lithium processing plant

Lithium beneficiation processing plant includes crushing, grinding, gravity separation, flotation, magnetic separation and combined process.

According to the nature of lithium ore(spodumene, lepidolite, lithium feldspar), JXSC supports custom lithium processing plants and equipment to obtain the best separation index.

Lithium beneficiation process

Different lithium ores have different properties, and the lithium content and mineral composition in minerals are different, so lithium ore beneficiation methods are also different.

The lithium beneficiation process is mainly used for three lithium-containing minerals processing: spodumene, lithium feldspar, lepidolite.

| Minerals | Lithium content/% | Density/(g⋅cm-³) | Hardness |

| Spodumene | 3.7 | 3.1~3.2 | 6~7 |

| Lepidolite | 1.39~3.6 | 2.8~3.3 | 2.5~4 |

| Lithium feldspar | 1.6~2.7 | 2.4 | 6~6.5 |

Lithium ore process

- Gravity separation: 1). When the density difference between spodumene and gangue ore is more than 0.2-0.5g/cm3, the gravity separation method is used, especially the spodumene with coarse particle size. Commonly used shaking tables, jigs and other equipment. 2). When the density difference is less than 0.2~0.5g/cm, the ore is mixed with dense medium (suspension made by mixing ferrosilicon powder and water), and enters the dense medium cyclone for separation and separation.

- Flotation separation: The main lithium minerals can be sorted by flotation method. Especially for lithium ore that exists in the form of fine particles disseminated, the recovery rate is high and the process is simple.

- Magnetic Separation: An auxiliary method used to remove iron impurities from concentrates. Since iron lepidolite and spodumene containing iron have weak magnetic properties, they can be sorted by strong magnetic methods to improve the product quality of spodumene.

- Flotation-Magnetic Separation Combined Beneficiation: When the flotation-magnetic separation combined process is applied to the lithium concentrate obtained after the flotation method contains more iron, it is to obtain low-iron spodumene.

- Gravity-flotation-magnetic separation combined beneficiation: For lithium ore containing tantalum and niobium minerals, the combined process of gravity separation + flotation is generally used for processing. The ore after gravity separation can enter flotation stage after desliming treatment. The concentrate after flotation is sent to the magnetic separator to remove iron, improve the quality of concentrate.

Lithium ore beneficiation is mainly based on flotation process. It is also often combined with gravity separation, magnetic separation and other combined processes. Contact us to get more lithium ore process flow and equipment details!

