Dense Medium Separation

DMS(dense medium separation) is especially useful for separating valuable minerals with relatively high gangue densities. It is often used in the processing of diamond, coal and various base metal ores.

The mineral DMS process enables the mining industry to increase overall recovery efficiency by concentrating valuable minerals while reducing waste volumes.

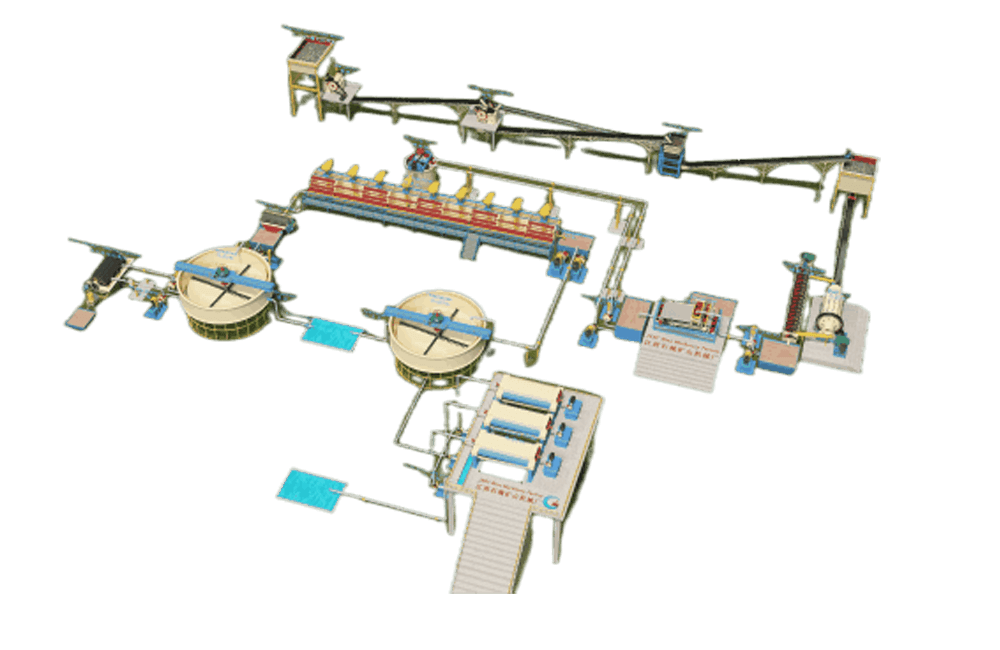

DMS Process Solution

Dense Medium Separation process

Among them, a commonly used equipment for the DMS process is a dense medium cyclone (DMC), which can separate dense media according to the difference in specific gravity.

1. Crushing: The material is first crushed to a smaller size to facilitate the release of valuable minerals from the gangue.

2. Prepare the suspension: usually a finely ground ferrosilicon or magnetite suspension in water. The density of the media is carefully controlled to achieve the desired separation efficiency. Among them, the density of the dense medium is between valuable minerals and gangue, making it possible to separate them according to their density difference.

3. Mixing: The crushed ore is mixed with the dense medium in a specific mixing device. Dense media separates valuable minerals from waste based on density.

4. Separation: The mixture of material and dense medium is sent to the DMS separator, usually a dense medium cyclone separator. Due to the density difference between the mineral and dense media, the material is subject to buoyancy forces inside the separator. As a result, less dense gangue particles float to the top; denser and valuable minerals sink to the bottom.

5. Collection and discharge: The separated gangue and valuable mineral fractions are collected separately. The valuable concentrate is then processed further, while the gangue material may be discarded or sent for further processing, depending on its economic value.

DMS (Dense Medium Separation) Processing

Dense medium separation (DMS) or heavy media separation is a pre-concentration technique used to reject gangue minerals before grinding. DMS exploits the difference in specific gravity between the target and gangue minerals, and is also used in the separation of spodumene from other gangue silicates. The specific gravity of spodumene is between 3.1 and 3.2; this makes it slightly heavier than most gangue minerals such as quartz (2.65), albite (2.60) and muscovite (2.8). The spodumene, therefore, sinks while gangue minerals float in dense medium of appropriate specific gravity, and thus separated from each other.

Related Products

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.