10TPH Feldspar Processing Plant In Nigeria

We guarantee the high quality machine in the mineral processing industry, established in 35 years of experience

minerals

Raw feldspar ore contains iron, calcium, mica and other impurities

capacity

10TPH

feed size

0-200mm

Customer's request

remove iron, mica and other impurities to obtain high grade feldspar

process flow

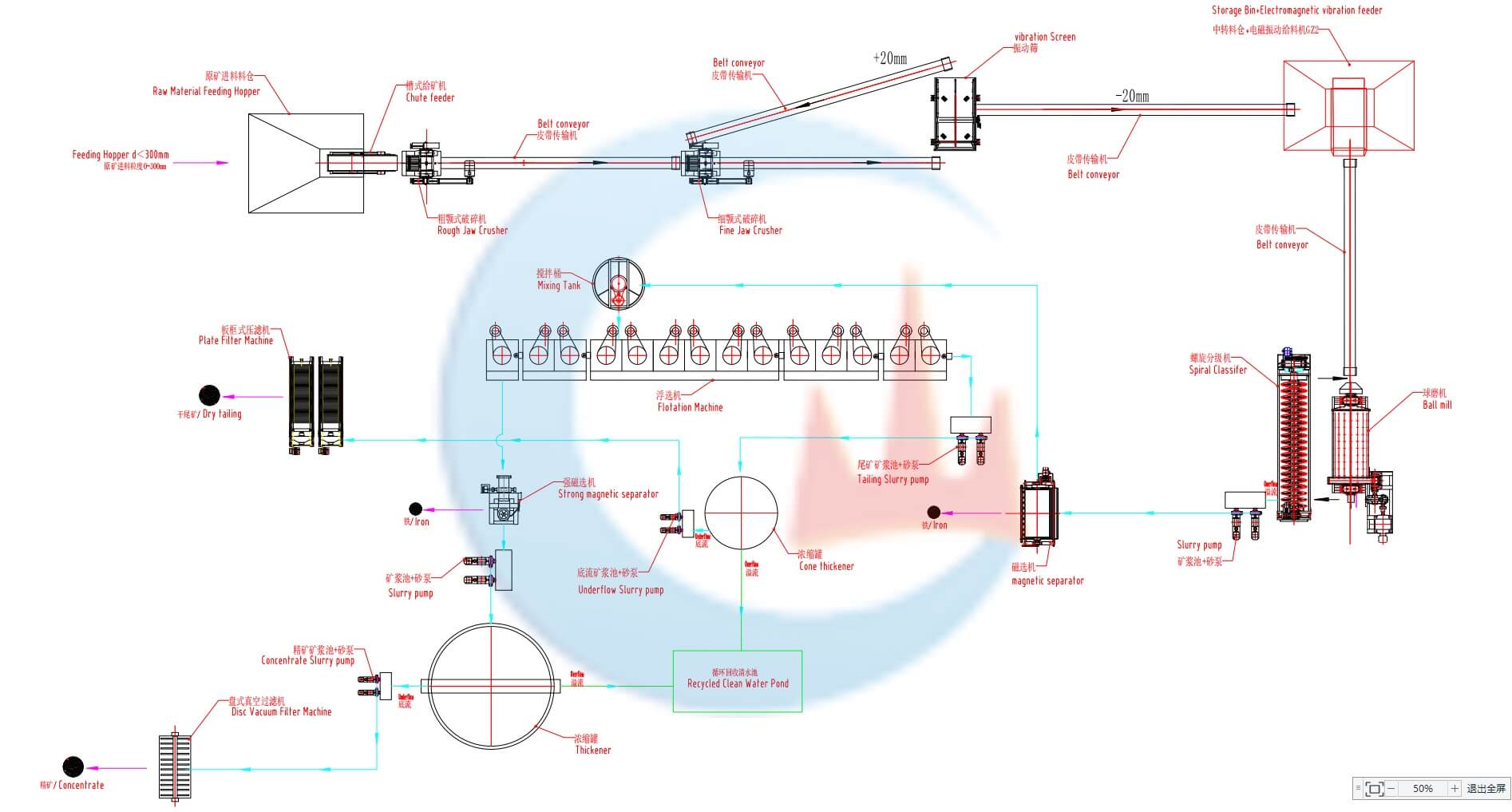

10TPH Feldspar Processing Plant flow details:

