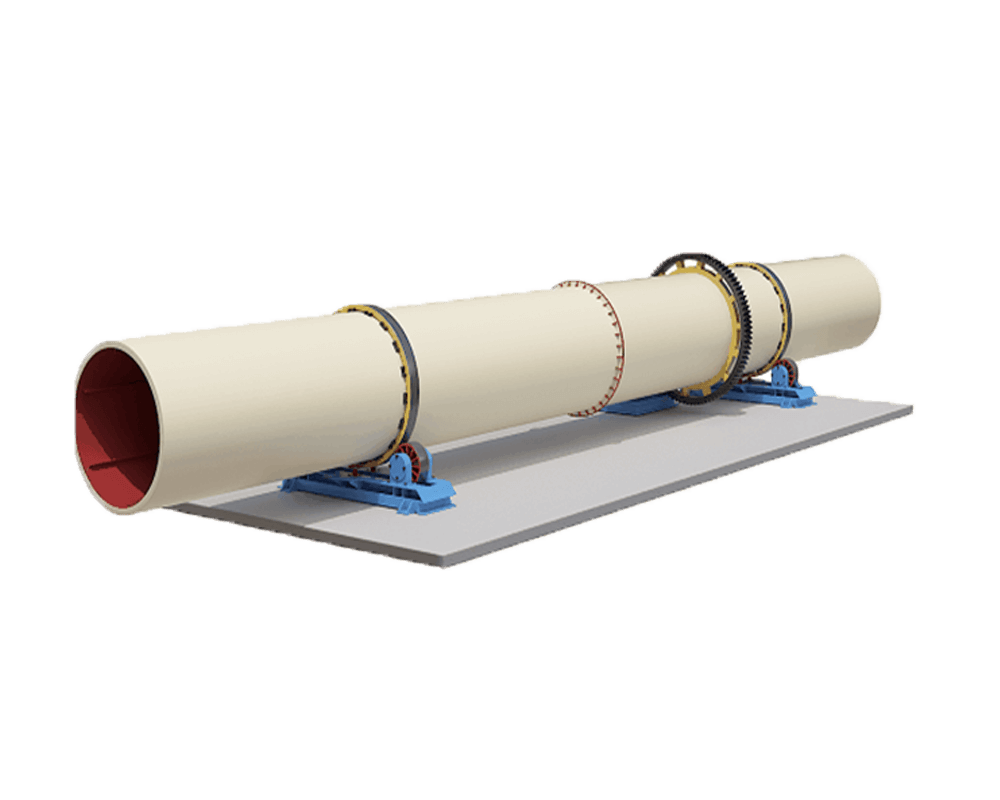

Rotary Dryer

Capacity: 0.8~40 tons/hour

Suitable materials: drying powder, lump, granular materials such as coal slime, ore powder, slag, sludge, clay, iron ore, pyrrhotite, hematite, limonite, gold, molybdenum ore, limestone, river sand, quartz sand, shell powder, fly ash, fluorite, etc.

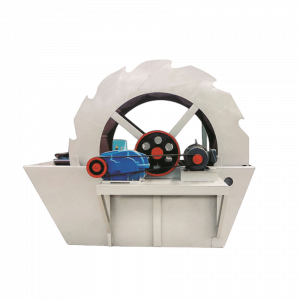

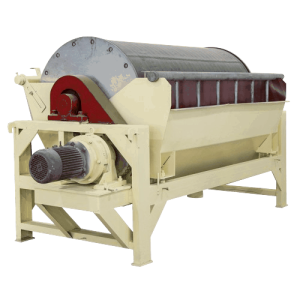

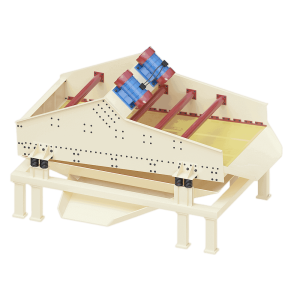

Products display

Introduction of plate filter press

Rotary dryer is also called long drum dryer or drum dryer. It is the most common kind of dryer equipment in mining equipment. It has high production efficiency, convenient operation and easy maintenance. The dryer has a reasonable structure, excellent manufacturing process, high efficiency, energy saving, and convenient operation.

