5TPH Tungsten Processing Plant in Mongolia

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

minerals

Wolframite, raw ore 2-5%

capacity

4-5TPH Mongolia

feed size

0-150mm, wolframite size <3mm

Customer's request

grade to 65%

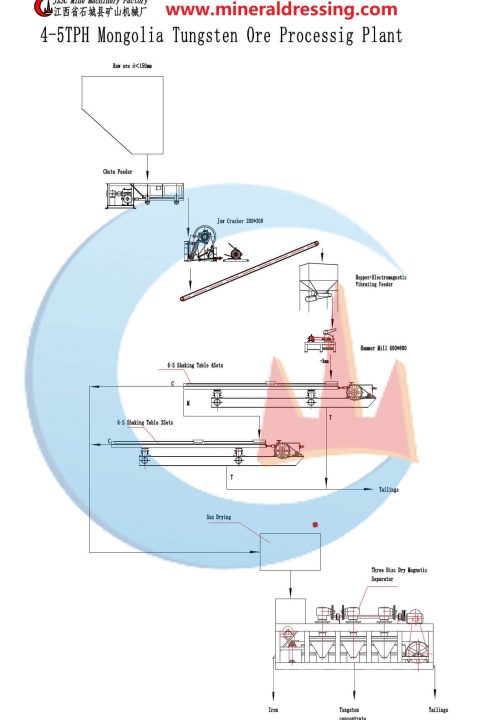

process flow

5TPH Tungsten Processing Plant

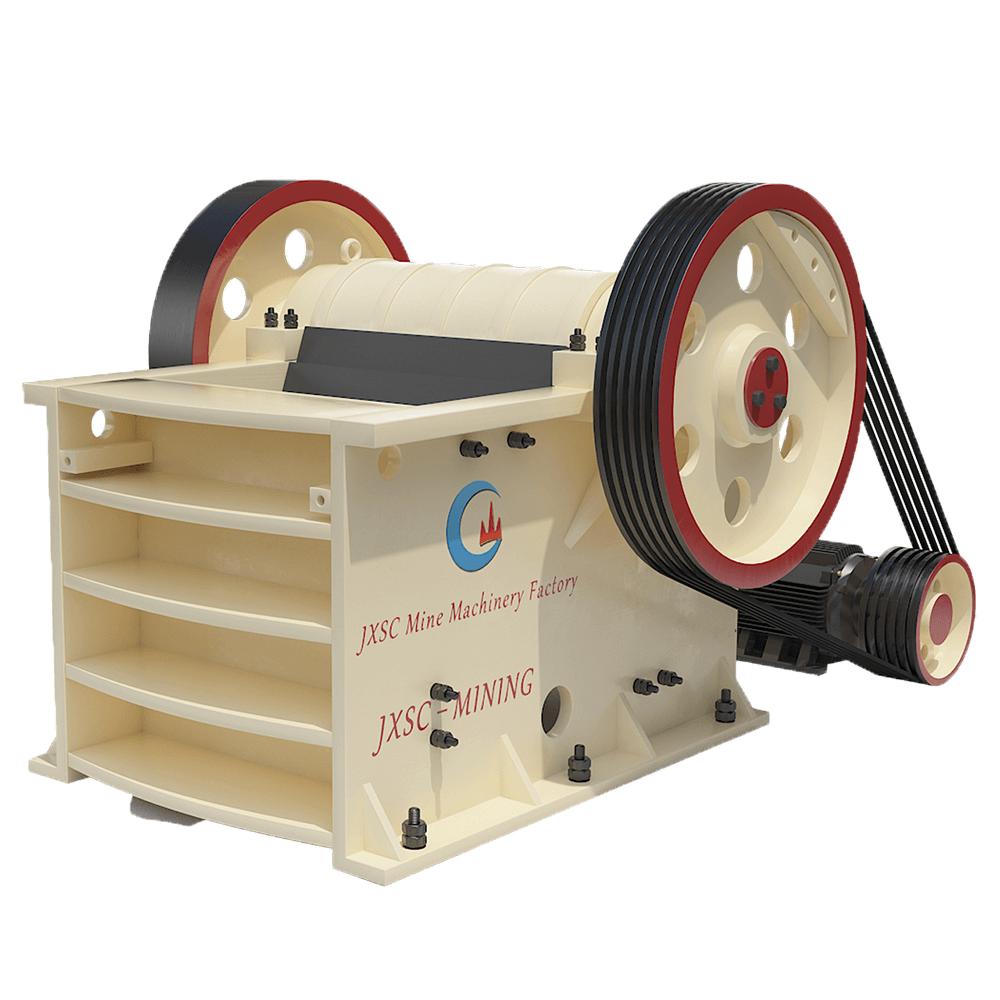

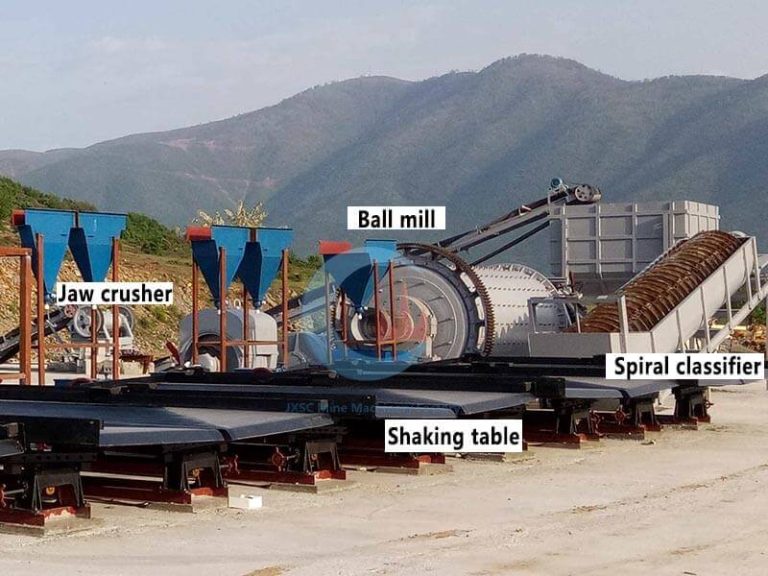

1. Crushing stage: jaw crusher, hammer crusher

The 0-150mm material enters the 200*300 jaw crusher through the trough feeder, the crushed material is transported to the hopper through the belt conveyor, and feed to the 600*800 hammer crusher by the electromagnetic vibrating feeder for secondary crushing.

2. Gravity separation: shaking tables

It is crushed into materials smaller than 3mm by the hammer crusher, transported to the 6s shaker table, and the tungsten ore concentrate and tailings are separated by gravity beneficiation.

3. Magnetic separation: three-disc dry magnetic separator

The tungsten ore concentrate is dried under the sun, and then enters the three-disc dry magnetic separator to separate the iron ore and improve the grade of the tungsten concentrate.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.