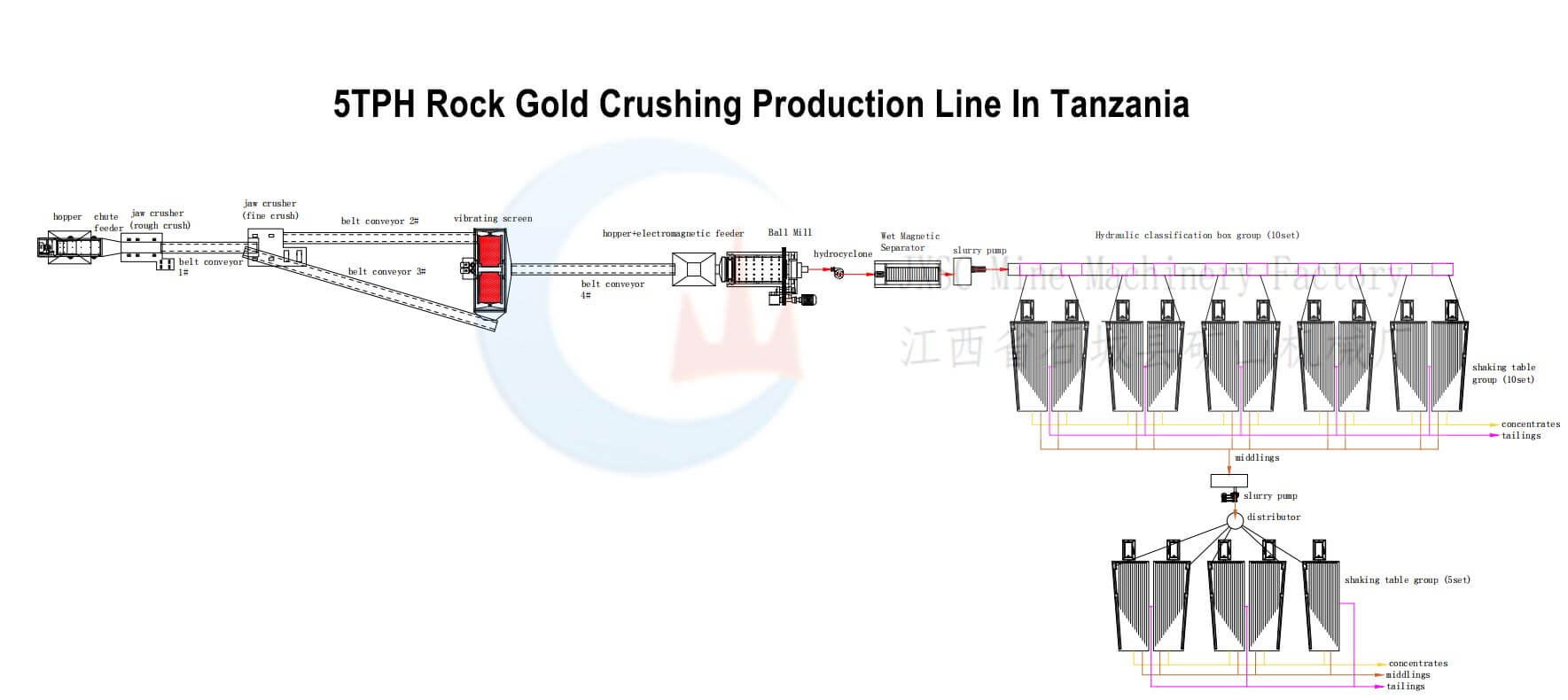

5TPH Rock Gold Crushing Production Line In Tanzania

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info.

1. Raw ore: rock gold ore

2. Capacity: 5TPH

3. Location: Tanzania

Process

Feeding – Crushing – Screening – Grinding & Classiying – Magnetic separation – Classification – Gravity separation

process flow

5TPH Rock Gold Crushing Production Line

JXSC provides Tanzanian customers with complete rock gold crushing production lines and equipment, including two stages crushing and shaking table gravity separation, and high-grade finished products.