lithium processing plant

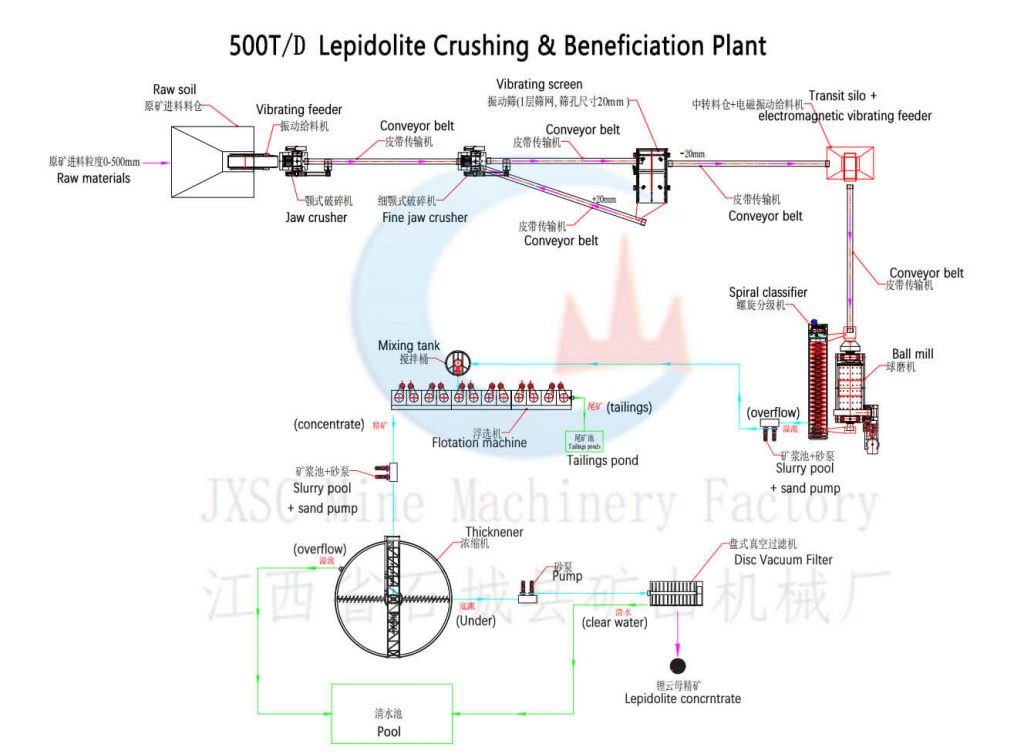

1. Lepidolite flotation plant

1. Crushing & screening: The hopper + vibrating feeder automatically feeds the 0-500mm material into the jaw crusher. Jaw crushers are used to break large stones into small pieces. Then, the material enters the fine jaw crusher to make the stone into fine sand. The vibrating screen has a layer of screen mesh, which is used to screen materials more than 20mm and return to the fine jaw crusher, and screen materials with 0-20mm to the storage bin.

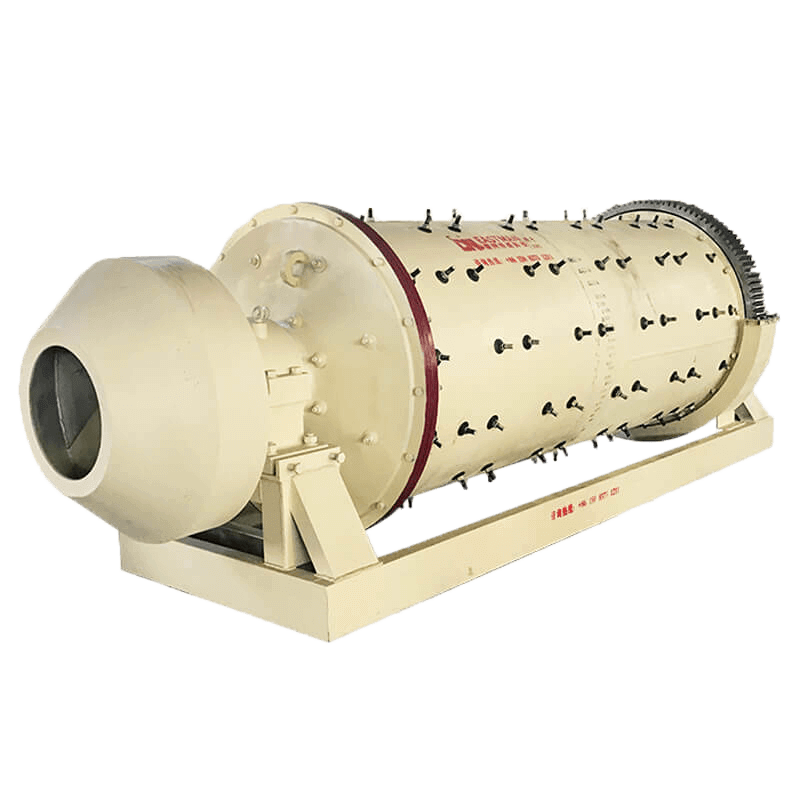

2. Grinding: The storage bin + electromagnetic feeder automatically feeds the material into the ball mill and grinds the fine sand to 0-1mm. Then the ball mill is combined with the spiral classifier to form a closed-circuit ring mill to ensure that the final product’s particle size is 0-0.074mm.

