Gravity Separation Equipment

Mineral Processing » Equipment » Gravity Separation

JXSC has more than 38+ years of experience in manufacturing mineral gravity separation equipment. Mainly includs jig separators, mobile jig concentrator plants, Gemini shaker tables, shaking tables(gravimetric tables), spiral chutes(spiral separators), and centrifugal concentrators. It is very suitable for fine and heavy mineral concentration operations such as ferrous metals, rare metals and precious metal ores. JXSC is committed to continuously optimizing machines performance to ensure that it provides customers with efficient and reliable gravity separation equipment.

Applicable: gold, copper, lead-zinc ore, manganese, chrome, tantalum, niobium, tin, tungsten, ilmenite, rutile, monazite, garnet , quartzite, magnetite and zircon sand, or other heavy mineral concentrator solutions.

gravity separation equipment for sale

Gravity separation equipment, referred to as mineral gravity separator, uses the difference in specific gravity between different minerals and separates different minerals with the help of gravity or centrifugal force to achieve the best mineral processing effects.

Our gravity separation machines can effectively handle coarse-grained, medium-grained and fine-grained ores with little mud. It has the advantages of strong adaptability, high sorting recovery rate and low cost. We have rich experience in producing mining gravity separators and are controlled by professional technicians; contact us for more details and price!

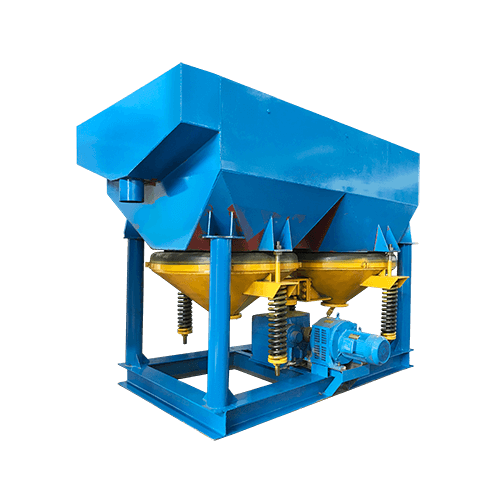

Jig Separator

Capacity: 1-25t/h

Suitable for gold, diamond, tantalum-niobium tin ore, barite, coltan, manganese ore processing.

• Large beneficiation capability, high concentrate.

• Wide feed and particle size recovery.

• Energy saving and environmental protection.

Shaking Table

Capacity: 10-20 t/d, Up to 60t/d

Apply for gold, copper, tantalum-niobium, chrome, beach sand, and other ore separation.

• Good separation efficiency, easy adjustment.

• Durable, corrosion-resistant bed surface.

• Simple operation, high cost-effectiveness.

