Gold Centrifugal Concentrator

Capacity: 0.5-60 TPH(ton per hour)

Feeding size: 0-6mm

Application: The centrifugal concentrator is widely used for the gold recovery of alluvial gold, vein gold ore, and polymetallic ore, and separating tailings; it can also be used for the beneficiation of gold-bearing heavy sand washed by chute and gold dredger.

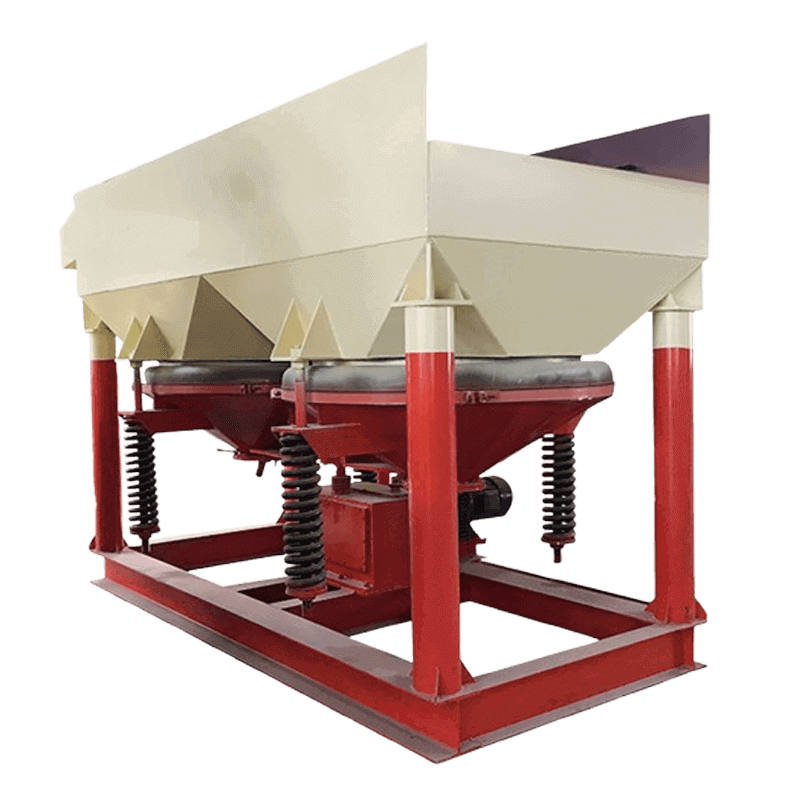

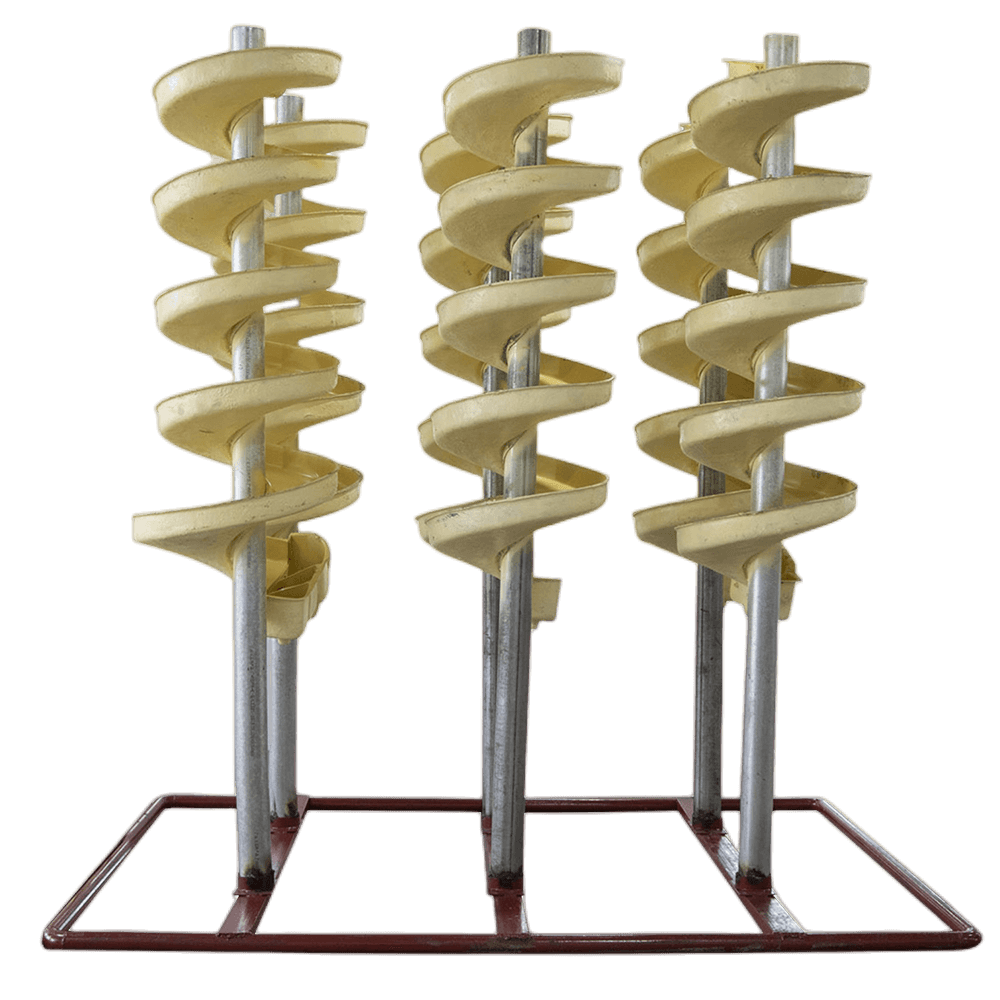