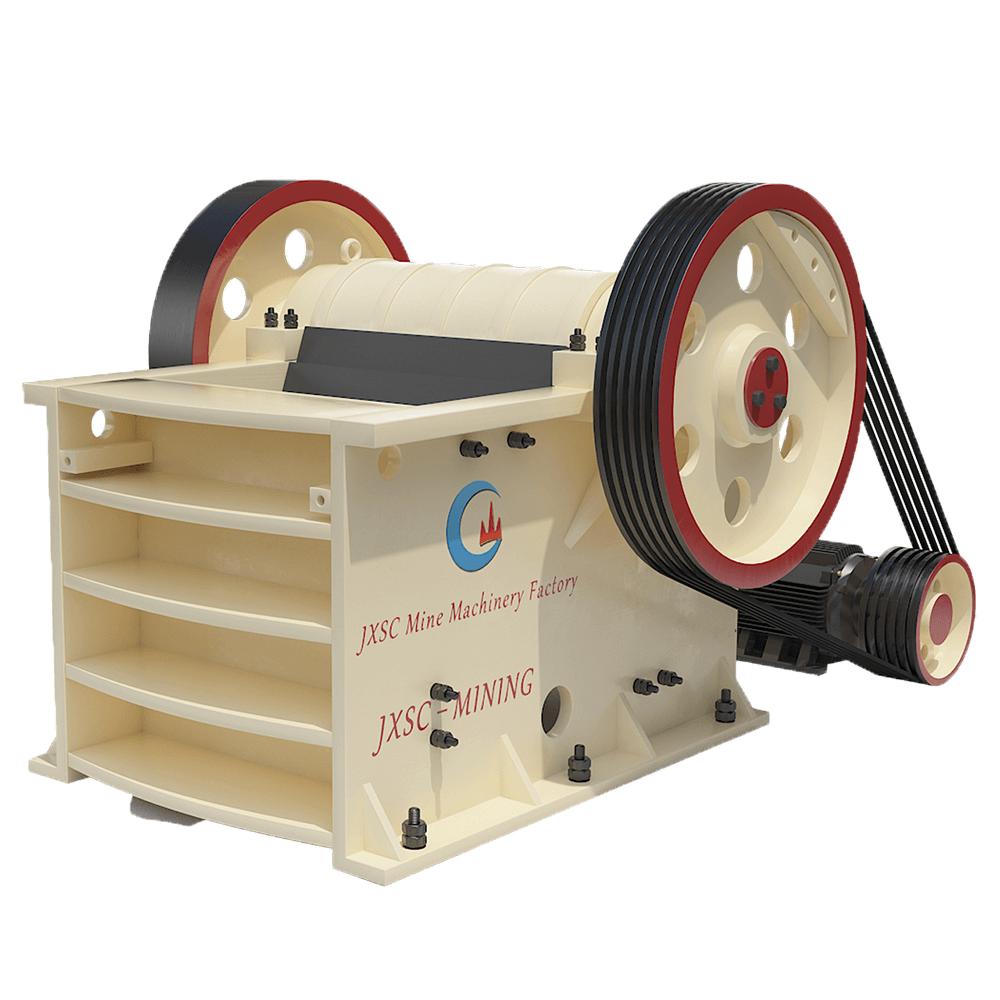

(1). Feeding, Crushing, Screening: chute feeder, jaw crusher, vibrating screen, electromagnetic vibrating feeder

The materials enter the trough feeder through the hopper, are directly fed to the coarse jaw crusher, and then transported to the fine jaw crusher through the belt conveyor for fine crushing. All materials are sent to the vibrating screen for classification, and materials that do not meet the size are returned to the fine jaw crusher for re-crushing. Finally, materials that meet the size enter the ball mill through the belt conveyor and electromagnetic vibrating feeder.

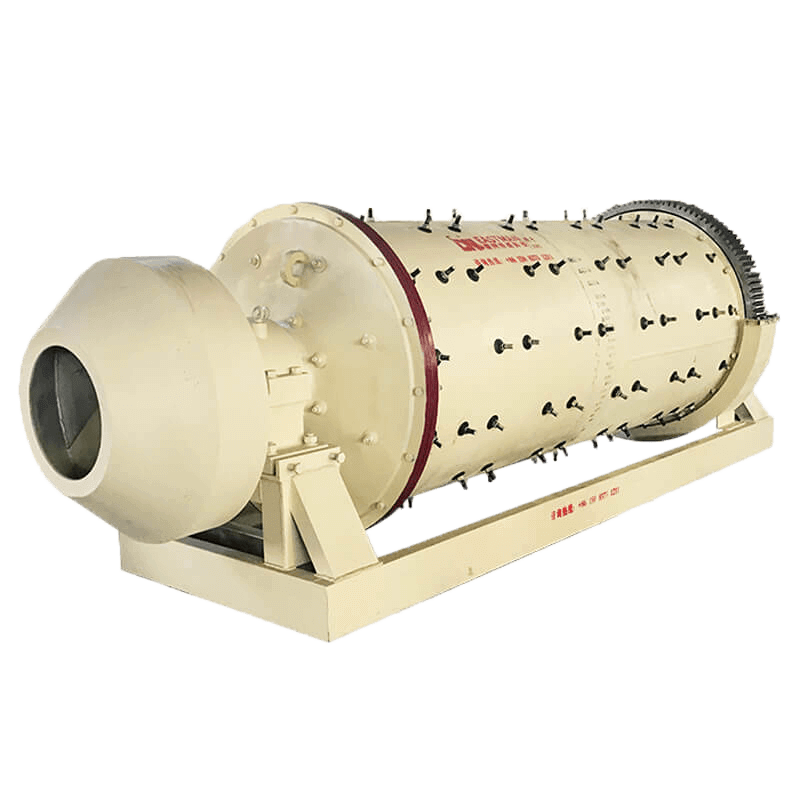

(2). Grinding, Classification, Magnetic separation: ball mill, hydrocyclone, wet magnetic separator

The ball mill grinds the materials into powder and then enters the hydrocyclone for classification. Hydrocyclones integrated into the grinding circuit effectively separate valuable products from waste materials, adapting them to further separation or recycling processes. The ore slurry enters a wet magnetic separator to remove iron impurities. The final material enters the hydraulic classification box using a slurry pump.

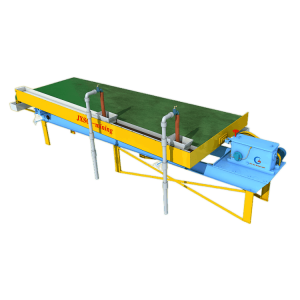

(3). Classification, Gravity separation: hydraulic classification box group (20mm drop between two classification boxes), 6-s shaking tables

In the hydraulic classification operation before shaking table separation, it plays the role of classifying and distributing the ore volume to improve the separation efficiency. The distributed slurry enters ten shakers respectively and can be obtained at one time: concentrate, middlings, and tailings. Among them, the middling ore slurry is pumped into the distributor to mix evenly, and then enters the second stage of five shaker tables for sorting. After two stages of shaking the table, the gold ore finished product is high purity.

Whether placer gold or rock gold ore processing, we support customized gold processing production lines and machines, contact us for designing flows based on your mine conditions or specific needs to maximize gold recovery rates.

Main Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, no investing)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.