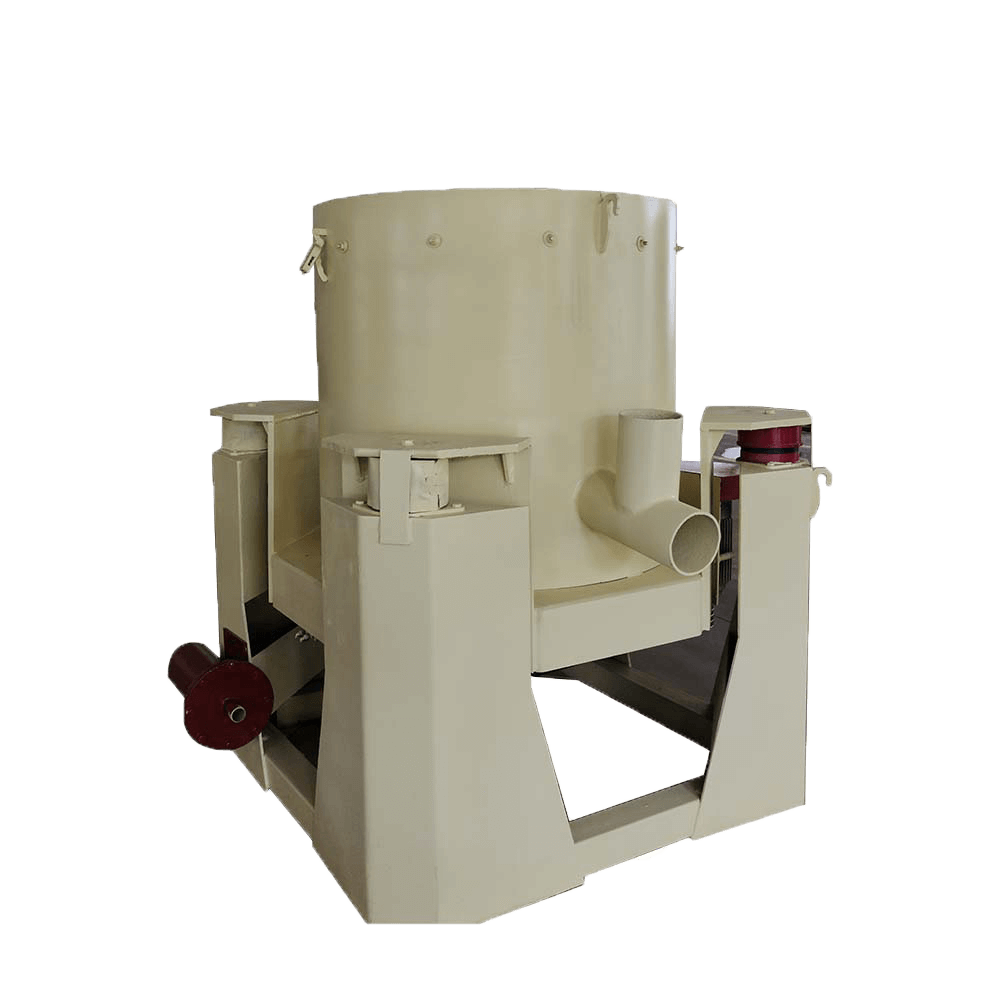

Gold Cnetrifugal Concentrator

Capacity: 0.5-60 TPH

Ideal for concentration and recovery of gold from placer gold, vein gold and polymetallic ores.

• Good recovery rate of fine minerals.

• Continuous output of concentrate and tailings.

• Extremely efficient, stable operation, low cost.

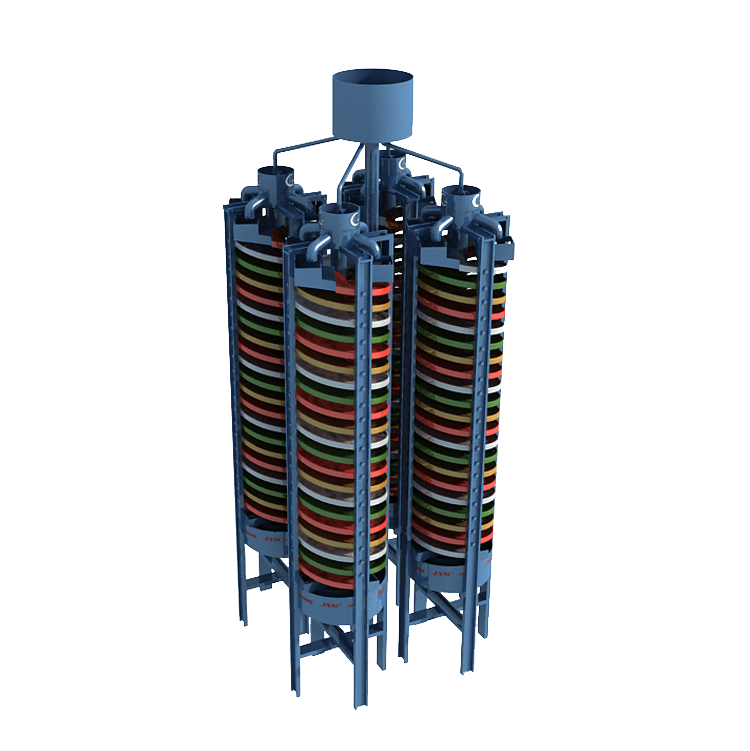

Spiral Chute

Capacity: 0.15-10 t/h

Spiral separator is suitable for silica sand, zircon sand, titanium ore, cobalt ore, rutile or other mineral sand separation.

