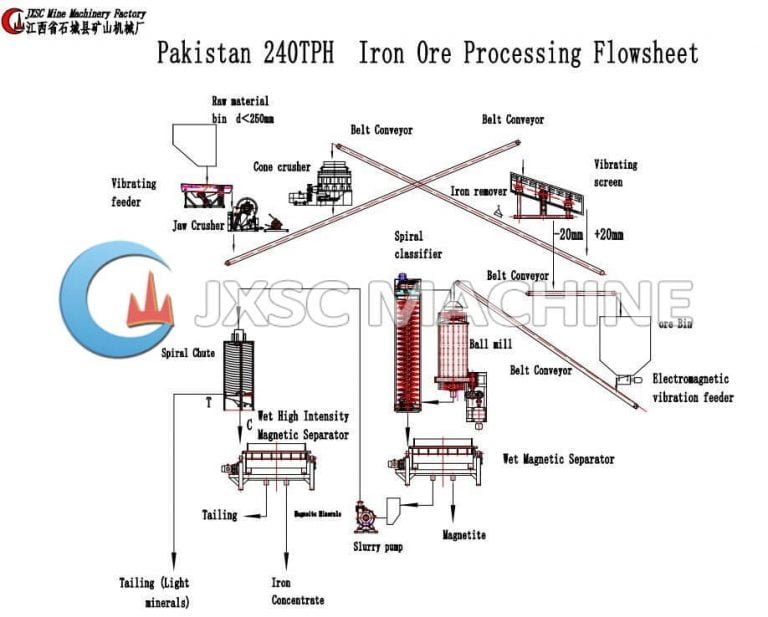

240TPH Iron Ore Processing Plant in Pakistan

We guarantee the high quality machine in the mineral processing industry, established in 38 years of experience

minerals

rock iron ore, contains no clay. grade 42-57%

capacity

240TPH in Pakistan

feed size

0-250mm

Customer's request

iron grade to 65%, final product size 12-18mm

| Constituent | Fe | Al2O3 | SiO2 | MgO | CaO | TiO | CuO | S |

| % | 43-57 | 2.8-5 | 15-25 | 0.5-2 | 0.5-2 | 0.1-0.5 | 0.1-1 | 0.1-1 |

process flow

1. Crushing & Screening: jaw crusher, cone crusher, vibrating screen

Vibrating feeder evenly feeds the jaw crusher. jaw crusher crush big rock, Then transport it to the vibrating screen with a belt conveyor, and screen out two kinds of materials, +20MM, 0-20mm. The +20MM material is conveyed to the cone crusher by a belt conveyor with an iron remover for secondary crushing to reach the material less than 20MM.

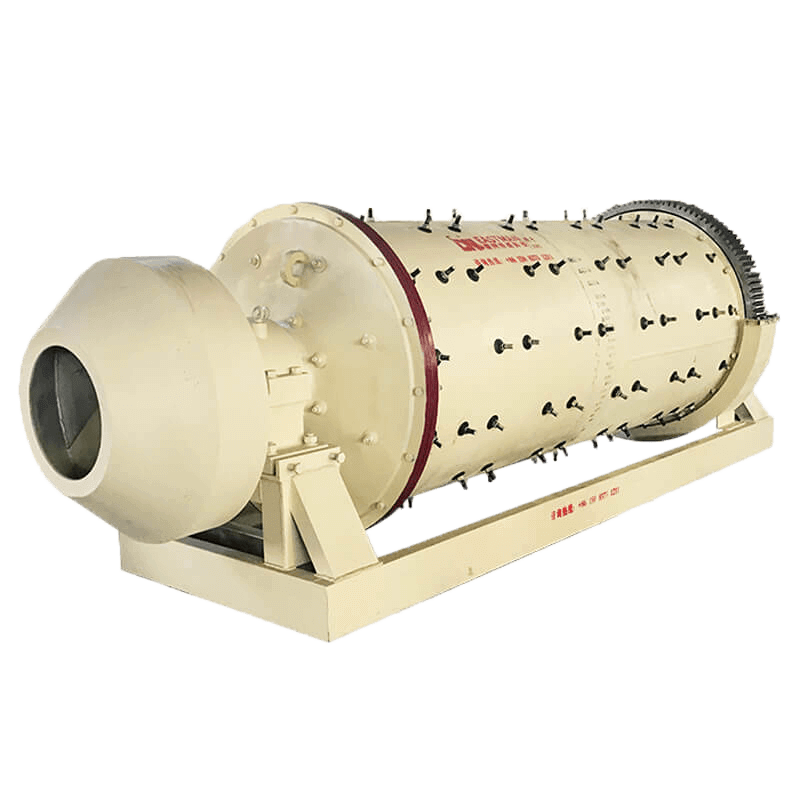

2. Grinding: ball mill, spiral classifier

-20MM materials are transported to the ore silo, conveyed to the ball mill by electromagnetic vibrating feeder, and ground to below 200 mesh together with the classifier.

