Small Portable Crusher plant

Processing capacity: 1-1200t/h, customizable

Applicable industries: mining, quarry, construction waste recycling, aggregate production, sand making plant, etc.

Applicable materials: crushing construction waste, iron ore, limestone, river stone, pebbles, basalt, granite, marble, hard rock, etc.

Advantages:

- Powerful engines, high performance crushing capacity;

- Allows easy mobile between operating locations;

- Time-saving, flexibility and low cost.

Types of Portable Crusher plant

small-Large mobile Crusher plant for sale

Small portable/ mobile crusher plants can easily crush various materials and have strong flexibility, bringing new conveniences to the user. These portable rock crusher plants offer efficient solutions for small-large construction and mining projects with compact size and extreme flexibility. Its integrated design simplifies the process, allows easy one-stop feeding and crushing plants. The plant can also add screening processes later to achieve a more efficient oprations. It can be easily transported to different locations, allowing cost-effective operations without compromising productivity. This mobile device is often integrated with various rock crushers or other equipment for small-large crushing plant, including jaw crushers, hammer crushers, impact crushers, cone crushers, sand-making machines, vibrating screens, etc.

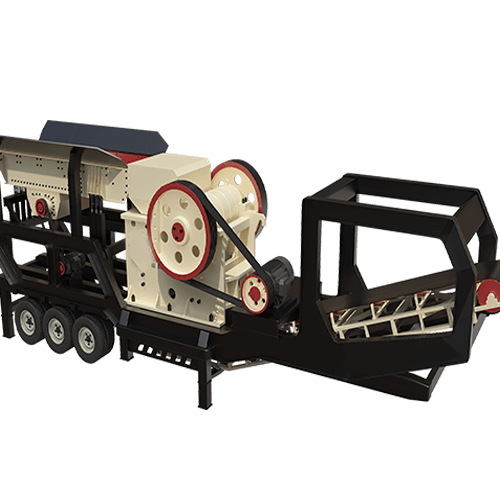

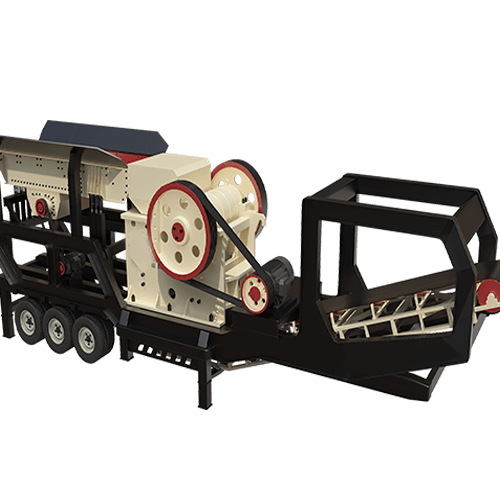

1. Portable Jaw Crusher plant

Capacity: 1-1120t/h

Configuration: feeder + jaw crusher + belt conveyor

Applicable Materials: quartz, granite, basalt, limestone, cobblestone, iron ore, copper ore, dolomite, calcite, etc.

Process: The feeder quietly but efficiently supplies a steady stream of raw material to the primary crusher. The function of a jaw crusher is to crush large rocks into smaller size for further processing. Then the belt conveyor continuously supplies the materials to another place.

Advantages:

- It can be quickly deployed on different construction or mining project sites;

- Powerful jaws exert pressure on the material, efficiently reducing its size.

- Seamless material flow can be achieved to ensure continuous production and optimal utilization of resources;

2. Portable hammer Crusher plant

Capacity: 1-1200t/h

Configuration: feeder + hammer crusher + belt conveyor

Applicable Materials: gravel, granite, basalt, limestone, river stone, marble, iron ore, copper ore, coal, gold ore, etc.

Process: Beginning with the feeding stage, raw materials are carefully poured into the feeder, where powerful hammers quickly break large rocks into smaller size, more manageable pieces. The material passes through a conveyor or screening device and is further refined and separated to achieve specific size requirements.

Advantages:

- Powerful hammering mechanism provides efficient and high-quality crushing performance;

- Continuous flow ensures a stable supply of crushed materials.

- The final product is consistent in size and quality, meeting specific project requirements.

3. Portable impact Crusher plant

Capacity: 30-500t/h

Configuration: feeder + impact crusher + belt conveyor

Applicable Materials: granite, basalt, limestone, quartz, pebbles, talc, iron ore, copper ore, dolomite, diabase, gold ore etc.

Process: The feeder ensures a stable supply of material to the impact crusher, and then the impact crusher crushes the rock through the high-speed rotating rotor. The crushed material is then efficiently transported via belt conveyors for further processing or disposal.

Advantages:

- Advanced control system that can accurately adjust the rotor speed and impact curtain;

- Powerful impactor and high-performance crushing capacity;

- Simplified crushing process, low cost and high production efficiency.

4. Portable jaw crusher + impact crusher plant

Configuration: feeder + jaw crusher + impact crusher + belt conveyor

Process: The materials through the feeder to the jaw crusher for primary crushing. It then through a belt conveyor and into an impact crusher to produce fine or application-specific molding materials efficiently.

Advantages:

- Versatile applications from crushed limestone, granite, concrete, and other rocks/ ores/ aggregates;

- Integrated operation realizes feeding-coarse crushing-fine crushing process at the same time.

- Not only does it save time, it also reduces the need for multiple machines in various locations;

5. Portable jaw crusher + hammer crusher plant

Configuration: feeder + jaw crusher + hammer crusher + belt conveyor

Process: The material is fed into the jaw crusher through the feeder, and the powerful jaw plate exerts huge force to crush large rocks into smaller size. The coarsely crushed materials are conveyed to the belt conveyor, which guides them to the hammer crusher. The high-speed rotating hammer crushs the material into finer size suitable for further processing or transportation.

Advantages:

- It can process various materials including hard rock, stone, aggregate and minerals;

- Its machine combines mobile, versatility, efficiency and environmental awareness;

- Quick assembly and disassembly capabilities enable rapid deployment, minimizing downtime and increasing on-site productivity.

Small Portable Crusher

Small portable or mini mobile crushers are versatile and efficient machines. Its compact structure and easy transportation provide a simple solution for sand, gravel, aggregate, rock stone and mineral processing plant.

- With continuous crushing, low energy consumption.

- Easy maintenance, low cost.

- Motor or diesel engine driven.

Related Equipment

JXSC rock crushers include jaw crushers, hammer crushers, impact crushers, cone crushers, and roller crushers. It can also be combined with a vibrating screen, belt conveyor, vibrating feeder, or wheel to form one-stop feeding-crushing-screening plants. We can customize fixed and mobile crushers to suit small-large rock crushing lines.

Related Solutions

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.