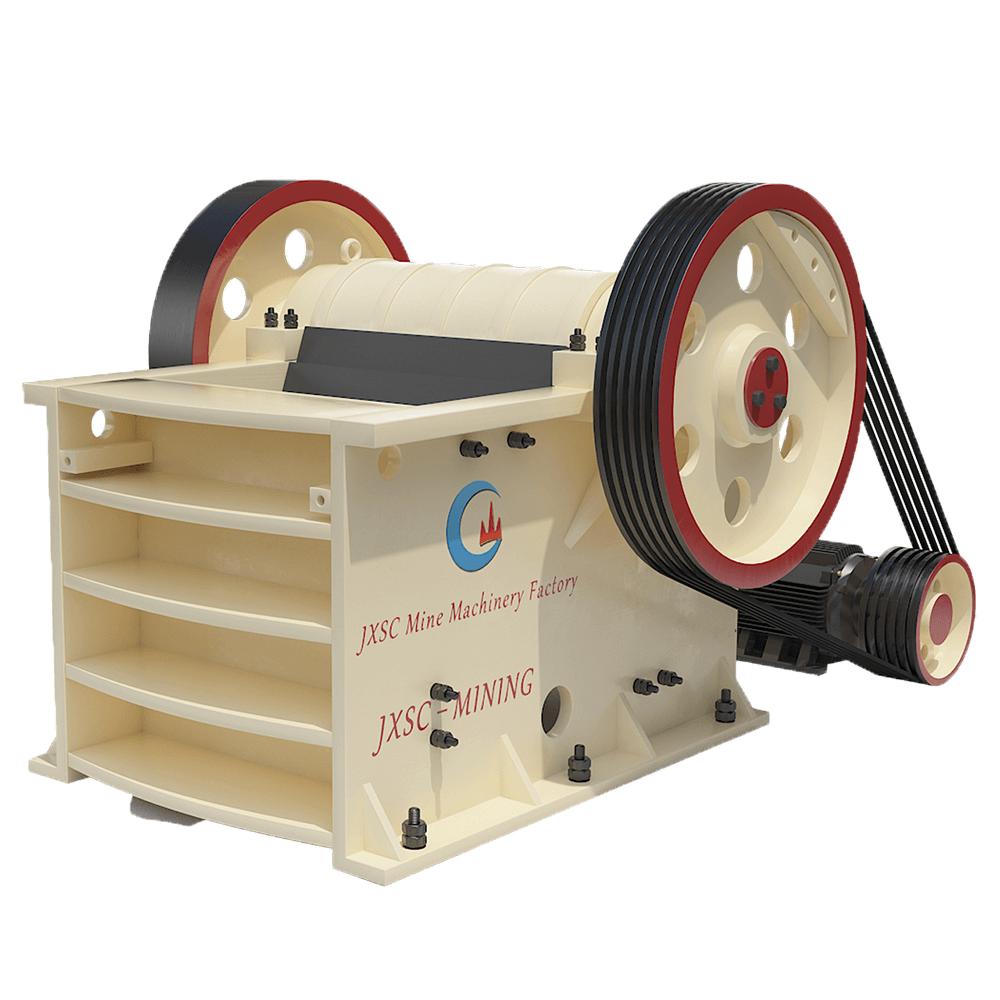

1. Crushing & Screening: jaw crusher, vibrating screen

Utilize rough jaw crusher, fine jaw crusher and vibrating screen to form a closed crushing circuit, so as to make 200mm rock ore down to 20mm. Thus, it makes sure the particle size of the material entering the grinding section is qualified.

2. Grinding section: ball mill, spiral classifier

Utilize ball mill and spiral classifier to form closed grinding circuit, so as to achieve more than 90% discharging size 200mesh(0.074mm). Thus, it makes sure the particle size of the material entering the flotation section is qualified.

3. Magnetic separation: magnetic separator

A two-stage magnetic separation process of low-intensity magnetic separation and high-intensity magnetic separation was used to remove magnetic minerals in feldspar ore to the maximum extent. Low-intensity magnetic separation can remove magnetite(Fe3O4), and high-intensity magnetic separation can remove hematite, limonite, ilmenite(Fe2O3).

4. Flotation section: flotation machine

The flotation process is used to remove impurities in the feldspar ore further, so as to obtain high grade feldspar concentrate.

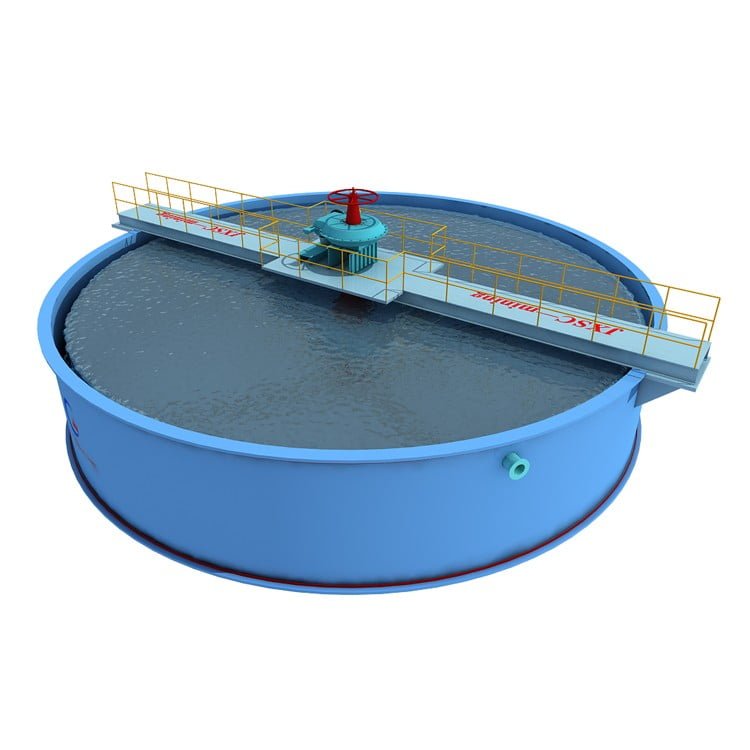

5. Dewatering process for concentrate: thickener, disc vacuum filter machine

The dewatering process for the concentrate utilizes a thickener and disc vacuum filter machine. Use a slurry pump to send concentrate to the thickener, the overflow of thickener goes to a clear water pond, and the underflow goes to disc filer machine for dehydration. After being dehydrated by a disc filter machine, the moisture concentration is less than 10%.

6. Tailing dry discharging process: cone thickener, llate filter machine

All tailings are first pumped to cone thickener for adjusting the suitable concentration, the overflow of cone thickener go to recycled clear water pond, and the underflow go to plate filter machine for dehydration, finally the moisture of tailing is less than 10%, this is tailing dry discharging process.

Feldspar Processing Plant Solutions & Flow Design

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.