JXSC rotary dryers use reasonable operating parameters; the coal consumption and electricity consumption are reduced by more than 10-15% compared with the general dryer, and the output when the machine is increased by more than 10-15%.

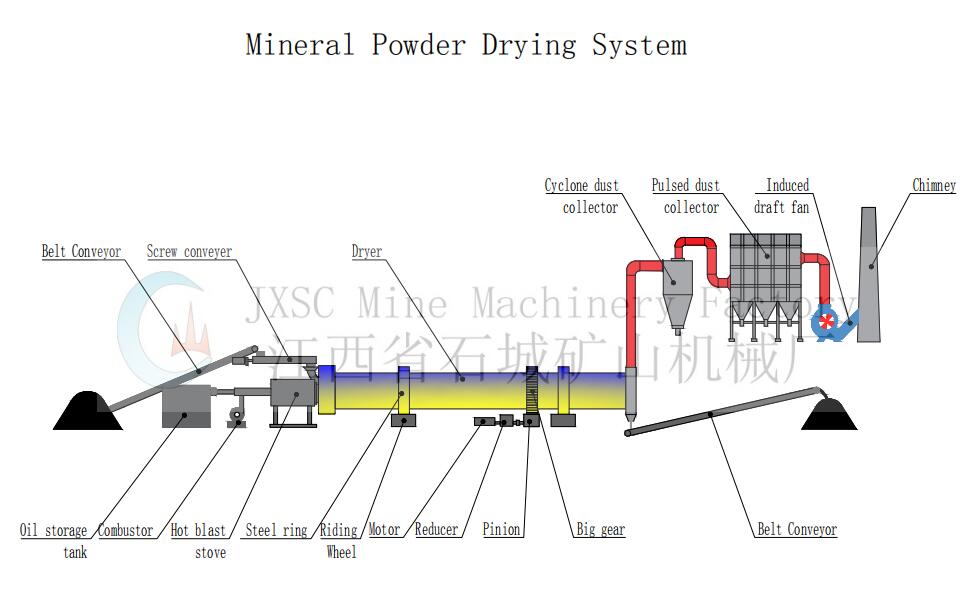

working principle of rotary dryer

The rotating drum of the dryer is a slightly inclined and rotatable cylinder. Wet materials enter from the upper part of one end and dry materials are collected from the lower part of the other end. Hot air enters from the feeding end of the discharging end and exits from the upper part of the other end. The barrel is equipped with a forward copy board so that the material is continuously picked up and sprinkled during the rotation of the barrel so that it is fully contacted with the hot airflow to improve the drying efficiency and move the material forward. The heat source of dry materials is generally hot air, high-temperature flue gas, etc. It can be selected according to the nature and quality requirements of materials.

Why Choose JXSC rotary dryer

Features & advantages Of Rotary dryer

1. Large drying intensity, short drying time and large effective drying area;

2. The structure is simple, the area is small, and it is easy to construct and maintain;

3. Large processing capacity, thermal efficiency up to 60%;

4. The drum dryer adopts “aligning roller device”, which greatly reduces wear and power loss

models & specifications

Model(mm) | Rotation Speed(r/min) | Feeding Size(mm) | Angle of Inclination(%) | Intake humidity(℃) | Output(t/h) |

