magnetic separators

The principle of magnetic separation is to use magnetic separators to selectively separate magnetic ore from a mixture containing other non-magnetic particles based on the size and magnetic properties of the particles.

Application of magnetic separators

- Magnetic separation of metal minerals: hematite, limonite, siderite, ilmenite, chromite, wolframite, tantalum niobium, tin, iron ore, manganese, coltan;

- Iron removal and purification of non-metallic minerals: feldspar, zircon, quartz, fluorite, spodumene, kaolin, monazite, tourmaline, silica sand, garnet; or recovery of iron from beach sand.

Magnetic separators supplier

JXSC is a professional mining magnetic separation equipment manufacturer with over 38+ years of experience, with a variety of types to choose from, including wet drum type, three-disc dry type, high intensity, flat-plate type, vertical ring high gradient, slurry magnetic separators, etc. However, magnetic separation equipment can effectively removes unwanted ferrous contaminants from mineral. Improves the recovery rate of high-purity and quality concentrate ore in mining and mineral processing, providing an efficient and environmentally friendly solution for separating ferrous from non-ferrous materials. JXSC magnetic separation machines can be used in laboratory, industry or mining and we supports customize them to meet specific needs. Contact us to get factory direct price!

Types of magnetic separation equipment

Magnetic separators for sale

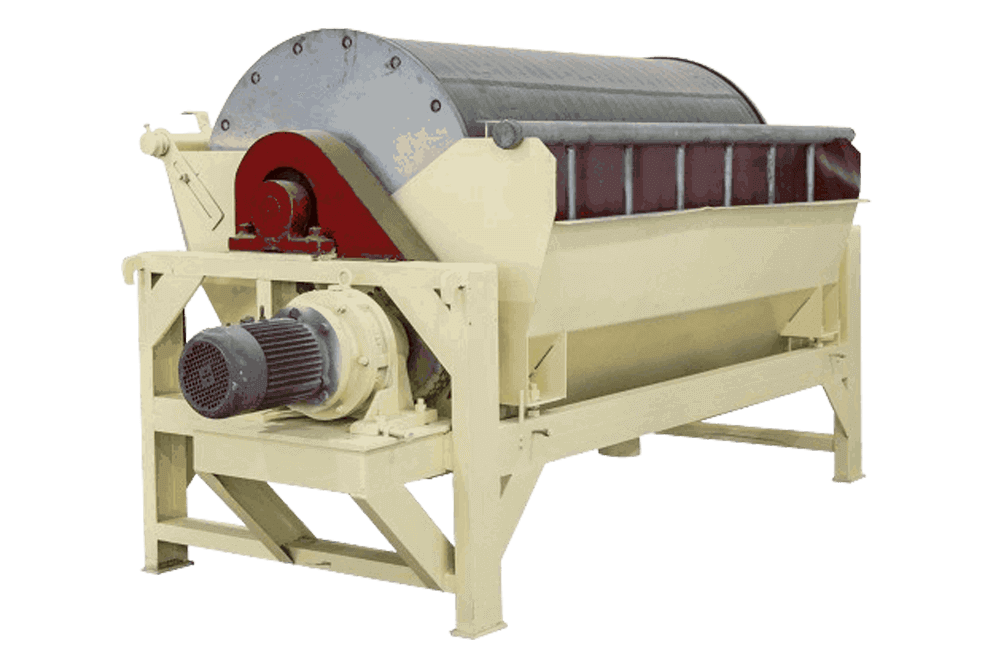

Introduction

Capacity: 0.5-180 t/h

Wet drum magnetic separator is a widely used magnetic separation equipment for iron, coltan, manganese, tin ore or chrome mineral processing. Separating magnetic ore from 3~0mm fine particle mixture. The drum magnetic separator is mainly used for iron removal and purification in non-metallic mineral sand separation plant, such as quartz sand, feldspar, beach sand, monazite, etc.

Features

- The application range is particularly wide, with permanent magnets, continuous feeding and discharging and short downtime.

- The high-strength and high-reliability mechanical structure ensures the normal operation of the machine in various harsh environments.

