Belt Conveyor

Capacity: 10-350TPH

Feeding: <800mm

Application: Material all kinds of ore, waste, tailings, steel slag, etc transport.

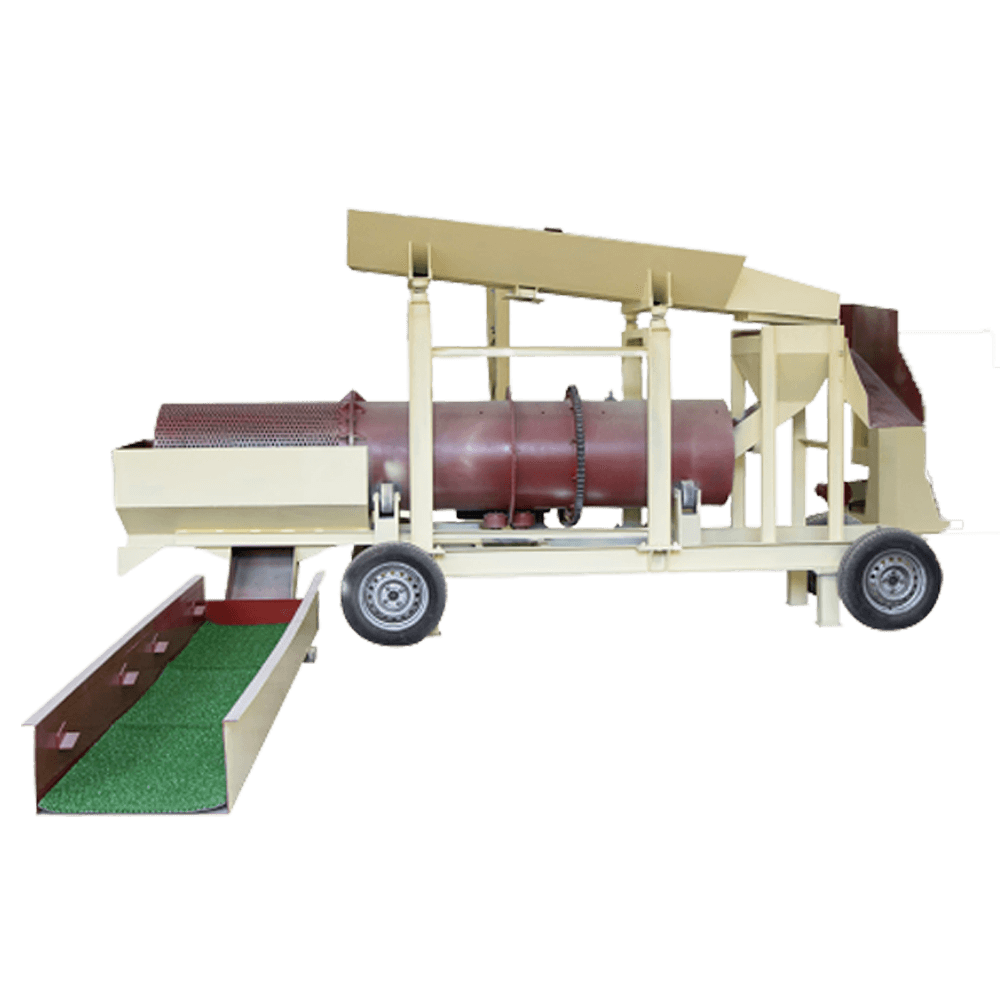

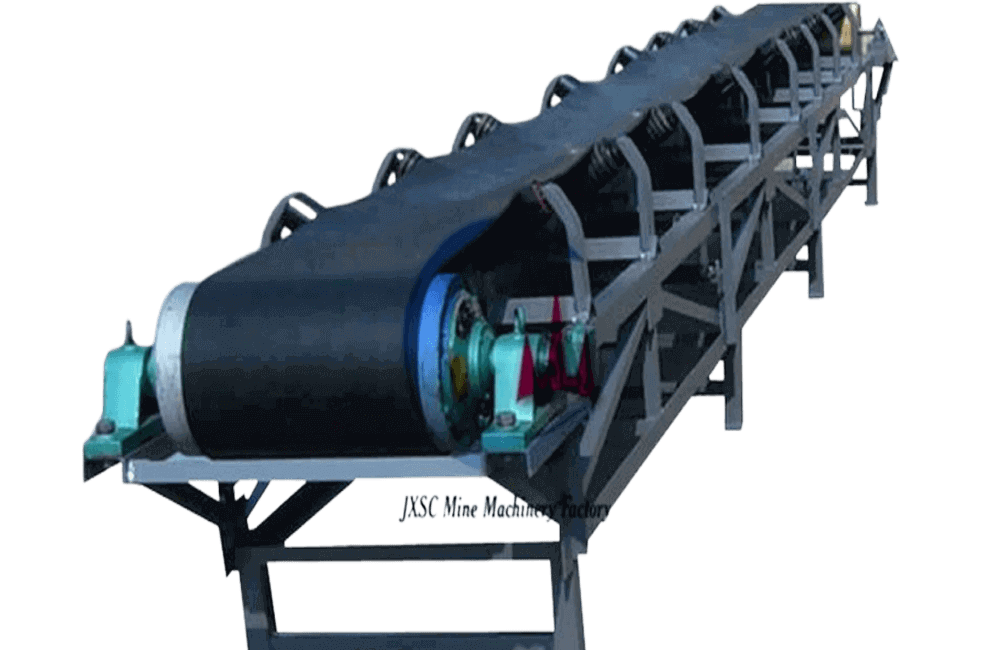

Products display

introduction of belt conveyor

We’re providing belt conveyors mainly for mining applications. It can seamlessly integrate with crushing processing, receiving and handling material from the production line.