|

φ800×800 | 3-8 | ≤20 | 3-8 | ≤700 | 0.8-2 | 3.5 |

φ800×10000 | 3-8 | ≤20 | 3-8 | ≤700 | 0.8-2.5 | 4.5 |

φ1000×10000 | 3-8 | ≤20 | 3-8 | ≤700 | 1-3.5 | 5.6 |

φ1200×10000 | 3-8 | ≤20 | 3-8 | ≤700 | 1.8-5 | 14.5 |

φ1200×12000 | 3-8 | ≤20 | 3-8 | ≤700 | 2-6 | 14.8 |

φ1500×12000 | 2-6 | ≤20 | 3-8 | ≤800 | 3.5-9 | 17.8 |

φ1800×12000 | 1.5-6 | ≤20 | 3-8 | ≤800 | 5-12 | 25 |

φ2200×12000 | 1.5-6 | ≤20 | 3-8 | ≤800 | 6-15 | 33 |

φ2200×18000 | 1.5-6 | ≤20 | 3-8 | ≤800 | 10-18 | 53.8 |

φ2200×20000 | 1.5-6 | ≤20 | 3-8 | ≤800 | 12-20 | 56 |

φ2400×20000 | 1.5-5 | ≤20 | 3-8 | ≤800 | 18-36 | 60 |

φ3000×20000 | 1.5-5 | ≤20 | 3-8 | ≤800 | 25-35 | 78 |

φ3000×25000 | 1.5-5 | ≤20 | 3-8 | ≤800 | 32-40 | 104.9 |

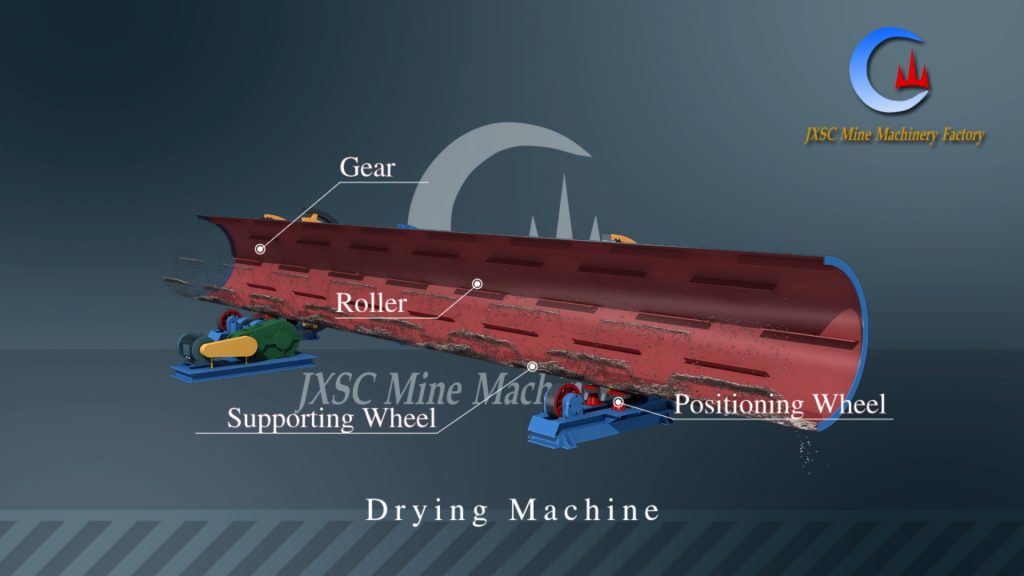

The drum dryer equipment is a kind of drying equipment that can dry a variety of materials and it’s structure is simple and reliable.

This dryer machine is mainly composed of:

★Rotary body: a rotating cylinder that is slightly inclined to the horizontal line, the wet material rotates with the cylinder in the cylinder, and the wet material flows to the lower end under the action of gravity and is dried and discharged;

★Lifting plate: The material rotates along with the rotating cylinder in the slewing body. During the full contact with the hot air flow, it is continuously sprayed by the lifting plate, so that the wet material forms a uniform curtain in the cylinder body, and the hot air flow Full contact for heat exchange. In order to achieve the purpose of further drying;

★Rotating device: The rotating device drives the rotating drum of the rotating drum dryer to make the wet material fully contact with the inner wall of the drum, and then conduct heat exchange to achieve the purpose of sufficient drying;

★Feeding box: The material enters the rotating body from the feeding box.

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.