Impact crusher

Capacity: 30-500 t/h

Feeding size: <700mm

Application: The impact crusher is used for all kinds of coarse, medium, and fine materials (granite, limestone, concrete, etc.) with compressive strength not exceeding 350MPa.

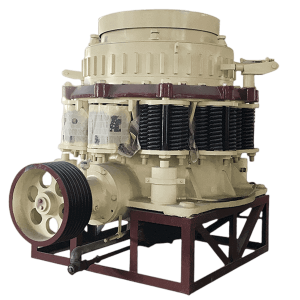

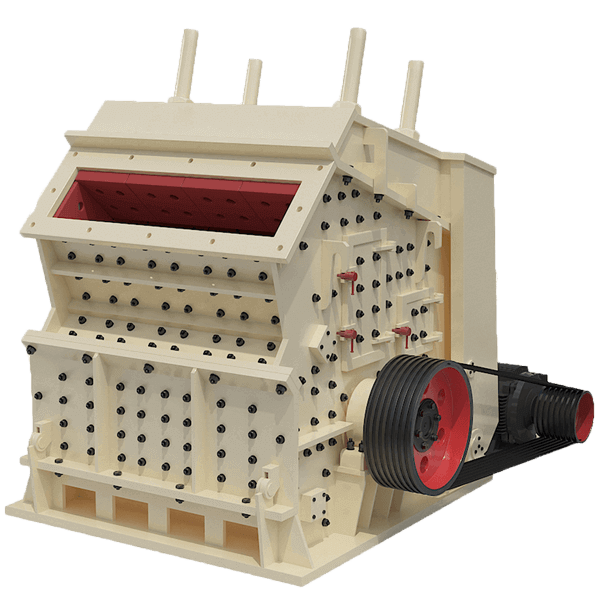

Products display

Introduction of impact crusher

Impact crushers are widely used in mineral, rock, stone, and aggregate processing plants, with high production efficiency and good safety performance. It’s mainly used for medium or fine crushing of materials with medium hardness or below (such as limestone, coal gangue, shale), and produce uniform finished product particle size (generally 0-50mm). With high-speed rotating rotor + plate hammer impacting materials, the crushing ratio is large (up to 50:1), and the finished product particle shape is excellent. According to the arrangement type of impact rotor and shaft, impact crushers can be divided into horizontal shaft impact crushers (HSI) and vertical shaft impact crushers (VSI).

The materials crushed by impact crusher are mostly in cube shape, which is suitable for the production of high-quality sand and gravel aggregates and building materials. It can also be designed as mobile impact crusher plants. With the characteristics of high crushing ratio, good particle shape and flexible control, it has become the core crushing equipment for medium and soft materials.

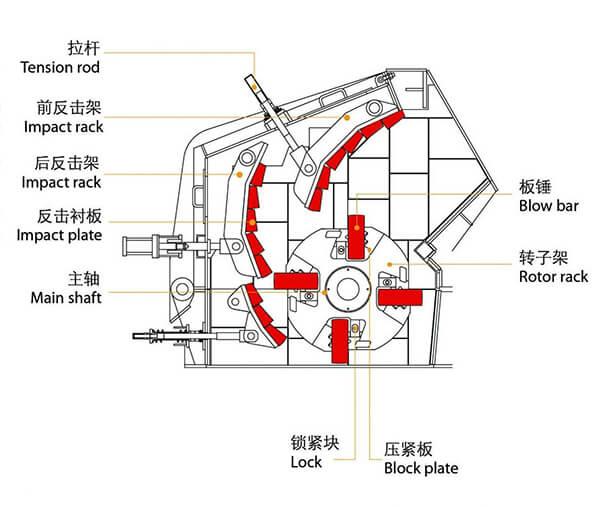

working principle of impact crusher

The V-belt connected with the motor drives the impact crusher to rotate in a fixed direction. There are multiple sets of suspension impact plates above the rotor. The material enters the crushing cavity through the feeding hole and guide rail. The blower rod fixed on the rotor impacts the material onto the counter-attack plate and then falls from the counter-attack plate onto the colliding material blocks.

Therefore, the materials move repeatedly in the crushing cavity composed of the rotor, the impact plate, the hammer and the striking rod. By adjusting the angle and distance of the impact anvil, the gap between the impact plate and the hammer can be adjusted according to actual needs. You can control product throughput by varying rotor speed, input feed, and grind screen configuration.

Why choose JXSC impact crusher

features & Advantages of impact crusher

1. The crushing cavity is large and the feed particle size range is wide; the crushed finished particles are cubic and have good particle shape.

2. The impact crusher is more effective in processing materials with large amounts of moisture and effectively prevents material clogging.

3. Its rotor is powerful and crushes harder materials with minimal energy consumption.

4. JXSC impact crusher can adjust the discharge particle size in various ways, such as adjusting the rotor speed, the gap between the impact plate and the grinding chamber, etc.

5. This impact crusher adopts high-chromium blow hammer and unique impact liner, which are wear-resistant and have high utilization rate.

6. High efficiency and energy saving: a single machine can complete multiple stages of crushing, simplify the process, and consume less energy than the traditional jaw crusher + cone crusher combination.

7. Adapt to wet and sticky materials: the model without grate design can reduce blockage, which is better than the hammer crusher.

models & specifications

Model | Rotor Spec (mm) | Feed opening size (mm) | Max Feed edge(mm) | Capacity (t/h) | Motor Power(kw) | Weight(t) | Overall Dimension |

PF1007 | 1000*700 | 400*730 | 300 | 30-50 | 37-55 | 9.5 | 2400*1558*2660 |

PF1010 | 1000*1050 | 400*1080 | 350 | 50-80 | 55-75 | 12.2 | 2400*2250*2620 |

PF1210 | 1250*1050 | 400*1080 | 350 | 70-120 | 110-132 | 14.9 | 2690*2338*2890 |

PF1214 | 1250*1400 | 400*1430 | 350 | 130-180 | 132-160 | 18.6 | 2690*2688*2890 |

PF1310 | 1300*1050 | 490*1170 | 400 | 80-140 | 110-160 | 16.2 | 2780*2478*2855 |

PF1315 | 1320*1500 | 860*1520 | 500 | 160-250 | 180-260 | 19.3 | 3096*3273*2667 |

PF-1320 | 1320*2000 | 860*2030 | 500 | 160-350 | 300-375 | 28 | 3096×3560×3185 |

PF-1520 | 1500*2000 | 1315*2040 | 700 | 300-500 | 400-450 | 42.8 | 3890×3560×3220 |

Structure of impact crusher

Main parts are hammer bar, rotor shaft, anvils, grinding screen, vibrating belt, casing.

The rotor shaft is designed to withstand the torsion and bending. The grinding screen is designed control the output particle quality from the crusher.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.