Mineral Separation Equipment

JXSC provide mineral separation equipment including flotation machines, magnetic separators, electrostatic separators, etc. Among them, magnetic separators are diversified, mainly including wet drum, high-intensity, three-disc, flat plate, and high-gradient magnetic separators. It’s suitable for removing iron impurities and purifying various metal ores and non-metallic minerals, such as ilmenite, magnetite, chromite, rutile, hematite, coltan, feldspar, quartz sand, other mineral processing plant.

Mineral separation equipment for sale

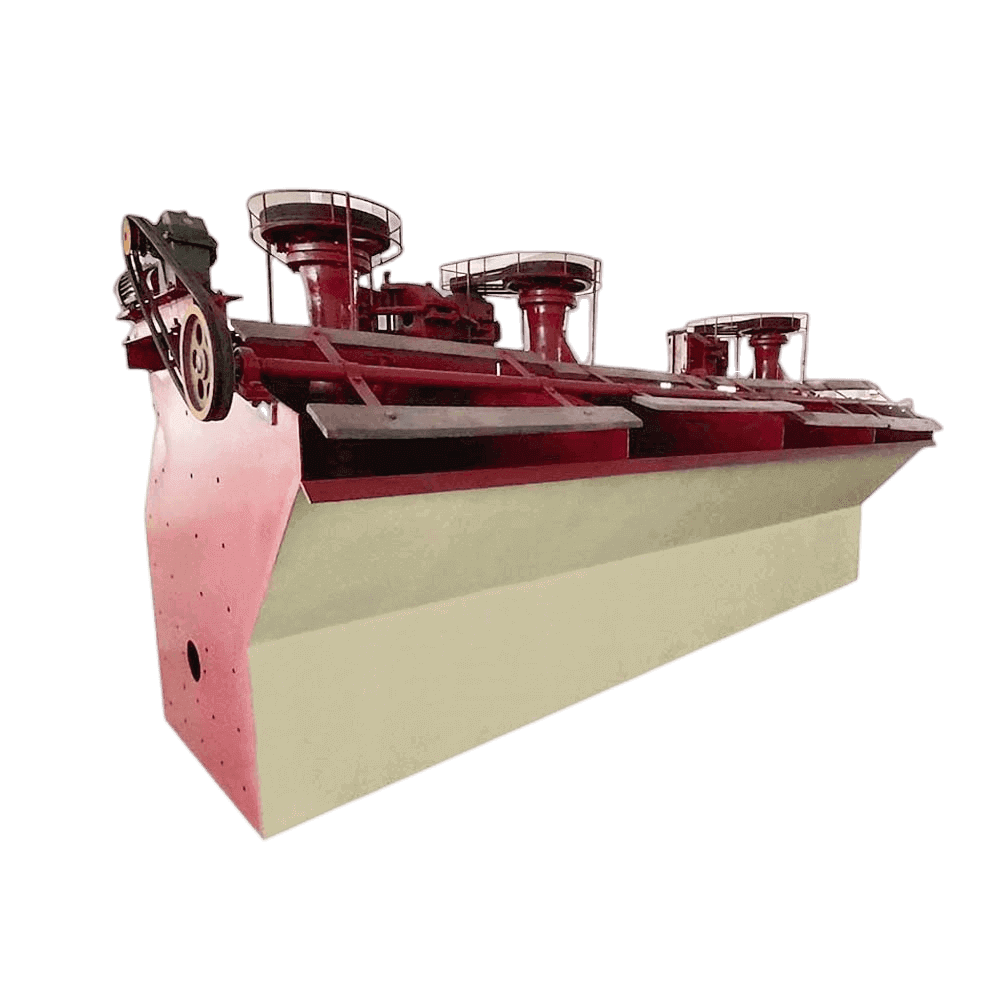

flotation machine

Capacity: 0.18-50m³/min per cell Application: Separating copper, gold, zinc, lead, nickel, fluorite, molybdenum ore, nickel ore, barite, antimony, feldspar, phosphate rock, lithium and other mineral processing plants.

wet drum magnetic separator

Capacity: 0.5-180 t/h

Application: Commonly used for wet magnetic separation of pyrite, magnetite, ilmenite, manganese, iron ore and other materials with particle size below 3mm.

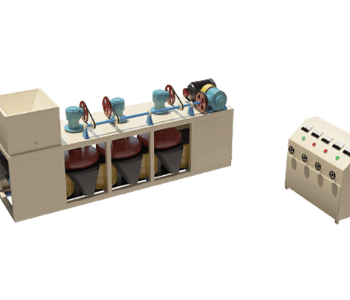

Three disc magnetic separator

Capacity: 100-800 Kg/h

Material Size: ≤2mm

Application: Suitable for dry separation of various metal minerals such as titanium ore, tungsten, tin ore...

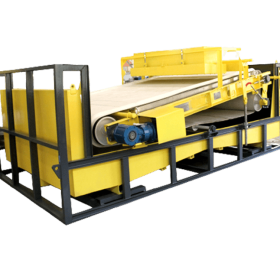

plate magnetic separator

Capacity: 8-35 t/h

Application: Mainly used for wet separation of various weakly magnetic metal minerals such as magnetite, hematite, ilmenite, tungsten ore, and iron removal process of silica sand and kaolin.

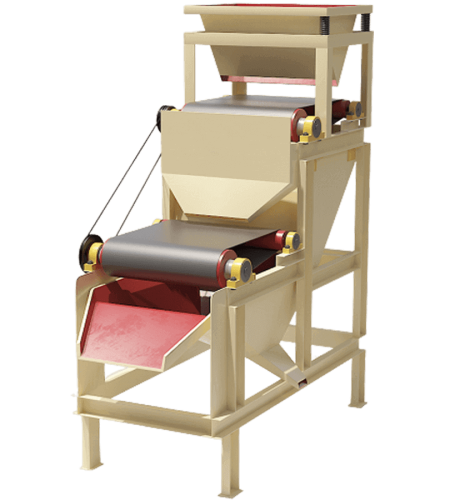

High Intensity Dry Magnetic Separator

Capacity: 0.2-9 t/h

Application: It is suitable for the separation of weakly magnetic minerals and non-magnetic minerals such as tantalum niobium, tin, manganese ore, chromium ore, rutile, zircon, beach sand, etc.

Electrostatic Separator

Capacity: 1-3T/H or customizable

Feeding: 0-3mm

Application: separating magnetite, ilmenite, rutile, monazite, zircon, tungsten, tinstone, zirconite, andalusite, rutile, etc

Recommended Equipment

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.