Application: JXSC belt conveyors are designed to handle and move mediums in mineral processes, such as material inside a factory and bulk material handling. It also transports large volumes of resources and processed ores, such as gravel, sand, coal, ore, alluvial, overburden, etc.

Working principle of Belt Conveyor

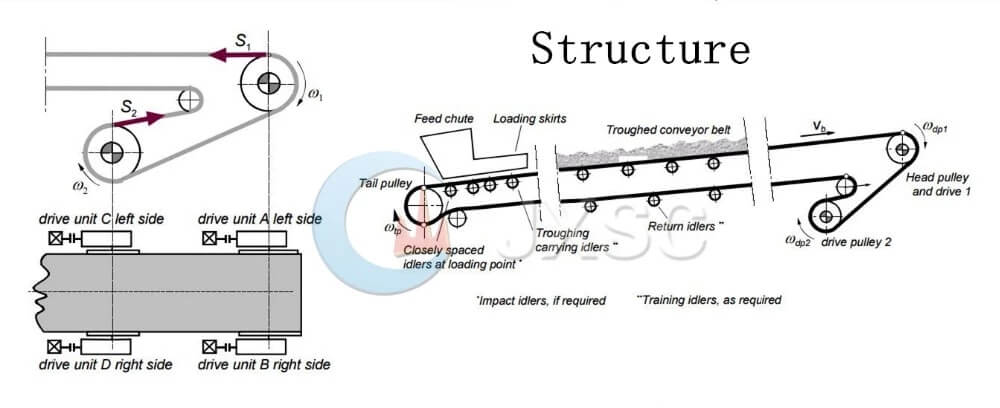

The belt conveyor mainly comprises two end rollers and a closed conveyor belt tightly sleeved on them. The pulley that drives the conveyor belt to rotate is called a drive pulley (drive pulley); the other pulley that only changes the direction of movement of the conveyor belt is called a reversing pulley.

Material is fed on the feed-side and lands on the rotating conveyor belt, which relies on the conveyor belt friction to deliver to the discharge end. It has the advantages of strong conveying capacity, long conveying distance, large transport volume and continuous conveying.

why choose JXSC belt conveyor

Features & advantages Of belt conveyor

1. This belt conveyor can adapt to different forms of materials such as granular, powdery, and blocky, and has wide versatility;

2. It can be arranged to transport in different directions such as vertical, horizontal or inclined according to requirements, and has a wide adaptability;

3. It can transport materials over long distances sustainably, has strong carrying capacity, and has a simple structure and is easy to maintain;

4. It reduces the time and labor intensity of manual handling and improves the overall efficiency of the production line.

models & specifications

Model | Capacity | Max length | Belt width | Speed | Upper slope | Power | Drum dia | Roller Dia |

DT75-500 | 87 | 20 | 500 | 1 | <20 | 5.5 | 500 | 89 |

DT75-650 | 127 | 20 | 650 | 1 | <20 | 7.5 | 500 | 89 |

DT75-800 | 198 | 15 | 800 | 1 | <20 | 7.5 | 630 | 89 |

DT75-1000 | 507 | 20 | 1000 | 1.25 | <20 | 11 | 800 | 108 |

DT75-1200 | 742 | 20 | 1200 | 1.25 | <20 | 15 | 1000 | 108 |

DT75-1400 | 1032 | 30 | 1400 | 1.25 | <20 | 22 | 1000 | 133 |

Our JXSC’s troughed belt conveyor consists of a wide belt typically running on three idler rolls. The outer wing rollers are sloped upwards to form the trough shape. The troughed belt then travels over the idler sets to transport the load. A conventional troughed belt conveyor has the following components:

★ Idlers. These are rollers with bearings that form a trough shape for the belting. The idler sets are typically spaced out between one and three meters.

★ Belting. The belting, which carries the load, rests on the idler rollers. Our conveyor products the typical arrangement of the idlers supporting the belt. The belt is pulled around in a loop with tension/power supplied by drive pulley(s).

★ Drive. The pulleys and drives are used to move the belt.

★ Pulleys. The conveyor belt forms a loop. The carry side transports the load and the return side allows continuous cycling of the belt. The pulleys allow the belt to change direction at the loading and discharge ends, as well as direction changes on the return side.

★ Transfer chute. This is where the material is loaded onto or discharged from the belt.

★ Conveyor take-up system. The take-up applies tension to the belt to limit the sag between the idlers and prevent slip at the drive pulley. The take-up pulley moves to tension the belt. Take-up systems are typically gravity, but can be winch, screw or hydraulic jack. The typical arrangement has a pulley mounted on a trolley. The trolley is connected to a gravity mass in a tower via a cable.

Related Products

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.