- According to users’ needs, various types of magnetic drum separator with different surface strengths such as downstream, semi-countercurrent, and countercurrent types can be provided.

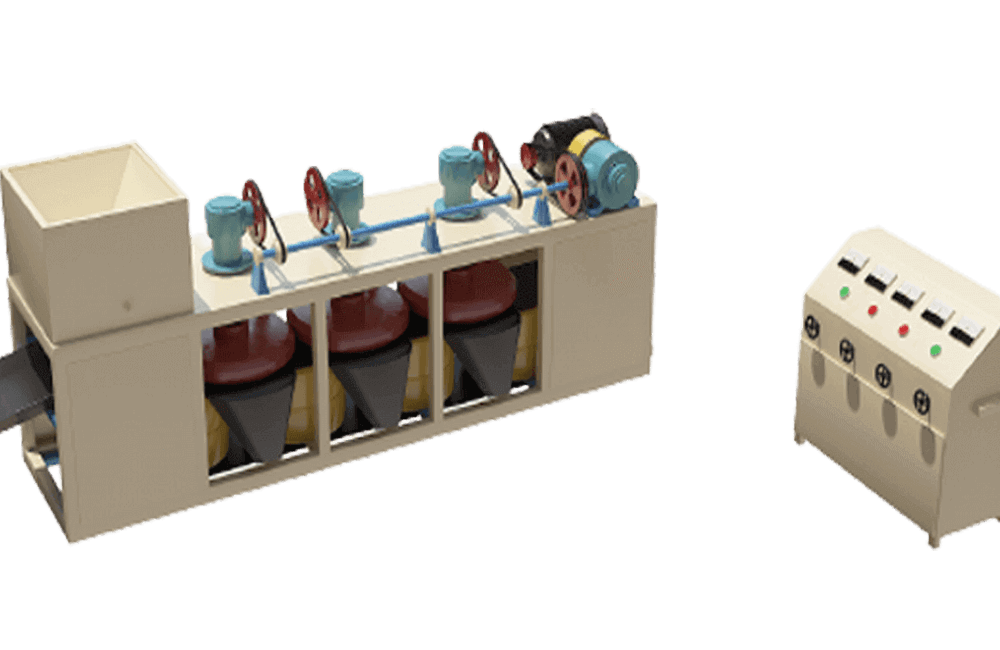

Introduction

Capacity: 100-500 Kg/h

The three-disc magnetic separator is mainly used to dryly separate granular minerals, such as titanium ore, zircon, rutile, feldspar, quartz, tungsten-tin ore and coltan magnetic separation process. The dry magnetic separation equipment is an iron removal machine for metallic minerals or non-metallic ore. It’s also the separation and purification machine of ore in mineral processing.

Features

- The induction distance between the disks at all levels and the selected ore particles can be adjusted to obtain different magnetic field induction intensities;

- It can separate strong magnetic, weak magnetic, non-magnetic and other minerals at one time;

- The three-disc type machine can be adapted to dry operation in water-deficient mining areas.

Introduction

Capacity: 0.2-9 t/h

The high intensity magnetic separator (multi-roller magnetic separators) is mainly suitable for dry sorting large-grained, coarse-grained ferromagnetic ores and fine-grained weakly magnetic ores. Including magnetite, pyrrhotite, limonite, hematite, manganese ore, ilmenite and other ore magnetic separation. Single, double, or multi-roller magnetic separators are optional and suppots customized.

Features

- Adopt multi-layer induction magnetic pole design, large gradient, high intensity, low power consumption and good sorting effect;

- Continuous automatic removal of iron debris, adjustable feed rate control, the magnetic field strength of each layer is customizable;

- Magnetic rollers can be assembled in blocks, and the diameter and length of the rollers can be selected according to the requirements of the ratio of magnetic susceptibility coefficient, particle size and processing capacity of the sorted minerals.