• Small footprint, large processing capacity.

• High enrichment ratio and recovery rate.

• Moisture-proof, rust-proof, corrosion-resistant.

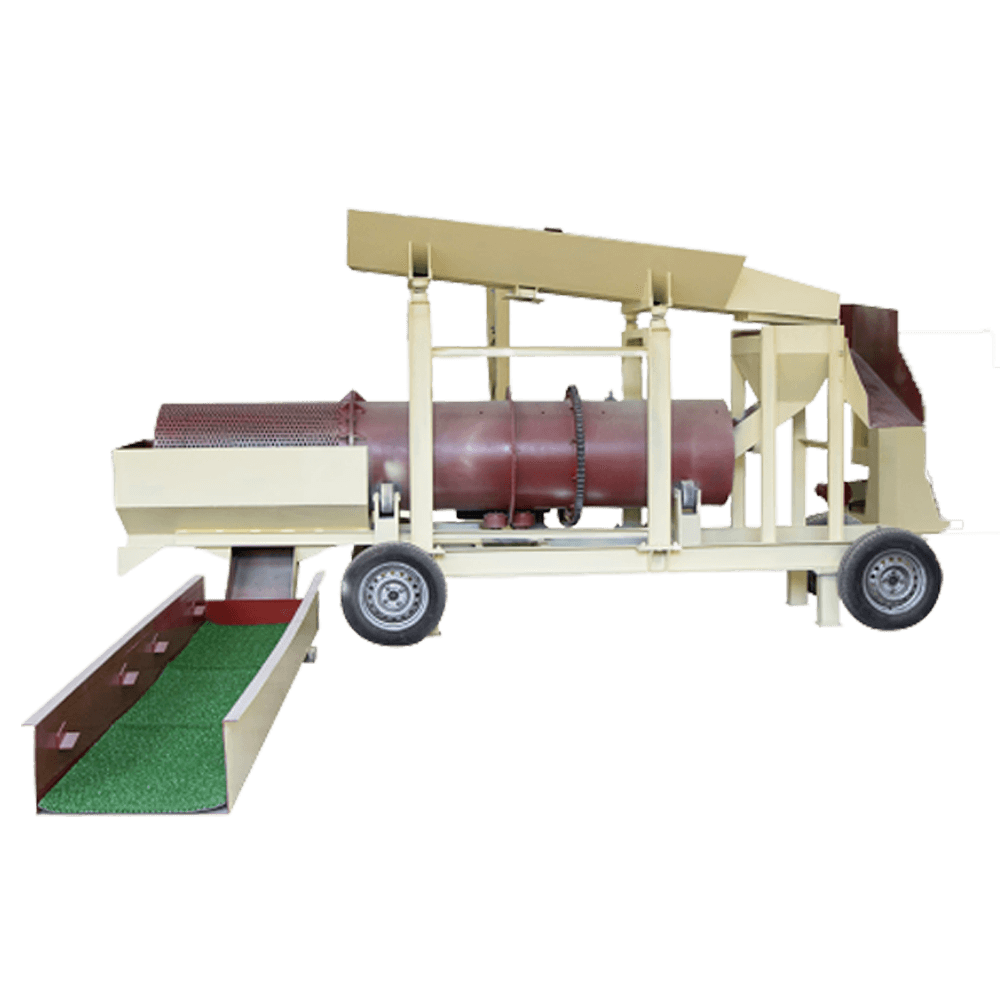

Mobile Jig Concentrator

Capacity: 1-20 TPH

Mounted small trommel screen or trommel scrubber with jig; One-stop gold and diamond washing processing plant.

• Use less water and save energy.

• Movable, fast deployment, customizable.

• Integrated washing, screening and separating.

Gemini Shaker Table

Capacity: 0.1-1.2t/h

Good effect on gold concentrate recovery.

• Large enrichment ratio and sorting precision .

• Unique design, low energy requirements and maintenance.

• Adjustable, high-quality components and durable materials, long service life.

gravity Separation equipment Application cases

Recommended Products

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.