Shaking Table

Capacity: 10-20 t/d, Some model max capacity up to 60 t/d

Application: Tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, titanium, manganese, iron ore, coal, etc.

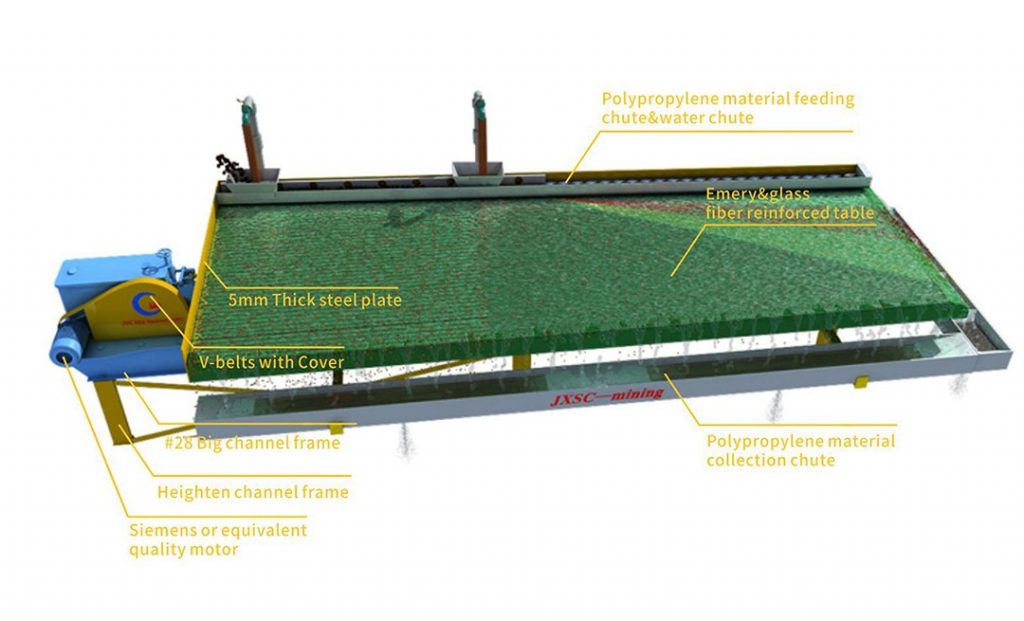

Advantage:

- Lightweight and corrosion-resistant Polypropylene materials feeding chute and collection chute

- High-quality & wear-resisting fiberglass deck

- Heighten steel stand for more convenient feeding

- Protective cover for belt wheel that ensures safe production

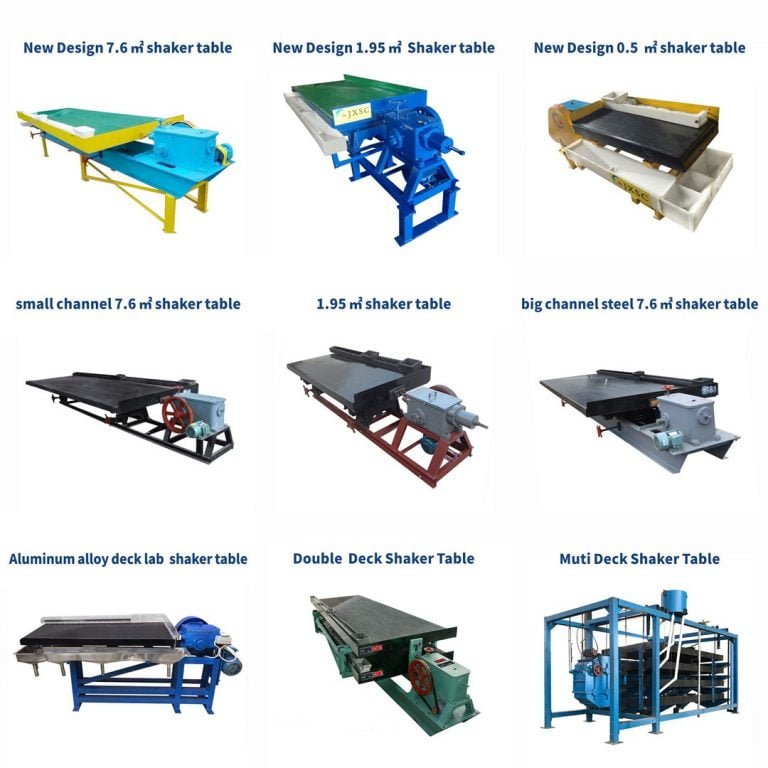

Types of shaking table

JXSC manufacturer provides all kinds of popular types of shaker tables, factory direct price for sale.

