Jaw Crusher

Capacity: 1-1120t/h

Feeding size: <800mm

Output size: <10-360mm

Application: The jaw crusher is used for coarse or fine crushing of high hardness ores, such as gold, copper, manganese, tin, iron, chrome, lithium, river pebbles, marble, calcite, limestone, basalt, quartz stone, etc.

Products display

Introduction of Jaw Crusher

Jaw crusher is a robust size reduction crushing equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries. Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with a capacity range of 1-1000tph. There are two types of feeding opening designs, rectangular and square shape. JXSC also provides multiple models or customized (fixed or mobile type)jaw crushers to meet various processing needs of users. The jaw crusher is the core equipment for primary crushing of mineral processing due to its durability, efficient coarse crushing and high adaptability.

Working principle Of jaw crusher

The working principle of the jaw crusher is mainly to crush materials through the periodic movement of the movable jaw. The motor drives the belt and pulley to move the jaw plate up and down through the eccentric shaft. When the movable jaw rises, it pushes the movable jaw plate closer to the fixed jaw plate. At the same time, the material is squeezed, rubbed, rolled and crushed in multiple ways. When the angle with the movable jaw plate becomes smaller, the materials are discharged from the lower opening of the crushing chamber. With the motor’s continuous rotation, the crusher’s jaw plate is crushed and discharged regularly to achieve mass production.

why choose JXSC jaw crusher

features & Advantages of Jaw crusher

- Advanced crushing process

It adopts a symmetrical “V” shape structure, commonly known as “Tiger’s Mouth”; the deep cavity crushing has no dead zone, and the materials will not block the crushing cavity, which improves production efficiency and has load-bearing solid capacity.

- High wear resistance of parts

The movable jaw is made of high-quality steel castings, and the eccentric shaft is made of forged blanks, etc., which increases the reliability of the equipment, is efficient, durable and has a long service life.

- Stable performance and energy-saving

It has a simple structure, easy maintenance and overhaul, and low operating costs; it consumes less energy, has low noise, and has less dust, creating a good production environment.

- Wide range of applications and flexible

The jaw crusher is the most widely used and is fully suitable for various sand and gravel, aggregate processing, mineral crushing plants, etc. The wide adjustment range of the discharge port increases the flexibility of the equipment.

models & specifications

| Model | Feeding size(mm) | Max feeding size(mm) | Discharging size(mm) | Capacity (t/h) | Motor power(kw) | Weight (t) | Overall dimension (LxWxH)(mm) |

| PE-150*250 | 150*250 | 130 | 10-60 | 3-15 | 5.5 | 2.2 | 1000x1450x900 |

| PE-250*400 | 250*400 | 210 | 20-80 | 5-20 | 15 | 2.8 | 1450x1315x1296 |

| PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 30 | 6.65 | 1565x1732x1586 |

| PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 55 | 11.73 | 1890x1916x1870 |

| PE-600*900 | 600*900 | 500 | 65-180 | 80-180 | 55-75 | 16.13 | 2305x1840x2298 |

| PE-750*1060 | 750*1060 | 630 | 80-180 | 110-320 | 90-110 | 28 | 2450x2472x2840 |

| PE-800*1060 | 800*1060 | 680 | 100-200 | 140-340 | 90-110 | 30 | 2610x2556x2800 |

| PE-870*1060 | 870*1060 | 750 | 170-270 | 180-360 | 90-110 | 31.22 | 2660x2556x2800 |

| PE-900*1060 | 900*1060 | 780 | 200-290 | 200-380 | 90-110 | 31 | 2690x2556x2800 |

| PE-900*1200 | 900*1200 | 780 | 95-225 | 220-450 | 110-132 | 49 | 3335x3182x3025 |

| PE-1000*1200 | 1000*1200 | 850 | 195-280 | 280-550 | 110-132 | 51 | 3435x3182x3025 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 | 4200x3732x3843 |

| PE-1500*1800 | 1500*1800 | 1200 | 210-360 | 525-1120 | 280-335 | 132 | 5100x4700x4300 |

| PEX-150*250 | 150*250 | 125 | 10-40 | 1-3 | 5.5 | 2 | 896x745x935 |

| PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 15 | 3.5 | 1380x1658x1025 |

| PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 30 | 4.96 | 1545x1667x1330 |

| PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 | 1530x1992x1380 |

| PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 37-45 | 8.52 | 1900x2192x1430 |

| PEX-300*1300 | 300*1300 | 250 | 20-90 | 25-95 | 55-75 | 12.6 | 1750x2320x1724 |

| PEX-350*1200 | 350*1200 | 300 | 70-140 | 25-120 | 75 | 12.35 | 2162x2220x1723 |

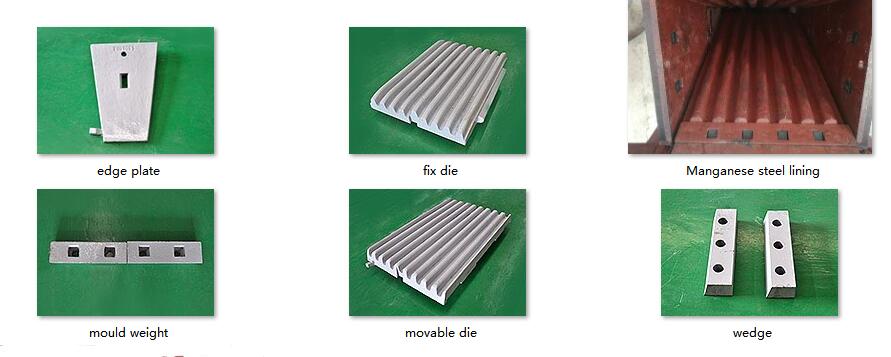

Main parts

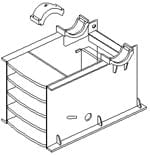

1. Base Frame

The welding type adopts the welding method of large arc transition fillet and low stress area, which greatly reduces the stress concentration, ensures the equal strength of the rack in all directions, and has the characteristics of impact resistance, uniform force, and low failure rate.

The assembly type adopts a modular, welding-free frame structure design with high strength and reliability. At the same time, the assembly design of the whole machine is more convenient for transportation and installation. It is especially suitable for installation in small, difficult transportation places such as underground and high-altitude mines.

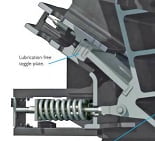

2. Toggle plate

3. Adjustment system

The assembly process of the adjustment components: the toggle pad is fixed to the adjustment seat by angle steel and bolts, and the adjustment gasket is placed between the adjustment seat and the lower frame.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.