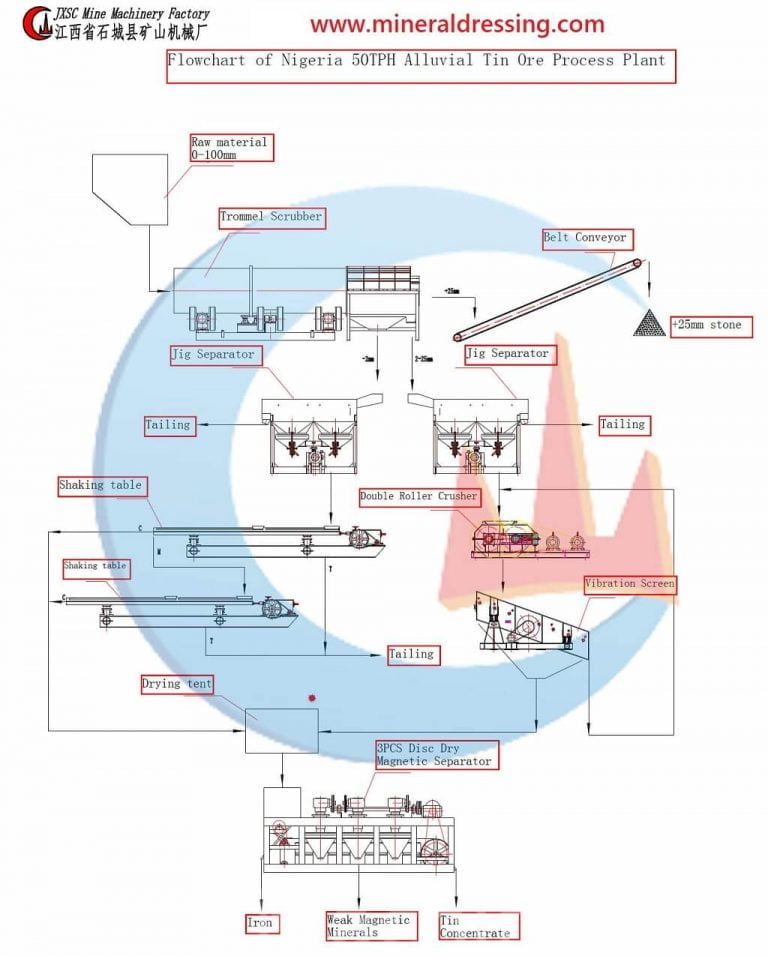

50TPH Alluvial Tin Process Plant In Nigeria

We guarantee the high quality machine in the mineral processing industry, established in 38 years of experience

minerals

Alluvial tin ore, and magnetite, contains clay

capacity

50TPH in Nigeria

feed size

Raw material 0-100mm, tin ore size 0-25mm

Customer's request

Recover tin and magnetite as much as possible

process flow

1. Ore washing: trommel scrubber

This step is aimed at the raw materials with large mud content and strong cementation, such raw materials must be washed and deslimed before being crushed.

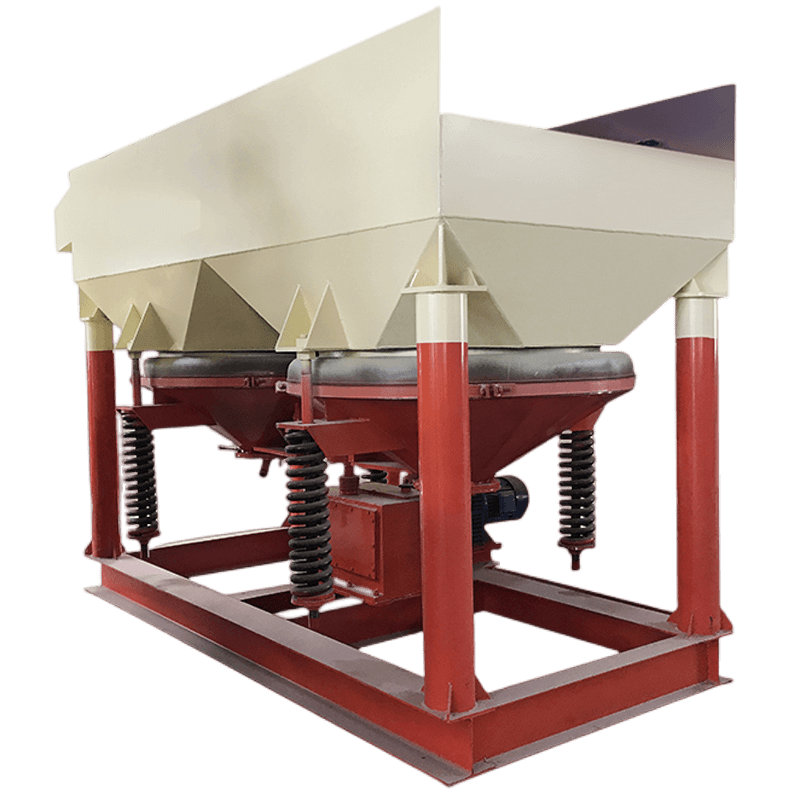

2. Gravity separation: jig, shaking table

After crushing and screening, it will enter the pre-selection stage. -2mm materials enter jig separator to separate, then directly enter the shaking tables.

3. Crushing & Screening: roller crusher, vibrating screen

2-25mm materials enter another jig to separating, then crushed by roller crusher. Use roller crusher to crush raw ore into ore with particle size below 2mm. Then it is divided into two grades by a vibrating screen.

4. Magnetic separation: three disc magnetic separator

The ore selects qualified tin concentrate by magnetic separator.

Tin Processing Plant Solutions & Flow Design

Main equipment

| Equipment name | Model | Power(kw) | Qty |

| Trommel scubber | 1500*4500+2000 | 11 | 2 |

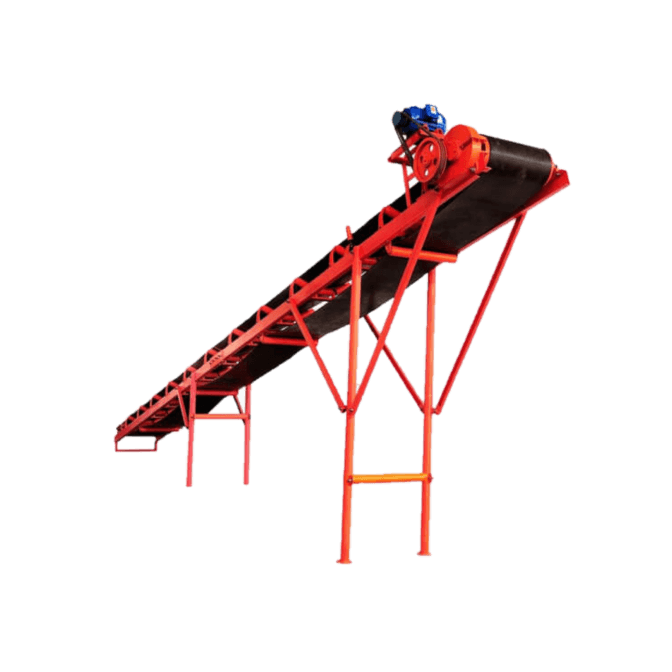

| Belt conveyor | 650*12m | / | 1 |

| Jig separator | JT2-2 | 3 | 2 |

| Vibrating screen | 1224 | 3 | 1 |

| Shaker table | 6s | 1.1 | 1 |

| Roller crusher | / | / | 1 |

Notes: in order to reduce the investment in the early stage of equipment, belt conveyors and hopper are made locally according to the site conditions.

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.