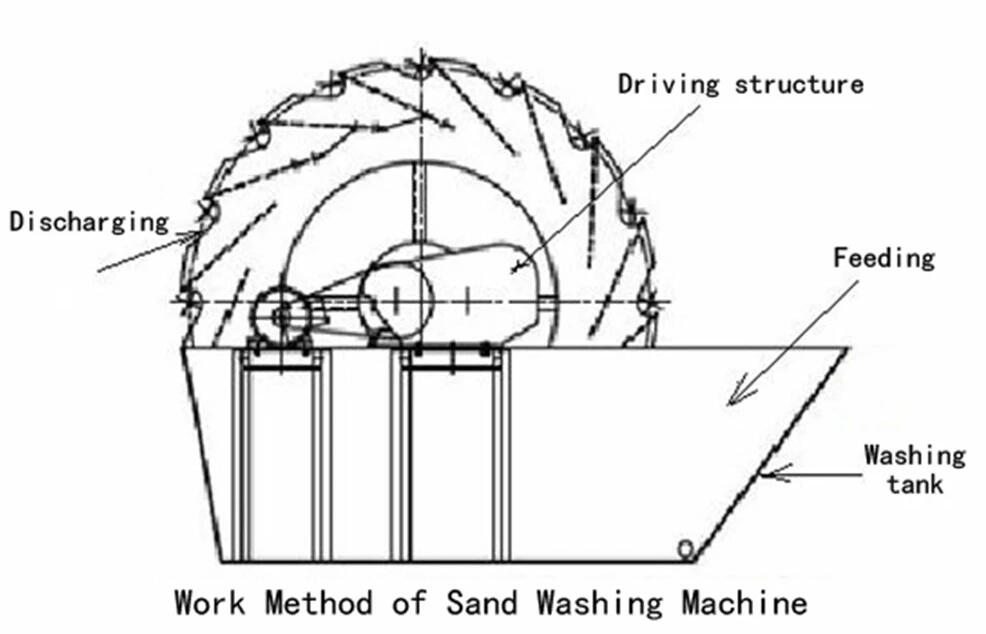

Capacity: 15-200 t/h

features of wheel type sand washing machine

- Its transmission part is especially separated from water and sand. Its failure rate is much lower.

- The loss of fine sand and stone powder is very small. After washing, the buildings’ sand gradation and fineness modulus have reached the standard requirements.

- Except for the screen, the bucket sand washer has almost no wearing parts, a long service life and less maintenance.

- Convenient maintenance, large processing capacity, low power consumption.

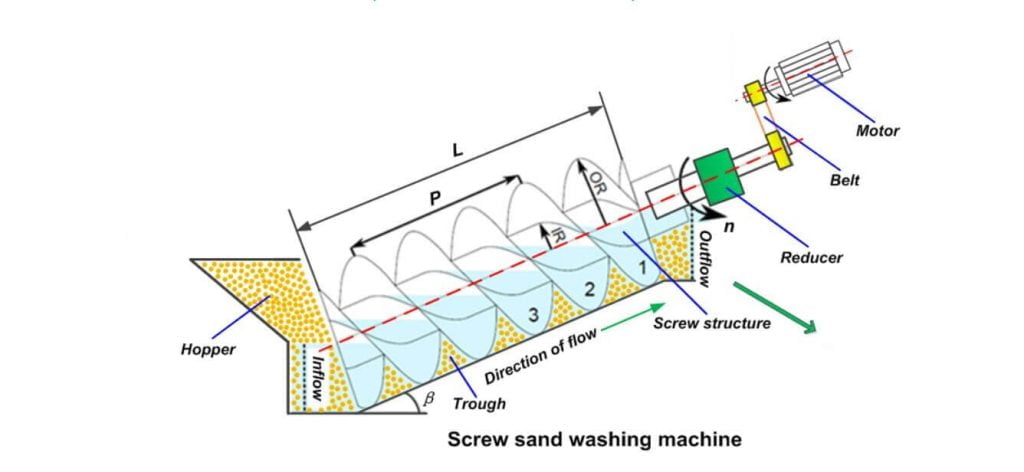

Capacity: 20-400 t/h

features of spiral type sand washing machine

1. Fully enclosed transmission device, adjustable weir plate, ensuring the equipment is efficient, durable, cleaning, good dehydration, and fine-grained products remain stable.

2. The bearing is separated from water and materials to avoid damage caused by premature contamination and rusting of the machine.

3. Suitable for various working environments, long service life, low maintenance cost and almost no wearing parts.

4. The loss of washed materials is low, and the efficiency of selective washing is high, which can fully meet the requirements of high-grade materials.

models & specifications

Model | Diameter of The Wheel Bucket | Speed of Rotation(r/min) | Maximum Feeding Size | Process Capacity |

| Overall Dimensions | Weight |

XS22-2 | 2200 | 2.5 | ≤10 | 15-30 | 4 | 3180*1955*2350 | 2260 |

XS26-2 | 2600 | 2.5 | ≤10 | 20-50 | 5.5 | 3515*2070*2672 | 2500 |

XS28-3 | 2800 | 1.2 | ≤10 | 50-80 | 11 | 3964*3014*2895 | 3200 |

XS28-4 | 2800 | 1.17 | ≤10 | 60-100 | 15 | 3964*2137*2895 | 3580 |

XS30-4 | 3000 | 1.2 | ≤10 | 70-110 | 15 | 4169*3456*3055 | 3850 |

XS32-3 | 3200 | 1 | ≤10 | 80-120 | 15 | 4340*2760*3349 | 3950 |

XS32-4 | 3200 | 1.17 | ≤10 | 95-130 | 18.5 | 4346*2198*3345 | 4185 |

XS36-5 | 3600 | 1 | ≤10 | 110-200 | 22 | 4580*3218*3600 | 4600 |

Model | Screw Dia. | Screw Number | Feeding Size | Capacity | Water Consumption(m3/h) | Motor Power | Overall Dimensions |

XL-750 | 750 | 1 | <10 | 20-40 | 9-60 | 7.5 | 7000×950×1330 |

2XL-750 | 750 | 2 | <10 | 50-70 | 18-120 | 2*7.5 | 7000×1750×1330 |

XL-1000 | 1000 | 1 | <10 | 50-80 | 10-70 | 11 | 8070×1200×1638 |

2XL-1000 | 1000 | 2 | <10 | 100-150 | 20-140 | 2*11 | 8070×2250×1638 |

XL-1200 | 1200 | 1 | <20 | 100-120 | 20-140 | 18.5 | 9070×1430×1900 |

2XL-1200 | 1200 | 2 | <20 | 150-180 | 40-280 | 2*18.5 | 9070×2700×1900 |

XL-1500 | 1500 | 1 | <20 | 150-200 | 60-300 | 22 | 10800×1720×1900 |

2XL-1500 | 1500 | 2 | <20 | 200-300 | 120-450 | 2*22 | 10800×3300×1900 |

XL-2000 | 2000 | 1 | <20 | 250-320 | 160-460 | 37 | 11000×2200×2100 |

XL-2400 | 2400 | 1 | <20 | 320-400 | 200-620 | 45 | 12500×2700×2200 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.