Hydrocyclone

Capacity: 0.1-900 m³ /h

Application: Classification, concentration, dehydration, desliming, sand removal, washing, superfine classification of various minerals, separating and removing heavy mud in mineral processing plant.

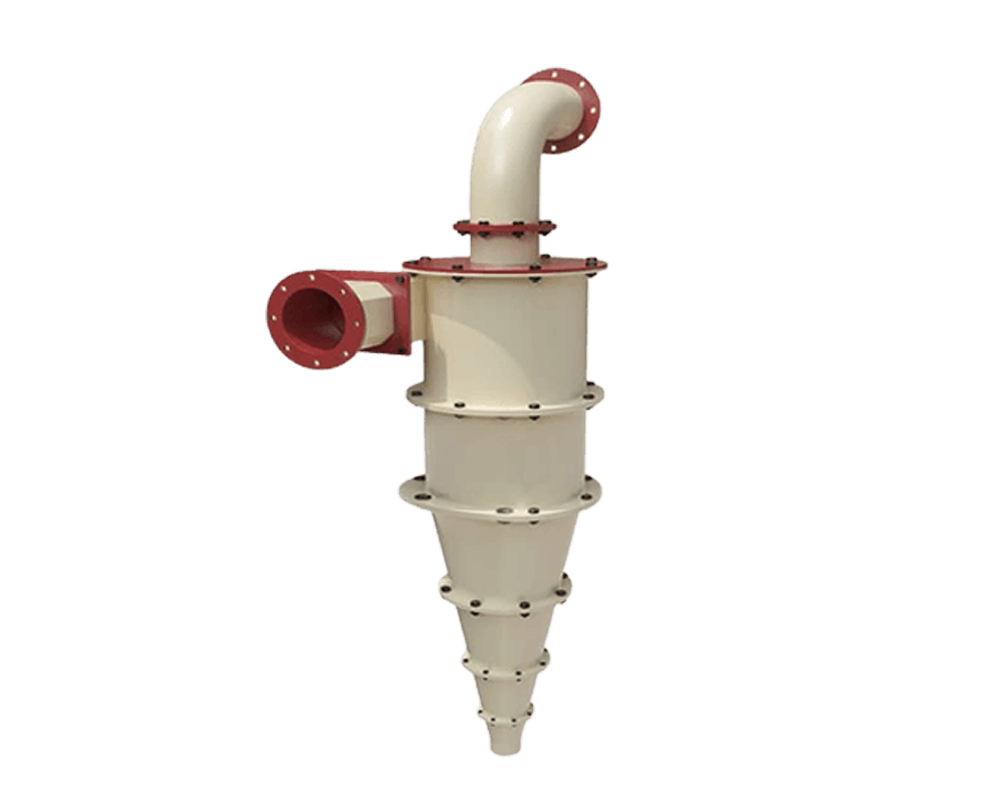

Products display

introduction of Hydrocyclone

The hydrocyclone is common mining classification equipment that uses centrifugal force to accelerate the sedimentation of ore particles. It is mostly used for grading operations in the second stage of closed-circuit grinding, and is sometimes used for mud dehydration to obtain very fine overflow products. We can also customize multiple hydrocyclones to form a group to improve classification efficiency.

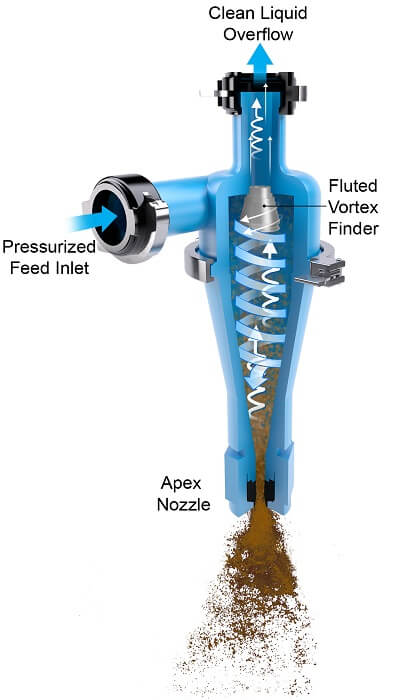

Working Principle Of Hydrocyclone

The structure of the hydrocyclone is relatively simple. Its upper end is a cylindrical part, and its lower part is a conical container.

The slurry is fed into the cyclone at a certain speed (generally 5 to 12 meters per second) along the tangential direction, and obtains a rotary motion, thus generating a large centrifugal force (usually tens of times or even hundreds of times greater than gravity) . Under the action of centrifugal force, the coarser particles are thrown toward the wall of the vessel and move downwards with a spiral track, which is discharged from the grit nozzle to become coarse-grained products; the finer particles and most of the water are in the spiral path, discharge from the flow tube.

why choose JXSC Hydrocyclone

features & Advantages of Hydrocyclone

1. It can adapt to liquids of different flow rates and particle sizes, effectively remove fine solid particles, and help remove suspended solids, sediment or other solid impurities;