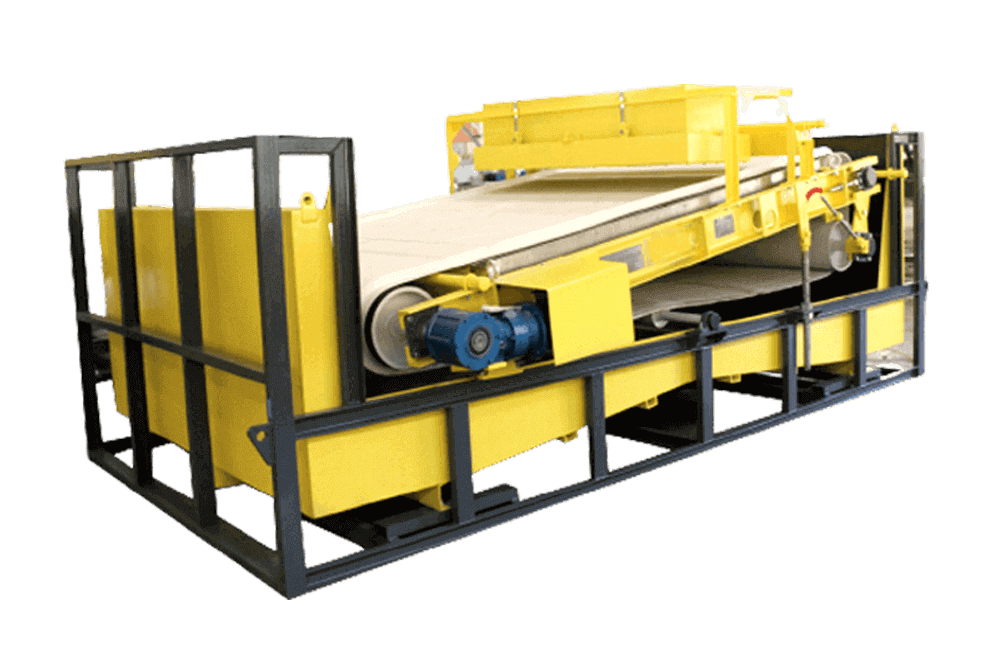

Introduction

Capacity: 8-35 t/h

The wet plate magnetic separator is lab or mining magnetic separation equipment for iron impurities and purification of non-metallic minerals. Separation of limonite, hematite, ilmenite, garnet, carborundum and fine-grained weak magnetic minerals, the wet magnetic separator mainly used for iron removal in quartz sand, the effect is particularly obvious.

Features

- It has a very wide pole-focusing face with many poles. It has a very high magnetic induction;

- The belt is made of high-quality composite materials, with long service life and obvious iron removal effect;

- Driven by a small frequency motor, the unique water system controllable design saves water and energy.