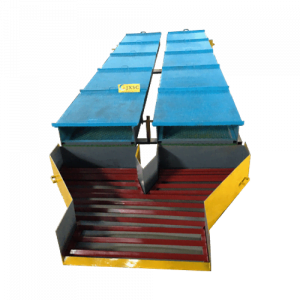

Our shaker tables by deck numbers: Single-deck shaker tables; Double-deck shaker tables; Mult deck shaker tables

Introduction of shaking table

The shaking tables (gravimetric tables, shaker tables, gold shaking table) are the most widely used and efficient gravity separation equipment for fine ore separation. It is widely used in the beneficiation of rare metals and precious metal ores, such as gold, copper, tin, tantalum, niobium, iron, manganese, chromium, etc. It can be used for roughing, concentrating, scavenging separation and other mineral processing stages. The shaking table can produce a variety of products including high-grade concentrate, secondary concentrate, middlings and tailings at one time, and is an important ore separation equipment.

working principle of shaking table

The ore are fed from the ore feeding trough at the corner of the shaking table bed, and the horizontal flushing water is supplied from the feeding trough. Mainly on an inclined bed surface, with the help of the combined action of symmetrical reciprocating motion of mechanical stone slabs and thin-layer inclined plane water flow. The mineral particles on the bed surface according to specific gravity and water flow impulse so that the minerals are sorted according to different densities. Finally, the ore particles with different specific gravity and particle sizes gradually flow down in a fan shape along their respective directions of movement. It’s discharged from other areas on the concentrate end and tailings side of the shaking table, respectively, thus forming concentrate, middlings and tailings.