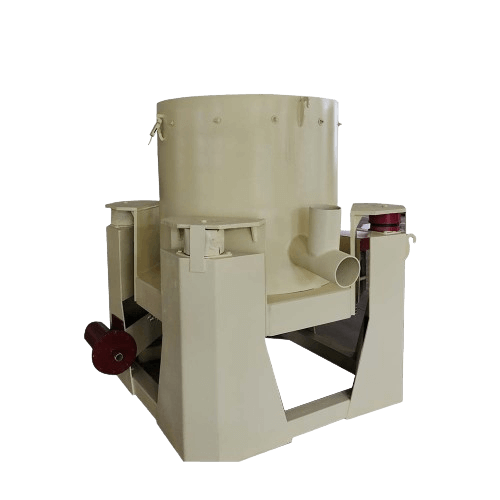

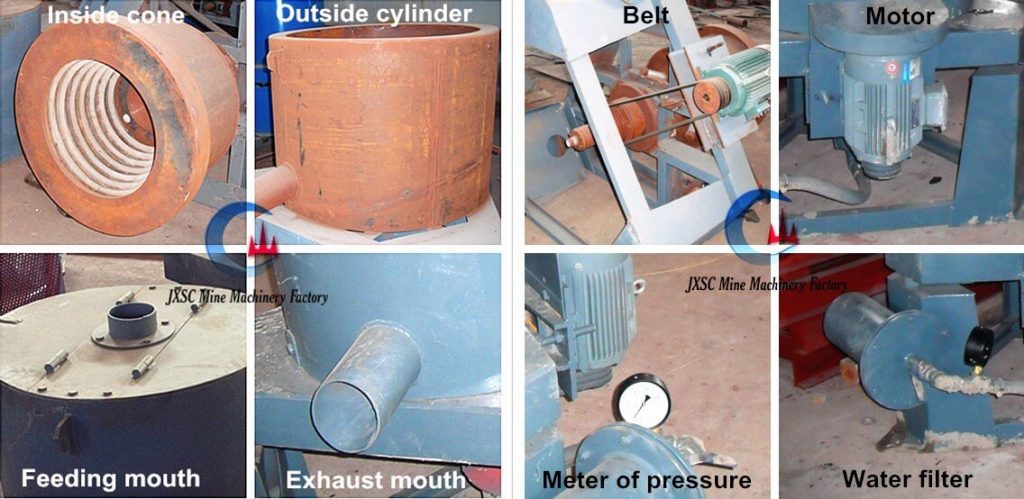

Products display

introduction of gold Centrifugal Concentrator

The gold centrifugal concentrator rotates at a high speed, generating a high “G” force, which can separate small gravity recovery gold (less than 50 microns). The centrifugal concentrator can also recover the tailings of gold, chromite, scheelite and other heavy minerals. So as to make better use of the mineral concentrate.