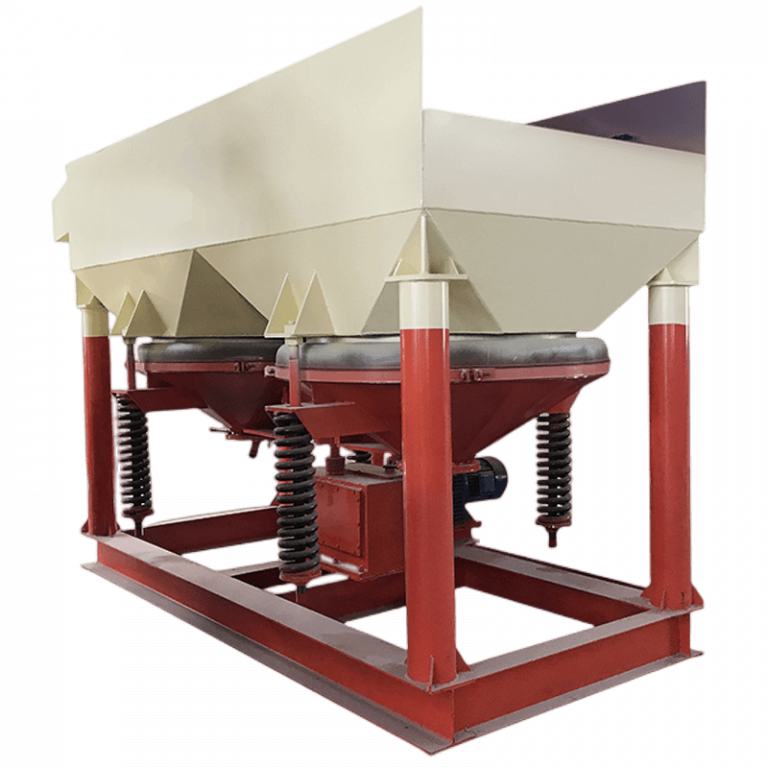

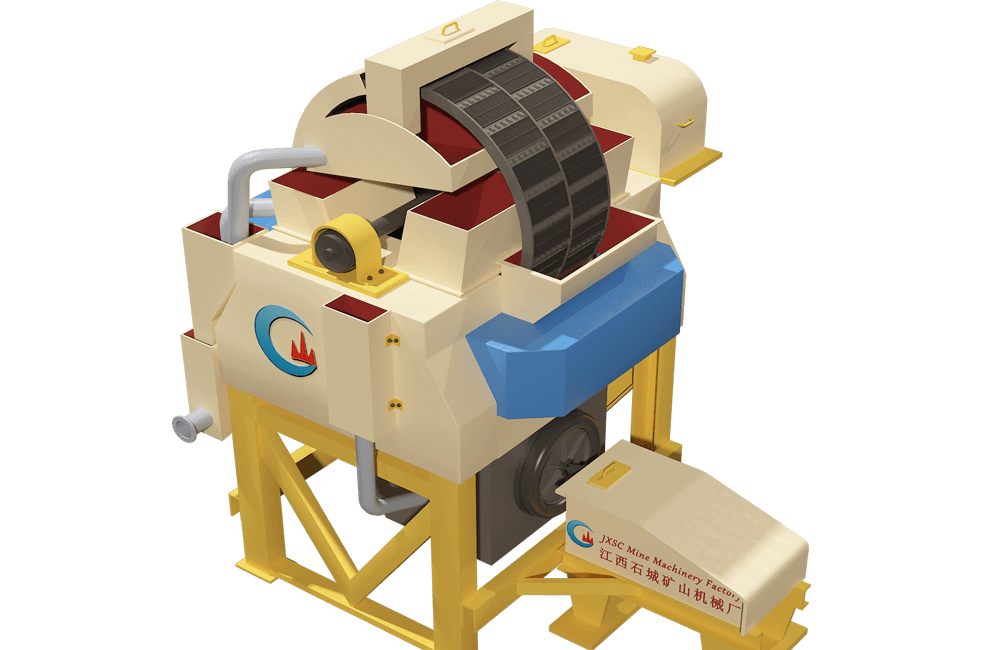

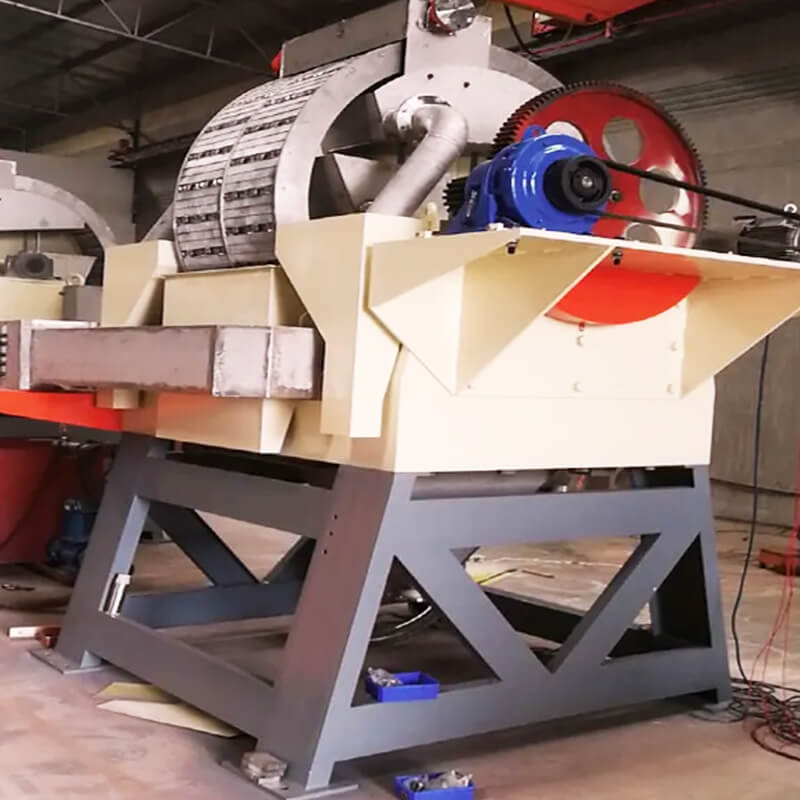

Introduction

Vertical ring pulsating high gradient magnetic separator, or vibrating high intensity strong magnetic separation machine, wet high intensity magnetic separator (WHIMS). It is a magnetic separation equipment with advanced technology and good performance. The high gradient magnetic separator mainly uses the comprehensive effect of vertical ring rotation, pulsating mineral separation and high frequency vibrator to wet separate various weak magnetic materials.

Features

- It adopts the operation mode of vertical circulation and repeated washing of concentrate, which is not easily blocked and has a good separation index;

- This high gradient magnetic separator has strong magnetic force and can effectively remove weak magnetic impurities in non-metallic ores;

- The magnetic field gradient is large and adjustable, with high intensity, high grade of finished concentrate, and recovery efficiency up to 98%.

