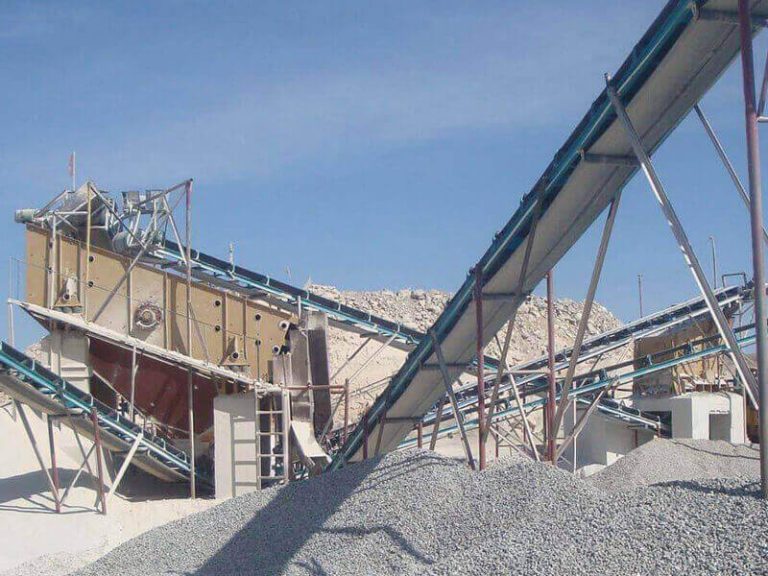

100TPH Alluvial Gold Porcessing Plant in Pakistan

We guarantee the high quality machine in the mineral processing industry, established in 39+ years of experience!

Project info.

minerals

alluvial gold, with sticky clay

capacity

100TPH in Pakistan

feed size

raw material 10mm, gold size in 0.1-1mm, contains 10-15% clay

Customer's request

wash away clay and separate the gold as much as possible

process flow

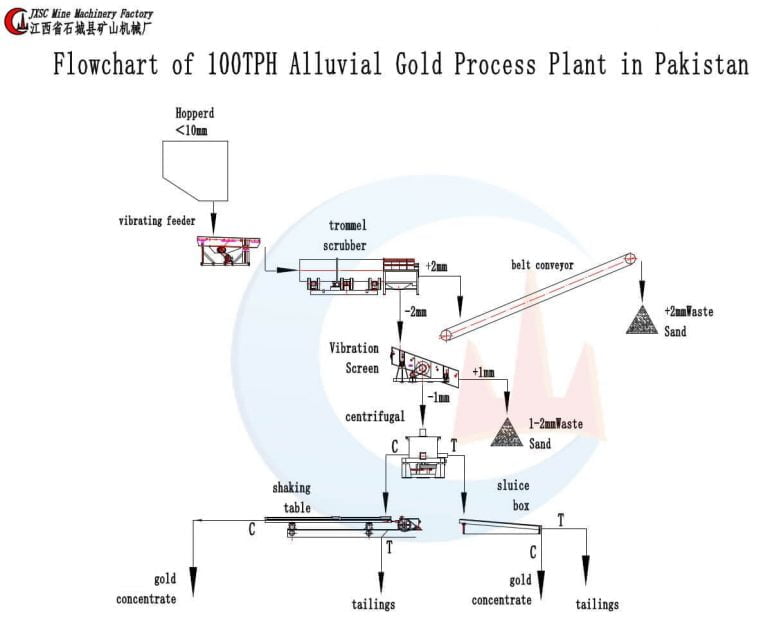

100TPH Alluvial Gold Porcessing Plant

1.Feeding: vibrating feeder

Loader or Excavator feed raw ore into the hopper; Vibrating feeder feed raw ores into trommel scrubber.

2.Washing & Screening: trommel scrubber, vibrating screen

Trommel scrubber is to wash off heavy clay from ore, and screen out different sized particles. Overscreen materials of trommel are transported to far place by belt conveyor, this is waste sands/stones. Under-screen materials with -2mm of trommel are sent to the vibrating screen and two kinds of materials are screened out at the same time. Minerals with +1mm are discharged and belong to waste sand. -1mm materials are sent to the centrifugal concentrator.

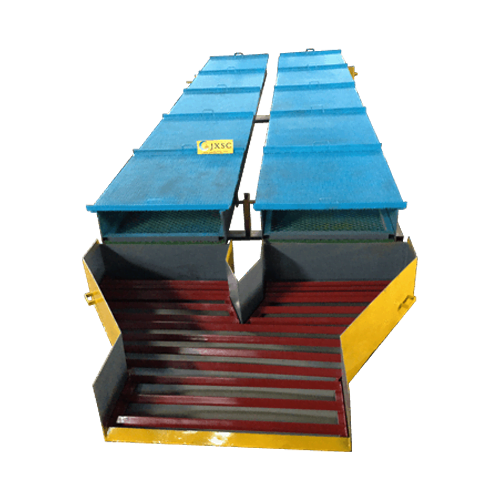

3.Gravity separation: gold centrifugal concentrator, sluice box

Tailings of centrifugal concentrator will be sent to sluice box for recovering more gold. Concentrates of centrifugal concentrator are sent to shaking table for final concentration gold in order to increase the purity of gold content.

Main Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, no investing)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.

featured products

All services in one place

Before sale

Be a good customer’s adviser and assistant, let the user’s every investment get rich returns.

(1) selection of equipment model.

(2) design and manufacture products according to customers’ special requirements.

(3) training technical personnel for customers.

Before sale

Respect customers; Give customers rest assured, a relaxed, a surprise; Committed to improving the overall value of customers.

(1) product acceptance.

(2) assist the client to draw up the construction plan.

After sale

(1) assign special after-sales service personnel to guide the installation and debugging of customers on-site.

(2) equipment installation and debugging.

(3) on-site training of operators.