300-400TPH Granite Crushing Screening Plant In Nigeria

We guarantee the high quality machine in the mineral processing industry, established in 39+ years of experience.

Project Info

- Materials: granite

- Capacity: 300-400TPH

- Feed size:>100mm

- Output size: 0-6mm、6-13mm、13-19mm、19-25mm

- Location: Nigeria

Process

Feeding- Crushing – Screening

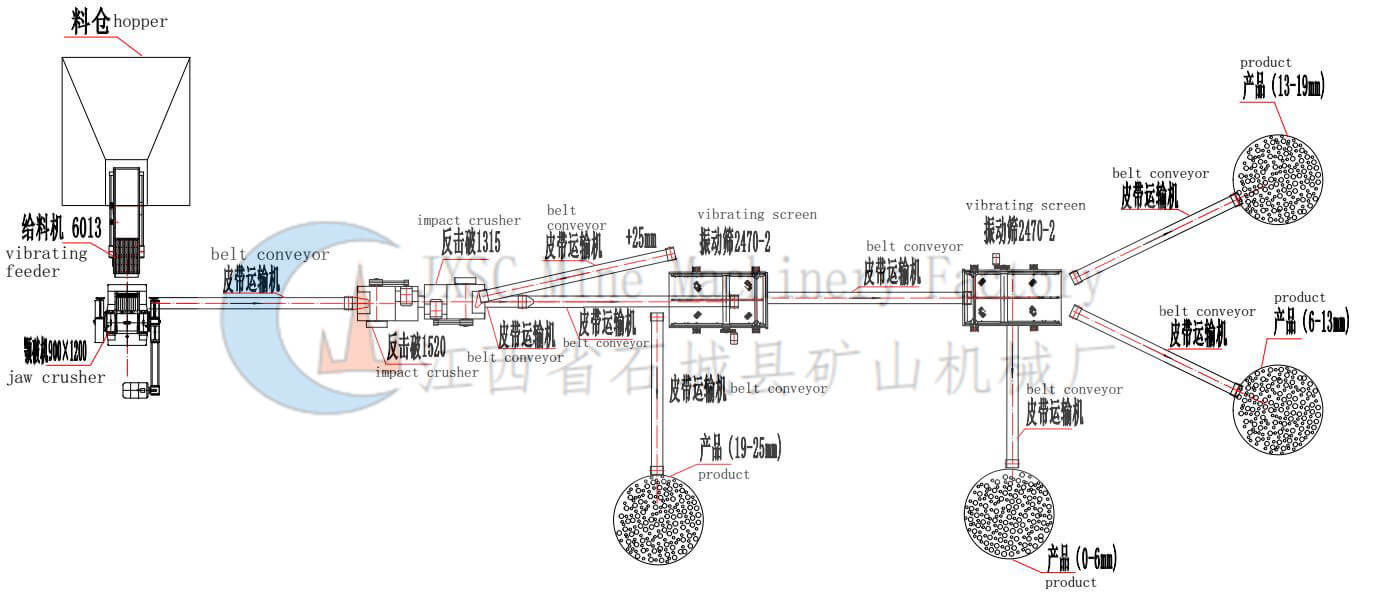

process flow

300-400TPH Granite Crushing Screening Plant flow

According to the customer’s requirements, we will provide him with the following services:

1. Design the entire plant flow chart and machine layout based on the granite stone engineering conditions.

2. Provide complete sets of crushers.

3. Ship all machines to Nigeria in batches.

4. Provide technical support and installation guidance.

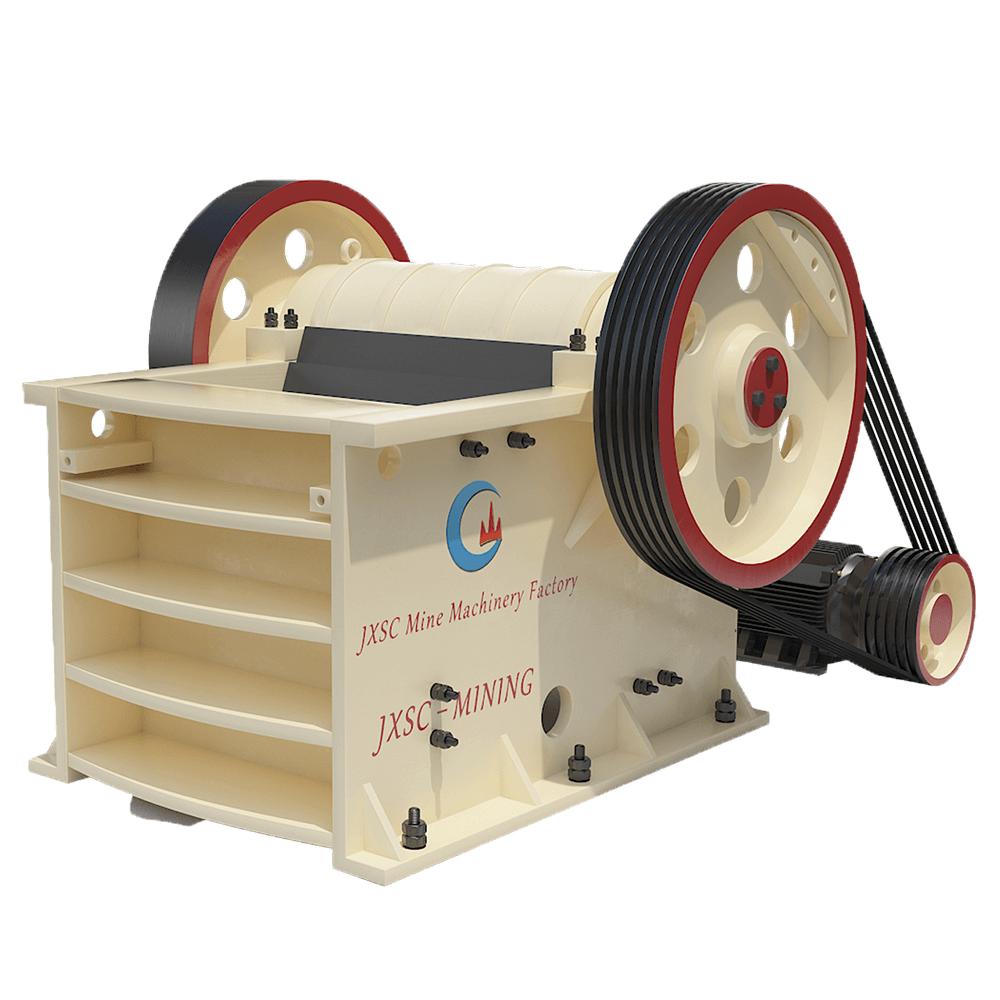

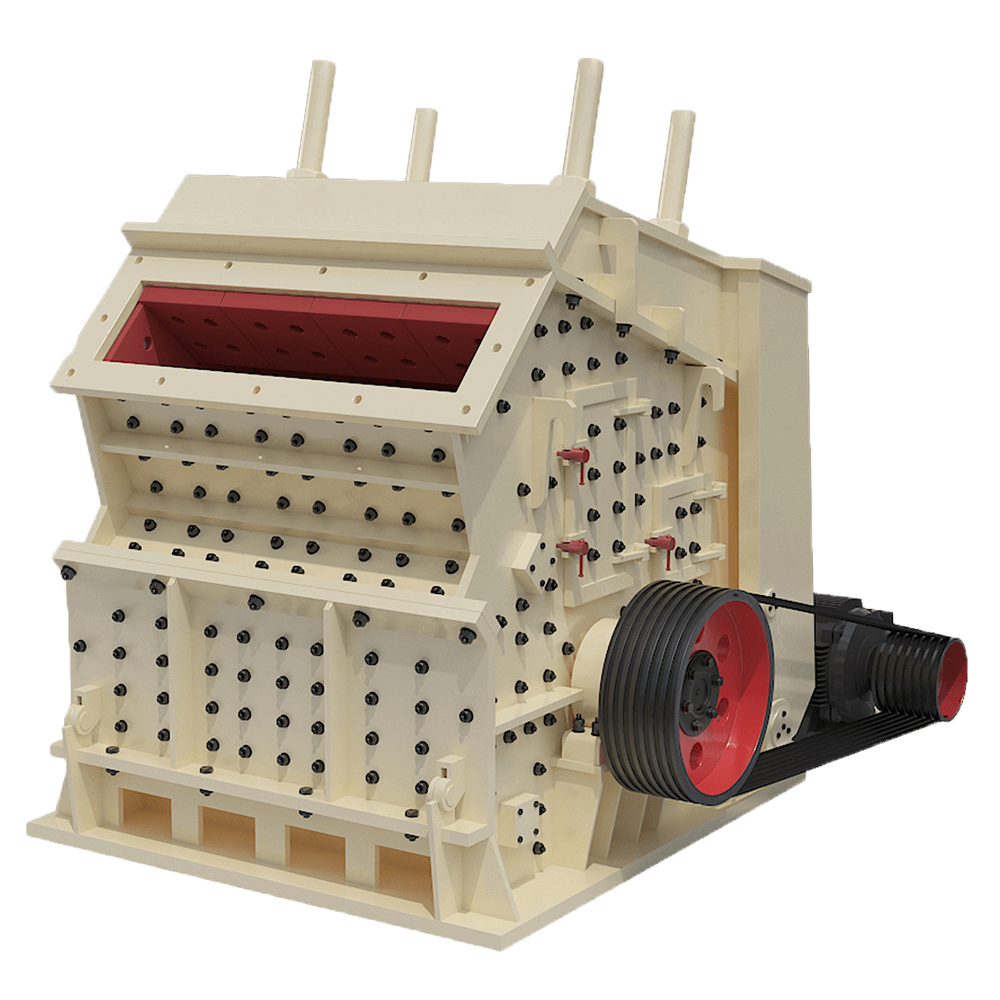

JXSC designed a complete 300-400TPH granite crushing screening plant for Nigerian customers, mainly including jaw crusher, impact crusher, vibrating screen, belt conveyor, etc. The following is the specific process:

First, the material enters the silo, passes through the grille to remove large particles, and then falls into the vibrating feeder. The materials are evenly sent to the jaw crusher for coarse crushing, and then sent to the two impact crushers by the belt conveyor for fine crushing in order to reach the appropriate size. All materials are then screened out by the first vibrating screen into two materials. Among them, 19-25mm materials are transported aside. Materials smaller than 25mm pass through the second vibrating screen, and the materials are screened into three sizes: 0-6mm, 6-13mm, and 13-19mm.

Now, the plant had finished installation and conducted empty test run, the client is very satisfied with the empty test run result.

Four final product sizes are available in the plant, and we can adjust the discharge size of the impact crusher and replace the vibrating screen to obtain different final product sizes. This equipment is easy to operate and maintain, and can also be used to crush different types of rock aggregates, such as river rocks, limestone, basalt, etc. JXSC can customize the most suitable rock crushing solutions based on your quarry conditions and your plant’s end product requirements. Welcome to contact us for more details and quotation.

Main Equipment

Product Name | Model No. | Quantity (Set) |

Vibrating grizzly feeder | DN600*130 | 1 |

Jaw crusher | PE-900*1200 | 1 |

Impact crusher | PF1520 | 1 |

Impact crusher | PF1320 | 1 |

Circle vibrating screen | 2YD2470 | 2 |

Belt conveyors | B1200 | 3 |

Belt conveyors | B1000 | 2 |

Belt conveyors | B800 | 4 |

Electric control cabinet | / | / |

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.