Gold Processing Plant

Engineered for maximum gold recovery with minimum environmental impact. Trusted by mines in over 60 countries since 1985.

Gold processing plant includes gravity separation and flotation process, CIP, CIL process, and heap leaching, etc. JXSC supports customized complete high configuration and best economical gold beneficiation solutions and equipment according to the specific properties of gold ore. Maximize the recovery or extraction of valuable minerals, and improve the purity of gold ore.

Application: It is suitable for processing and separating placer/ alluvial, hard rock gold ore, sulfide ore, gold-bearing polymetallic ores, telluride-bearing gold ore, gold-bearing tailings, etc.

Gold Beneficiation process

The gold beneficiation process is gravity separation, flotation, magnetic separation, cip, cil , heap leaching and other combined methods.

Key processes for three gold ore types

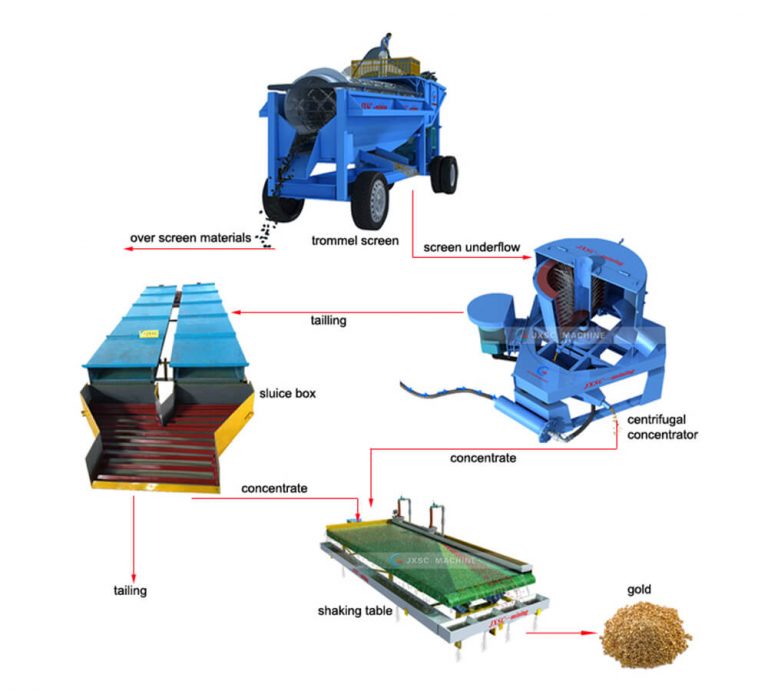

- Alluvial/Placer gold process: The gold concentrate of placer gold ore has a high content and mostly exists in the form of sand grains. Therefore, gravity separation is often used when sorting. After pretreatment, desliming and washing of ore, coarse gold ore particles can be directly obtained by gravity separation process.

- Rock gold process: The hard rock gold processing plant is very efficientwith a recovery rate of 95%, primarily by removing most of the individual crude gold ore through gravity separation process. Commonly used processes also flotation, CIL and CIP process.

- Associated gold ore process: depleted sulfide gold ore, polysulfide gold ore, gold-bearing polymetallic ore, telluride-bearing gold-gold ore, and gold-bearing copper ore. According to the nature of the ore, the application of multiple combined processes is often used to select the minerals separately.

Gold Ore Process

gold processing plant solutions

Gold Ore processing Plant

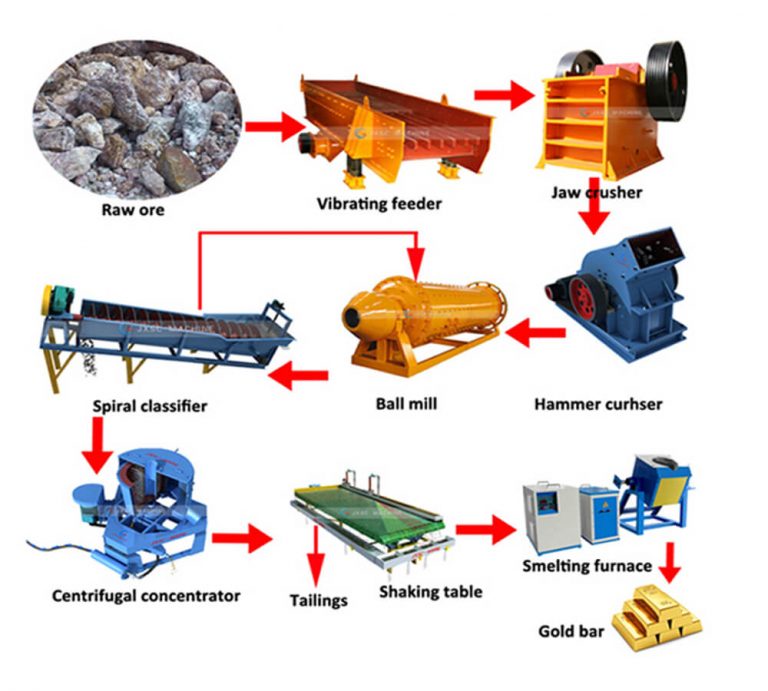

Gold ore processing plants are common including washing & screening, crushing & grinding, beneficiation, concentration, drying or smelting.

1. Washing & screening: It is mainly to remove the mud in the placer gold ore, or to make the particle size meet the requirements of the sorting operation.

2. Crushing & grinding: The content of gold in the ore is extremely low. To extract gold, gold ore processing equipment crushes and grinds the ore and adopts ore dressing methods to pre-enrich or separate gold from the ore.

3. Beneficiation stage: According to the characteristics of various types of ores, one or more comprehensive separation processes of gravity separation, flotation, cyanidation, carbon slurry and adsorption are adopted.

4. Tailings processing: Generally, the concentration + filtration + dehydration process is mostly used. If required, suitable reprocessing can also be customized according to the nature of the tailings.

5. Smelting: After obtaining high-purity gold, it can be cast into gold nuggets, coins or other shaped products by melting furnace according to needs.

gold processing plant for sale

JXSC has over 40 years of experience in all types of gold processing equipment, and our ability to combine craftsmanship and robust design makes us your one-stop solution for small-scale gold process plants. It supports customized gold processing plants and equipment, portable machine supplier, is not limited by the site and is easy to move.

small Modular gold processing plant

Mobile gold wash plant

Capacity: 1TPH to 300TPH

Trommel screen + sluice box

small gold/diamond wash plant

Capacity: 1-20 TPH

Gold trommel + Jig separator

One-stop gold washing plant

Capacity: 5 T/H to 250T/H

Trommel scrubber + Sluice box

gold mining gravity table

Capacity: 10-20 t/d, Up to 60t/d

Centrifugal concentrator + Shaker

Why Choose JXSC Gold Processing Plant

High Recovery Rate

Advanced gold beneficiation technology ensures up to 98% gold recovery from both alluvial and hard rock deposits.

Cost Effective

Machines 100% factory price, low operating costs with energy-efficient components components and minimal water requirements.

Custom Solutions

Tailored configurations available to match specific ore characteristics and needs. Modular design allows for rapid setup.

Global Support

Supply eco-friendly process, backed by 40+ years of experience and service networks in over 60 countries worldwide.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.