Flotation machine

Capacity: 0.1-50m³/min per cell

Application: flotation machine is widely used in copper, gold, silver, zinc-lead, nickel, fluorite, antimony ore, molybdenum ore, phosphate ore, lithium, feldspar, fluorite, talc, iron, rutile or other mineral processing plants; It can also be used for separation of ferrous metals and non-metals.

Introduction of flotation machine

The flotation machine is important for realizing the flotation process. It can process metal or non-metal minerals, such as copper, lead-zinc, lithium, antimony, fluorite, talc, etc. After the minerals undergo wet grinding, the minerals dissociated into monomers are adjusted into a slurry of a certain concentration. It is sent to the flotation equipment after being fully mixed with flotation chemicals in the stirring tank. JXSC flotation machine has a large air suction volume and low power consumption.

Working principle of flotation machine

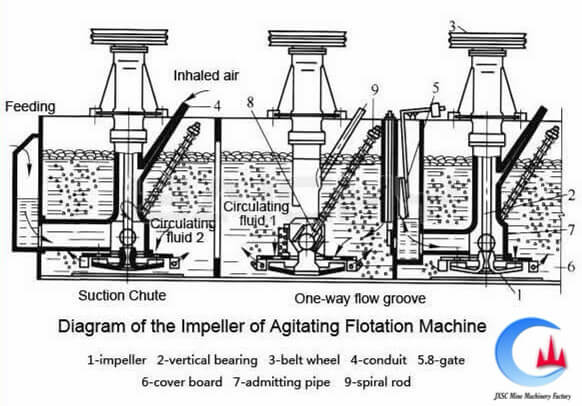

The impeller is rotated by V-belt of motor and produces negative pressure by centrifugal function. Enough air is sucked to mix slurry, and slurry mixes drugs simultaneously.

Mineral sticks on the bubble completely and floats on the surface of the slurry to form mineralized bubble. The useful bubble is scraped out by adjusting the flashboard height and controlling the liquid surface.

Flotation machines For Sale

Types Of flotation machine

There are three main types of JXSC flotation equipment, namely mechanical agitation flotation machines (BF, JJF type), inflatable agitation flotation machines (XCF type, KYF type) and inflatable flotation machines (XJB rod flotation machine).

During the flotation process, the reagents and the ore pulp to be selected are mixed and then put into the flotation equipment. After the stirring and aeration of the flotation machine, the bubbles and the ore particles are contacted, collided, and adhered to achieve the final mineralization. The target minerals float up with the bubbles to the surface of the ore pulp and become a foam layer, which forms the flotation concentrate; it is discharged from the flotation machine by scrapers or gravity. Non-target minerals are retained in the ore pulp area and discharged from the tank.

How to choose a model? Contact us to get flotation equipment prices and details!

why choose JXSC Flotation machine

features & Advantages Of Flotation machine

1. Create a suitable environment for the dynamic collision of bubbles and particles and the static separation of bubbles and particle combinations, which is conducive to the selection of fine particles; simple operation and high degree of automation.

2. It can make the pulp circulation reasonable, minimize the sedimentation of coarse sand, and have low power consumption.

3. The enrichment ratio is large, the recovery rate is high, and the processing capacity is large. It is especially suitable for processing micro-grained particles and is easy to self-control and large-scale.

models & specifications

Model | Volume | Cell size | Impeller Dia. | Impeller speed | Capacity | Power | Singe cell weight |

| m3 | mm | mm | r/min | m3/min | kw | kg |

XJK-3A | 0.35 | 700×700×700 | 300 | 483 | 0.18-0.4 | 2.2/0.55 | 430 |

XJK-4A | 0.62 | 820×900×850 | 350 | 400 | 0.3-0.9 | 3/1.1 | 755 |

XJK-5A | 1.1 | 1100×1100×1000 | 500 | 330 | 0.6-1.6 | 5.5/1.1 | 1416 |

XJK-6A | 2.8 | 1750×1600×1100 | 600 | 280 | 1.5-3.5 | 11/1.1 | 2113 |

XJK-7A | 5.8 | 2200×2200×1200 | 750 | 240 | 3–7 | 22/1.5 | 3400 |

SF-0.37 | 0.37 | 700×700×750 | 296 | 386 | 0.2-0.4 | 1.5/0.55 | 468 |

SF-0.7 | 0.7 | 820×900×950 | 350 | 400 | 0.3-0.9 | 3/1.1 | 805 |

SF-1.2 | 1.2 | 1100×1100×1100 | 450 | 312 | 0.6-1.2 | 5.5/1.1 | 1373 |

SF-2.8 | 2.8 | 1700×1600×1150 | 550 | 268 | 1.5-3.5 | 11/1.5 | 2138 |

SF-4 | 4 | 1850×2050×1200 | 650 | 220 | 2–4 | 15/1.5 | 2582 |

SF-8 | 8 | 2200×2900×1400 | 760 | 191 | 4–8 | 30/1.5 | 4129 |

SF-10 | 10 | 2200×2900×1700 | 760 | 191 | 5–10 | 30/1.5 | 4486 |

SF-16 | 16 | 2850×3800×1700 | 760 | 191 | 5–16 | 30×2/1.5 | 8320 |

SF-20 | 20 | 2850×3800×2000 | 760 | 191 | 5–20 | 30×2/1.5 | 9828 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, no investing)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.