Hammer Crusher

Capacity: 1-110t/h

Feeding size: <350mm

Output size: <10-35mm

Application: Crushing coal, salt, chalk, gypsum, brick, limestone, etc.

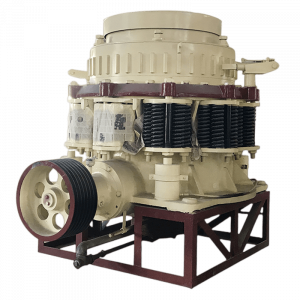

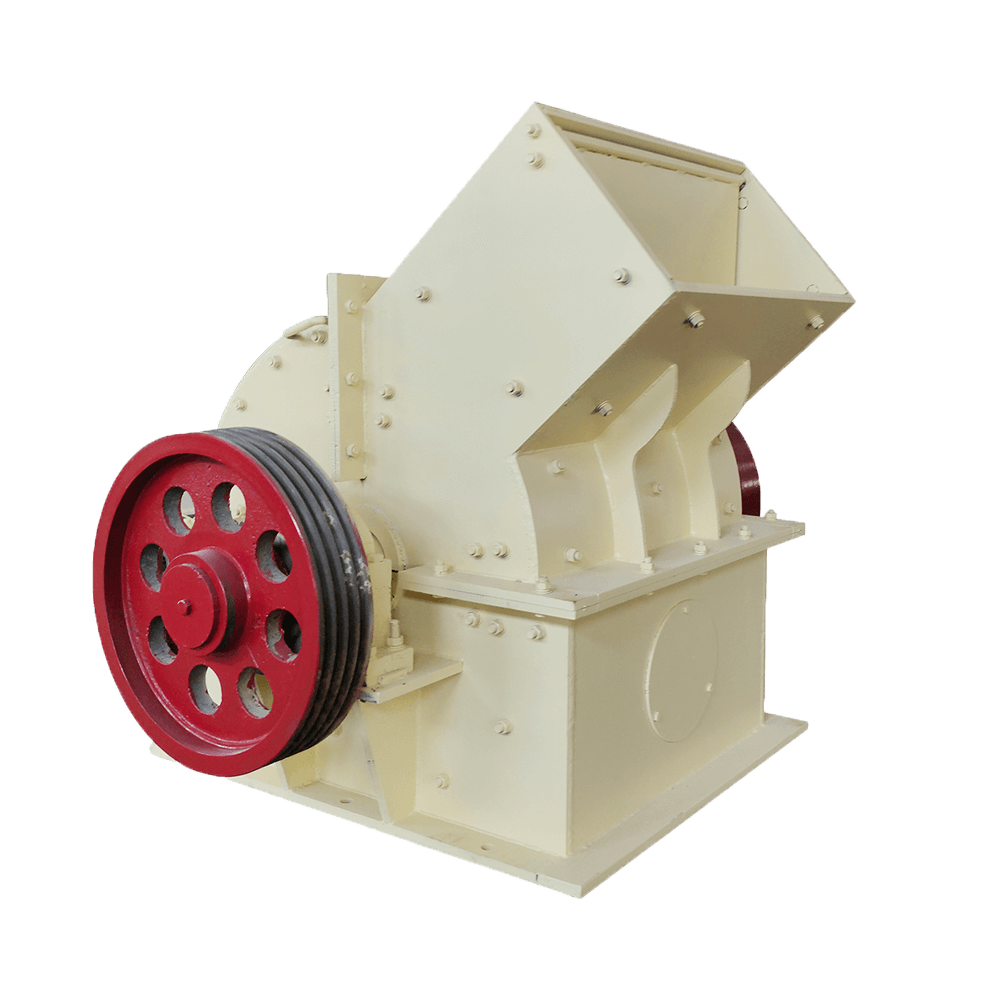

Products display

Introduction of Hammer Crusher

The hammer crusher is divided into ordinary hammer crusher and ring hammer crusher. The ring hammer is generally used in coal, coke and other industries. Ordinary hammer type machines are generally indicated by PC prefixes in English, and ring hammer crushers are generally indicated by PCH in English prefixes.

Hammer crusher has the characteristics of simple structure, large crushing ratio, high production efficiency, etc. It can be used for dry and wet crushing medium hardness and brittleness in mining, cement, coal, metallurgy, building materials, highways, combustion and other departments.

working principle of Hammer crusher

The motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the machine from the upper feed port and crushed by the impact, shearing and grinding of the high-speed hammer.

In the lower part of the rotor, there is a sieve plate, the particle size of the crushed material that is smaller than the size of the sieve hole is discharged through the sieve plate, and the coarse particle size larger than the sieve hole size is retained on the sieve plate to continue to be hit and grinded by the hammer, and finally passes the sieve plate out of the machine.

Why choose JXSC hammer crusher

features & Advantages of hammer crusher

- The hammer head of JXSC hammer crusher is cast from high manganese steel, which has high density, wear resistance and impact resistance.

- The production capacity is high and the products are uniform; the required discharging granularity can be adjusted according to customer requirements.

- The machine body structure is sealed, which solves the problems of dust pollution and ash leakage in the crushing workshop.

- We can customize fixed and mobile types and heavy-duty hammer crushers for large crushing production lines.

models & specifications

Model | Speed | Feed size | Out-put size | Capacity | Weight | Power |

PC-400×300 | 1450 | ≤40 | 0-10 | 1-3 | 0.8 | 11 |

PC-600×400 | 1000 | ≤220 | 0-15 | 5-25 | 1.5 | 22 |

PC-800×600 | 980 | ≤350 | 0-15 | 10-50 | 3.1 | 55 |

PC-800×800 | 980 | ≤350 | 0-15 | 10-60 | 3.5 | 75 |

PC-1000×800 | 1000 | ≤400 | 0-13 | 20-75 | 7.9 | 115 |

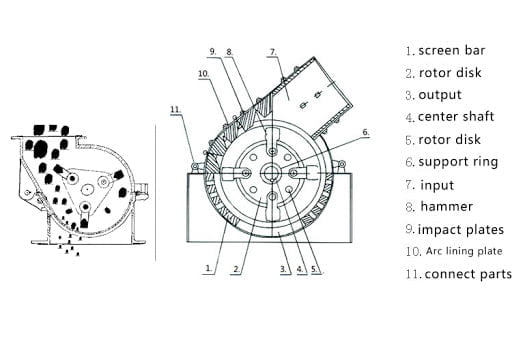

Structure of hammer crusher

The main working part of a hammer breaker is a rotor with a hammer (also called a hammer head). The rotor is composed of a main shaft, a disc, a pin and a hammer. The motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the machine from the upper feed port and crushed by the impact, impact, shearing and grinding of the high-speed hammer. There is a sieve plate at the lower part of the rotor. During crushing, the particle size smaller than the sieve hole size is discharged through the sieve plate. The coarse particle size larger than the sieve hole size is retained on the sieve plate to continue to be hit and ground by the hammer, and finally passes through the sieve plate Out of the machine.

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.