High frequency Vibrating Screen

Capacity: 10-250t/h

Layer: 1-4 available

Screen mesh: customized

Application: Screening of various sand and gravel, minerals, aggregates, rocks, etc; widely uesd in mineral processing industry.

Products display

Overview

Introduction: The high frequency vibrating screen is a mechanical device for screening, classifying and filtering granular materials, commonly used in mining, industry and laboratories. High-frequency screens are widely used in mineral processing, such as screening of iron ore, tin, tungsten, tantalum, niobium, alluvial diamond, etc. It is often used for dry and wet screening, classification and dehydration of various materials in coal preparation, chemical industry, brick making, food, pharmaceutical, alkali production, fertilizer, paper making and other industries.

Features of high frequency screen

- High-frequency screens have large processing capacity, high efficiency, small amplitude and high screening frequency;

- Whether processing minerals, aggregates or industrial by-products, solving various material screening equipment;

- Ensuring that finer particles can pass through the screen openings, thereby increasing overall productivity and throughput;

- Generally, nylon or stainless steel screen plates are used, which have long service life.

working principle of High frequency screen

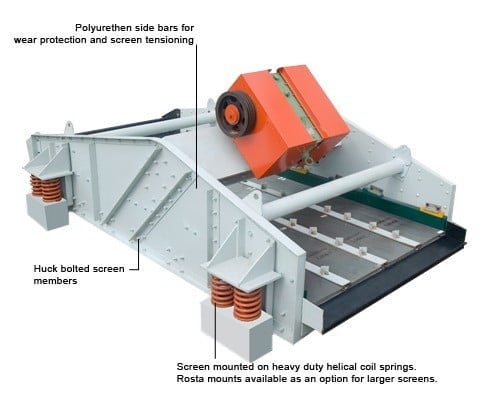

Main parts of the high frequency screen are mainframe, screen, electric vibrators, electric motor, rub spring and coupler.

The screening decks are capable of single to triple decks, greatly improve the screening efficiency and capacity. Besides, providing a thin and loose bed of particles, which as well as do a good effect on the screen.

Sieving is one of the oldest and most widely used physical size separation methods and is widely used in industry. In the continuous screening process, high frequency and low amplitude features lead to the vertical elliptical movement, the particles that fall from the feed hopper and reach the surface of the screen are sorted under the action of gravity. Oversized particles rebound along the screen, and most undersized particles pass through the holes.

models & specifications

| Model | JXSC-1036 | JXSC-1236 | JXSC-1536 | JXSC-1545 | JXSC-1836 | JXSC-1845 | JXSC-2045 | JXSC-2460 |

| Capacity(t/h) | 10-15 t/h | 18-65 t/h | 30-90 t/h | 30-90 t/h | 40-120 t/h | 40-120 t/h | 60-160 t/h | 80-250 t/h |

| Screening Surface Size (mm) | 1000*3600 | 1200*3600 | 1500*3600 | 1500*4500 | 1800*3600 | 1800*4500 | 2000*4500 | 2400*6000 |

| Sieve Size(mm) | Customized according to customer requirements | |||||||

| Double Amplitude(mm) | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 |

| Powder(kw) | 2*1.1 | 2*2.2 | 2*5 | 2*5 | 2*7.5 | 2*7.5 | 2*11 | 2*15 |

| Voltage(v) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

Related products

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.