Centrifugal concentrators are mainly used for placer gold mining and rock gold beneficiation, such as river alluvial gold and seashore gold placer concentrating, vein gold ore re-selection or tailings reprocessing. With its low cost and good recovery of fine minerals, it has become an irreplaceable core gravity separation equipment in modern gold beneficiation, especially suitable for low-grade resources and environmentally friendly gold extraction scenarios.

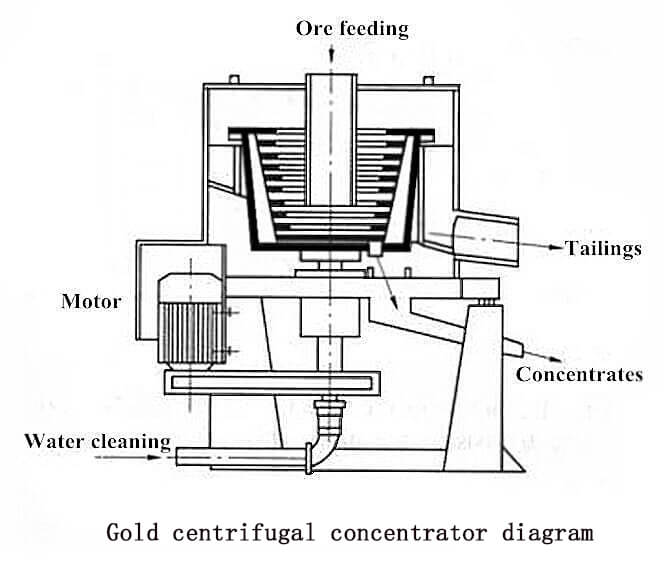

Working principle of Centrifugal Concentrator

Gold centrifugal concentrator is a gravity enhancement device. The powerful centrifugal force generated by the high-speed rotation of the centrifuge rotor is used to accelerate the settling speed of particles in the liquid. It mainly separates materials with different sedimentation coefficients and buoyancy densities in the materials.

Heavy minerals precipitate on the inner wall of the drum and become concentrate, which rotates with the drum. The light minerals are washed away on the surface of the concentrate layer along the slope of the drum and become tailings; they flow into the ore receiving trough and then flow into the tailings trough through the ore discharge separator.

Why Choose JXSC Gold Centrifugal Concentrator

features & Advantages of Centrifugal Concentrator

1. Often connected with gold trommel scrubber, trommel screen, shaking table, sluice box and other beneficiation equipment, used in alluvial gold processing plants.

2. Recovering fine gold from alluvial gold ores with extremely efficient, and low cost.

3. Continuous output of concentrate and tailings, high concentrate yield, recovery rate, and high enrichment ratio.

4. No mercury/cyanide pollution, in line with green environmental protection gold separation standards.

5. Good wear resistance of wearing parts, simple maintenance, compact design, small footprint, easy to integrate into the process of the existing concentrator.

models & specifications

Model | Capacity (t/hr) | Feeding Size(mm) | Feeding Density(%) | Power Requirement (kw) | Cone Rotate Speed | Back Water Required(m3/h) | Dimension(mm) |

STLB20 | 0.5-1 | 0-2.5 | 20-50 | 1.1 | 800 | 15 | 800*560*710 |

STLB30 | 2-3 | 0-4 | 20-50 | 2.2 | 600 | 20 | 1280*1030*1135 |

STLB60 | 8-12 | 0-6 | 20-50 | 7.5 | 460 | 50 | 1850*1550*1600 |

STLB80 | 10-20 | 0-6 | 20-50 | 15 | 400 | 80 | 2300*1800*2200 |

STLB100 | 40-60 | 0-6 | 20-50 | 18.5 | 360 | 100 | 2400*2400*2250 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.