2. With no moving parts, maintenance costs are relatively low;

3. Compact design, takes up relatively little space and is easy to operate;

4. Hydrocyclone performance can be optimized by adjusting the feed flow rate, feed concentration, and cyclone geometric parameters to meet the requirements of different applications.

models & specifications

Model | Diameter | Angle of Cone(°) | Diameter of overflow outlet (mm) | Diameter of Spigot (mm) | Max feeding size (mm) | Inlet pressure (mpa) | Capacity | Separation particle size (um) | 0verall Dimension | Unit weight | ||

(mm) | (m3/h) | Length | Width | Height | ||||||||

FX840 | 840 | 20 | 280~380 | 80~220 | 18 | 0.04~0.2 | 500~900 | 74~350 | 1700 | 1500 | 3700 | 1621 |

FX750 | 750 | 45 | 180~290 | 85~175 | 16 | 0.04~0.2 | 400~500 | 74~300 | 1210 | 910 | 2680 | 1400 |

FX710 | 710 | 45 | 175~270 | 80~165 | 16 | 0.03~0.2 | 350~450 | 74~250 | 1255 | 1185 | 1040 | 1250 |

FX660 | 660 | 20 | 165~250 | 80~155 | 16 | 0.03~0.2 | 250~350 | 74~220 | 1140 | 1000 | 2920 | 800 |

FX660 | 660 | 45 | 165~250 | 80~155 | 16 | 0.03~0.2 | 250~350 | 74~220 | 1140 | 1000 | 2000 | 995 |

FX610 | 610 | 20 | 155~230 | 75~140 | 13 | 0.03~0.2 | 200~300 | 74~220 | 875 | 950 | 2560 | 550 |

FX610 | 610 | 45 | 155~230 | 75~140 | 13 | 0.03~0.3 | 200~300 | 74~220 | 875 | 950 | 1810 | 600 |

FX500 | 500 | 20 | 125~185 | 55~115 | 10 | 0.03~0.3 | 140-220 | 74~220 | 850 | 700 | 2050 | 380 |

15 | 74~150 | 850 | 700 | 2380 | 540 | |||||||

45 | 74~150 | 850 | 825 | 1630 | 430 | |||||||

FX350 | 350 | 20 | 80~120 | 30~70 | 6 | 0.04~0.3 | 60~100 | 50~150 | 775 | 620 | 1765 | 208 |

15 | 50~120 | 775 | 620 | 1970 | 210 | |||||||

FX300 | 300 | 20 | 60~115 | 20~50 | 5 | 0.04~0.3 | 45~85 | 50~150 | 498 | 485 | 1415 | 105 |

15 | 40~100 | 498 | 485 | 1642 | 169 | |||||||

Fx250 | 250 | 20 | 60~100 | 16~45 | 3 | 0.06~0.35 | 40~60 | 40~100 | 410 | 380 | 1215 | 75 |

15 | 40~100 | 410 | 380 | 1405 | 73 | |||||||

10 | 30~100 | 410 | 380 | 1788 | 85 | |||||||

FX200 | 200 | 20 | 40~65 | 16~32 | 2 | 0.06~0.35 | 25~40 | 40~100 | 365 | 330 | 1030 | 45 |

15 | 30~100 | 410 | 330 | 1083 | 54 | |||||||

10 | 30~100 | 400 | 365 | 1490 | 60 | |||||||

F150 | 150 | 20 | 30~45 | 8~22 | 1.5 | 0.06~0.35 | 11~22 | 30~74 | 310 | 265 | 820 | 29 |

15 | 30~74 | 310 | 265 | 878 | 30 | |||||||

10 | 30~74 | 310 | 265 | 1160 | 35 | |||||||

FX125 | 125 | 17 | 25~40 | 8~18 | 1 | 0.06~0.35 | 8~15 | 20~100 | 260 | 218 | 620 | 10.2 |

8 | 20~74 | 260 | 218 | 870 | 33 | |||||||

FX100 | 100 | 20 | 20~40 | 8~18 | 1 | 0.06~0.35 | 5~15 | 20~100 | 260 | 210 | 525 | 8.6 |

15 | 20~100 | 268 | 215 | 720 | 13 | |||||||

8 | 20~100 | 365 | 150 | 1065 | 23 | |||||||

5 | 20~100 | 365 | 150 | 1505 | 30 | |||||||

FX75 | 75 | 15 | 15~22 | 6~12 | 0.6 | 0.1~0.4 | 2~5 | 20~74 | 240 | 230 | 420 | 2.2 |

5 | 5~40 | 240 | 230 | 778 | 6.5 | |||||||

FX50 | 50 | 15 | 11~16 | 3~8 | 0.3 | 0.1~0.4 | 1~2 | 10~74 | 160 | 137 | 400 | 1.5 |

5 | 160 | 137 | 680 | 5.5 | ||||||||

FX25 | 25 | 5 | 6~10 | 3~7 | 0.2 | 0.1~0.4 | 0.8~1.2 | 4~20 | 130 | 85 | 495 | 1.2 |

FX10 | 10 | 4 | 3~4 | 2~3 | 0.2 | 0.2~0.4 | 0.1~0.2 | 2~10 | 30 | 30 | 195 | 2 |

Structure of hydrocyclone

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.