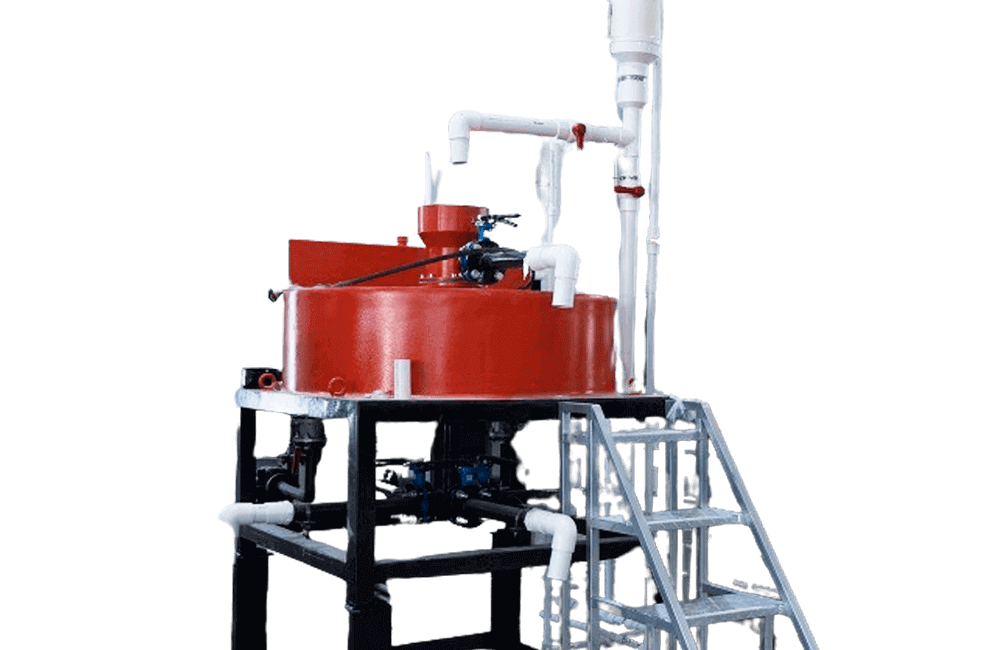

Introduction

The slurry magnetic separator is a wet high-intensity electromagnetic separation equipment. It has a strong adsorption effect on low-content weakly magnetic and fine impurities, and the iron removal effect is very impressive. It automatically absorbs and removes iron and has a strong collection capacity. JXSC slurry magnetic separators can automatically and continuously purify or concentrate weakly magnetic materials. It is often used to remove impurities such as iron and titanium in kaolin beneficiation.

Features

- High magnetic field, uniform magnetic field distribution, high gradient, and high efficiency in iron separation;

- It adopts a safe and reliable water-oil dual cooling circulation system to extend the service life of the machine;

- The slurry magnetic separator uses fully automated control during the iron removal and discharge process, saving time and effort.

Recommended equipment

magnetic separation Solutions

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.