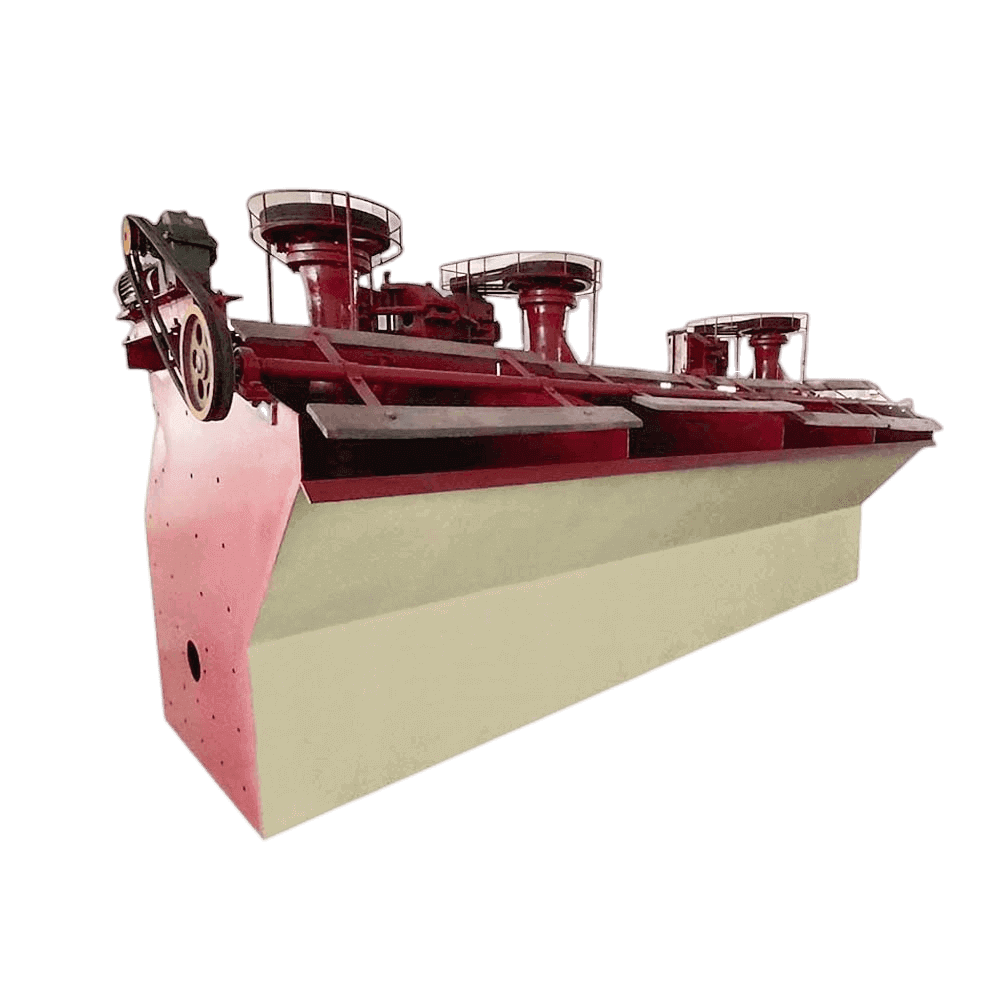

3. Flotation: The overflow of the spiral classifier enters the slurry tank and is transported to the flotation machine by the sand pump. Chemicals are added to the flotation machine to extract lepidolite concentrate.

4. Concentration: The concentrate of the flotation machine enters the slurry pool and is then sent to the thickener by the sand pump. It overflows into the clear water pool, which can save water resources and recycle. Then the underflow of the concentrator is sent into the disc vacuum filter with a sand pump to obtain dry lepidolite concentrate. Contact us to design lepidolite ore processing plant flow and equipment!

2. Spodumene processing plant

- Crushing & screening: In the crushing and screening stage of lithium ore, a three-stage and one closed-circuit crushing and screening process, or a two-stage and one closed-circuit crushing and screening process can be adopted. Specifically, it is necessary to refer to the particle size of the raw ore and equip a reasonable lithium ore crushing process.

- Grinding & Classifying: In order to ensure that lithium minerals are fully dissociated from gangue mineral monomers, a closed-circuit grinding and classifying process can be adopted, using ball mill + classifying machine. According to the ore properties of different lithium ores, some lithium ores may need to be deslimed after the grinding stage.

- Benefciation stage: Lithium ore usually has many different associated minerals. It is mainly based on flotation, often combined with gravity separation, magnetic separation and other combined processes for lithium benefciation.

- Concentrate dewatering: In order to obtain high-quality lithium concentrate, the lithium concentrate product is concentrated and dewatering. Contact us to customized spodumene ore processing plant details and equipment latest price!

Related equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.