Why Choose JXSC shaking table

Features & advantages of shaking table

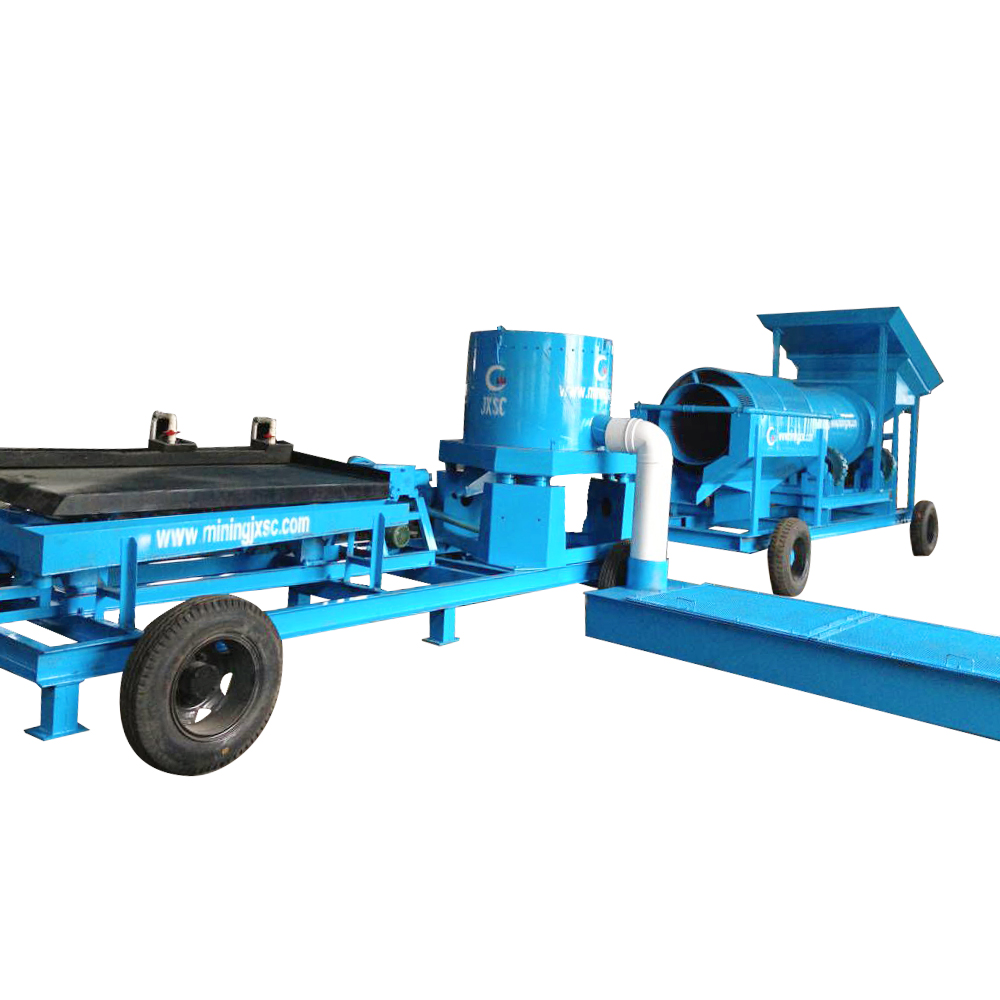

- It is often connected with gold trommel scrubber, trommel screen, centrifuge concentrator, sluice box and other beneficiation equipment, and is used in alluvial gold processing plants.

- It has the advantages of high enrichment ratio, good separation efficiency, easy care, easy adjustment and simple operation, and can obtain the final concentrate and tailings at one time;

- The bed surface is flat, has good corrosion resistance, is durable, not easy to deform, has a long service life, and does not need to be replaced frequently;

- Easy installation, simple operation, low cost, high cost performance, good sorting performance and stable indicators.

models & specifications

Deck type | Unit | Coarse sand | Fine sand | Slime Deck | Three different kinds of decks are available | |||

Beneficiation Area | m2 | 7.6 | 7.6 | 7.6 | 4.08 | 1.95 | 0.5 | |

Deck Size | Length | mm | 4450 | 4450 | 4450 | 3000 | 2100 | 1100 |

transmission end width | mm | 1855 | 1855 | 1855 | 1320 | 1050 | 500 | |

Concentrate end width | mm | 1546 | 1546 | 1546 | 1100 | 850 | 430 | |

Maximum Feeding Size | mm | 2 | 0.5 | 0.15 | 0.1-2 | 0.074-2 | 0.074-2 | |

Feeding Amount | t/d | 30-60 | 10-20 | 15-25 | 0.4-1.5t/h | 0.3-0.8t/h | 0.05-0.2t/h | |

Process Capcity | t/h | 1.5-2 | 0.8-1.5 | 0.5-0.8 | 0.4-1.5 | 0.3-0.8 | 0.05-0.2 | |

Feeding Density | % | 25-30 | 20-25 | 15-25 | 10-30 | |||

Stroke | mm | 16-22 | 11-16 | 8-16 | 6-30 | 12-28 | 9-17 | |

Frequency | f | 45-48 | 18-53 | 50-57 | 210-320 | 250-450 | 280-460 | |

Water added | t/d | 80-150 | 30-60 | 10-17 | 0.3-1.5t/h | 0.2-1t/h | 0.1-0.5t/h | |

Transverse slope of Deck | / | 2° 30-4° 30 | 1° 30-3° 30 | 1° -2° | 0 -10° | 0 -8° | 0 -10° | |

Longitudinal slope of Deck | / | 1.4 | 0.92 | —— | —— | —— | —— | |

Cross-section Shape of Deck | rectangular | saw tooth | triangle | Avaliable rectangular, saw tooth, triangle | ||||

Motor Power | KW | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |

1. Laboratory small shaker table, deck size 1100*500*430mm

2. Standard shaker table, deck size 2100*1050*850mm

3. 6S small shaker table, deck size 4500*1850*1560mm

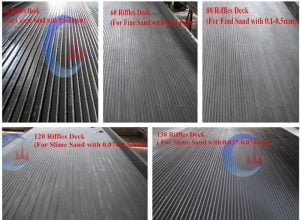

According to different feed particle size, 6S shaker is separately suited for coarse sand, fine sand, slime. There are 5 different grooves available: 46/60/88/120/138.

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.