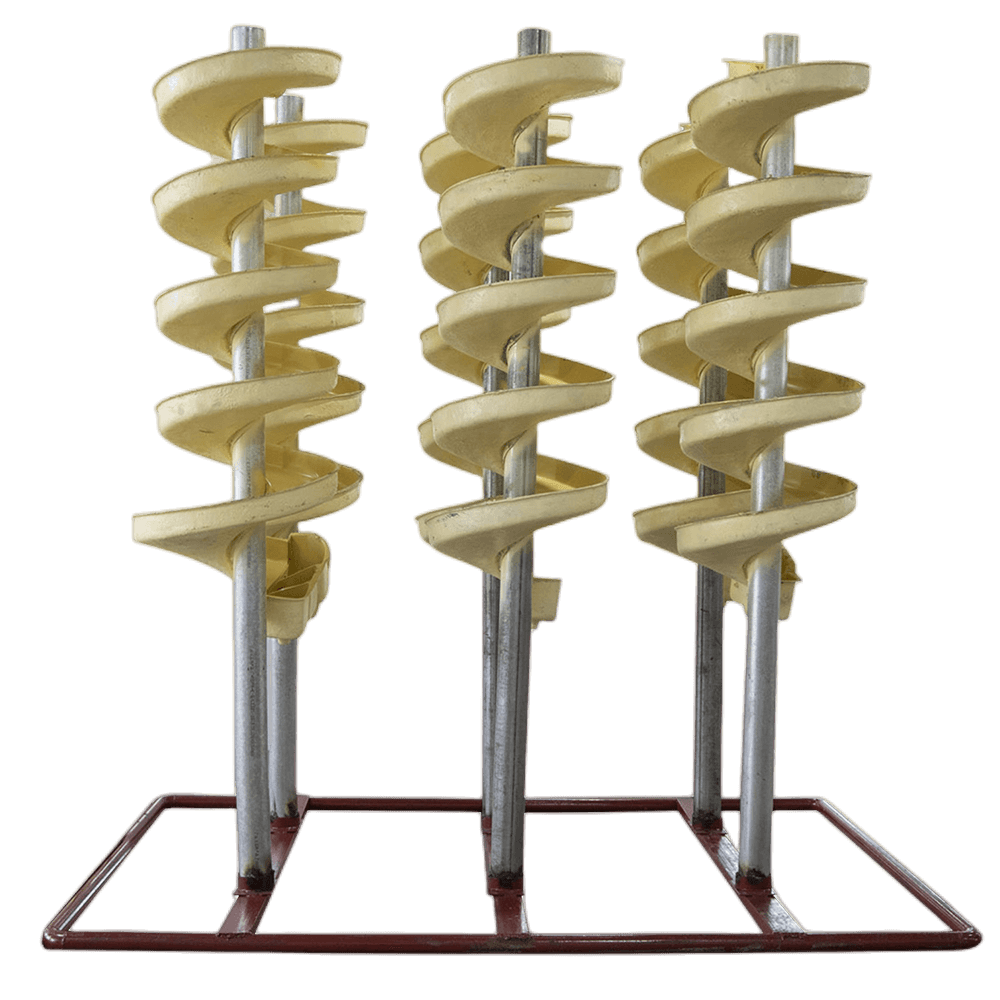

3. Magnetic separation: wet high intensity magnetic separator

Then the materials that meet the specifications enter the wet magnetic separator to separate the manganese iron ore. The rest of the material is pumped to the spiral chute with sand, and then enters the magnetic separator to separate the tailings and iron ore concentrate.

Iron Ore Processing Plant Solutions & Flow Design

Main equipment

| Equipment name | Model | Power(kw) | Qty |

| Vibrating feeder | 590*1100 | 22 | 1 |

| Cone crusher | 1400 | 220 | 1 |

| Vibrating screen | 2160 | 22 | 1 |

| Belt conveyor | 800*20m | 11 | 1 |

| Eletro-vibrating feeder | GZ8 | / | 1 |

| Ball mill | 2736 | 400 | 10 |

| Spiral classifier | 2000 | 15kw | 10 |

| Magnatic separator | 1230-1200GS | 11kw | 2 |

| Slurry pump | 10/8 | 110kw | 1 |

| Spiral chute | 1200 | / | 90 |

| Magnetic separator | 1230-9000GS | 22 | 2 |

Notes: in order to reduce the investment in the early stage of equipment, belt conveyors and hopper are made locally according to the site conditions.

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.