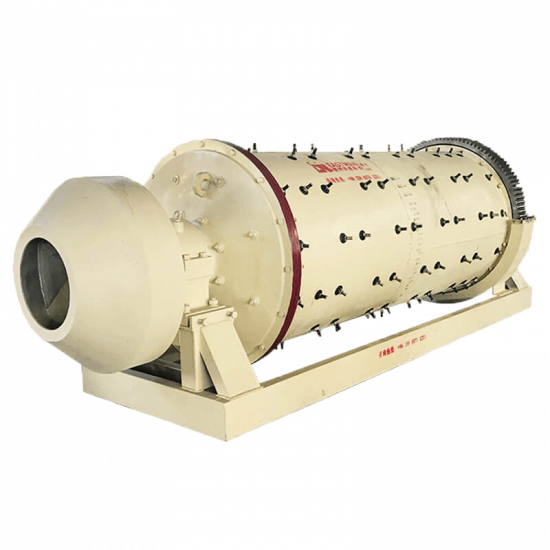

Ball Mill

Capacity: 0.4-150 t/h

Feeding size: ≤20-25 mm

Output size: 0.074-0.6 mm

Application: Gold, rock, sand, cement, quartz, silica sand etc., as well as copper, lead, zinc, chrome and other ores for grinding

Products display

Overview

Introduction: The ball mill is a tumbling mill that uses steel balls as grinding media. Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or large-scale ore beneficiation plant.

- Dry grinding: suitable for materials that react with water, such as building stones such as cement and marble. Due to the lack of water resources in some arid areas, dry grinding can also be used in order to save water.

- Wet grinding: suitable for most materials, various metal ores and non-metal ores. Common ones include grinding gold, copper, iron ore, molybdenum ore, feldspar ore, lithium, chrome, fluorite ore, etc.

Types: Mining ball mills are divided into two categories, Overflow ball mills: center discharge ball mills; Lattice type ball mills: Peripheral row ore type ball mills.

Batch small ball mill: control the particle size of the material by adjusting the grinding time.

Advantages

- The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, non-metallic ores, cement clinker, etc.

- It has a highly automated control system, including automatic start and stop, adjustment of grinding speed and addition of grinding media to improve the convenience of operation;

- Our grinding equipment has large processing capacity and can meet the high output needs of mining and metallurgical enterprises.

- JXSC ball mill is designed to be energy-saving and environmentally friendly. It often forms a closed-circuit ring grinding device with a spiral classifier to produce powder with a relatively uniform particle size.

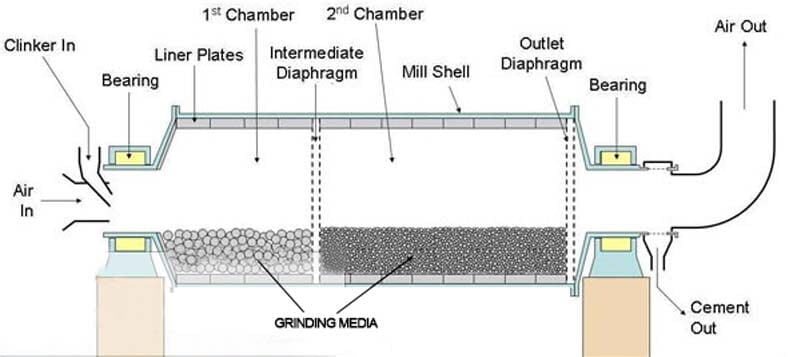

working principle of ball mill

Materials are fed into the barrel of the ball mill through the hollow shaft. A motor drives the barrel of the ball mill to rotate. The materials and media in the barrel spin and move at a certain speed, including gravity, centrifugal force, and friction. When the grinding medium and the cylinder reach a certain height and its weight is greater than the centrifugal force, it will break away from the inner wall of the cylinder and fall or roll down. Since the gravitational potential energy is converted into kinetic energy when falling, the steel ball will eventually collide with the ore at a certain speed, and the impact force will break the ore. The crushed qualified materials are discharged through the ore discharge port.

models & specifications

Model | Drum size(m) | Rotation speed | Ball load(t) | Feeding size(mm) | Output size(mm) | Capacity(t/h) | Motor power(kw) | Weight(t) |

MQZ0918 | 0.9*1.8 | 38.8 | 1.92 | ≤20 | 0.074-0.6 | 0.4-2.14 | 22 | 5.34 |

MQZ0930 | 0.9*3.0 | 36 | 2.7 | ≤20 | 0.074-0.6 | 1.1-3.5 | 22 | 6.98 |

MQZ1224 | 1.2*2.4 | 31 | 4.8 | ≤20 | 0.074-0.6 | 0.4-6.8 | 37 | 13.43 |

MQZ 1245 | 1.2*4.5 | 31 | 5.2 | ≤20 | 0.074-0.4 | 1.6-12 | 75 | 17.4 |

MQZ 1530 | 1.5*3.0 | 27.5 | 8.1 | ≤25 | 0.074-0.4 | 2.9-16.5 | 80 | 18.6 |

MQZ 1557 | 1.5*5.7 | 29.2 | 15 | ≤25 | 0.074-0.4 | 4.1-25 | 130 | 24.54 |

MQZ 1836 | 1.8*3.6 | 23.9 | 11 | ≤25 | 0.074-0.4 | 8-40 | 155 | 33 |

MQZ2136 | 3.1*3.6 | 23.8 | 27 | ≤25 | 0.074-0.4 | 8-61 | 210 | 46.8 |

MQZ2436 | 2.4*3.6 | 22 | 28 | ≤25 | 0.074-0.4 | 7-95 | 240 | 73 |

MQZ2465 | 2.4*6.5 | 22 | 36 | ≤25 | 0.074-0.4 | 7-110 | 310 | 76 |

MQZ2736 | 2.7*3.6 | 21.9 | 39 | ≤25 | 0.074-0.4 | 13-145 | 400 | 77 |

MQZ2740 | 2.7*4.0 | 21.9 | 43 | ≤25 | 0.074-0.4 | 13-150 | 400 | 91 |

MQZ3060 | 3.0*6.0 | 19 | 70 | ≤25 | 0.074-0.4 | 100-150 | 800 | 155 |

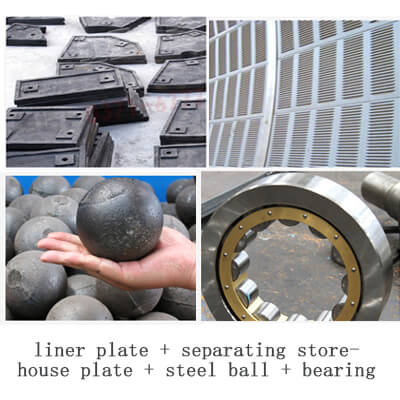

The ball mill includes motor, reducer, slow drive, power distribution control cabinet, feeding device, main bearing, rotary part, discharging device, transmission part, lubrication system (mainly including high-pressure pump station and low-pressure thin oil station) and other parts. The main working part of the ball mill is a rotary cylinder mounted on two large bearings and placed horizontally. The cylinder body is divided into several compartments by a partition plate, and a certain shape and size of grinding body is installed in each compartment. The grinding bodies are generally steel balls, steel forgings, steel rods, pebbles, gravel and porcelain balls. In order to prevent the barrel from being worn, a liner is installed on the wall of the barrel. The length of a cylindrical shell is usually 1–1.5 times the diameter of the shell.

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.