Mineral Processing » Solutions » Coal washing process

Coal washing process

The hardness of coal itself is not high. We mainly provide equipment for coal mines crushing production lines.

The complete process includes washing coal of soil and rock, crushing and screening it into graded-sized chunks, dewatering, drying, stockpiling grades, and preparing it for transport to market.

Coal Processing methods

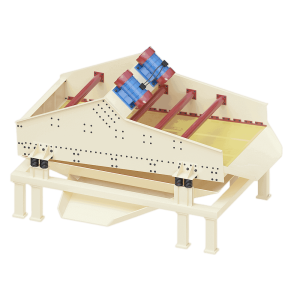

1. Crushing & Screening

The mixed materials with different particle sizes are divided into various particle poles by the screen surface with holes, and the coal lumps are sieved by dry or wet sieving. The selected coal pieces need to be pulverized to a certain particle size to pulverize large pieces of material into small particles.

2. washing

Coal washing process is an indispensable process of coal deep processing. The coal directly mined from the mine is called raw coal. Raw coal is mixed with many impurities in the mining process, and the coal quality is also different. Coal washing process is an industrial process to eliminate raw coal impurities or classify high-quality and low-quality coal.

3. separation

Using the different physical and chemical properties of coal and other substances, the impurities mixed in the raw coal are treated mechanically in the coal preparation plant, and the treated clean coal is divided into products of different qualities and specifications. Usually, the coal process is divided into jig gravity separation, heavy medium, and flotation separation.

4. Dewatering process

If it is thermal coal, the sorting has already met the requirements. At this time, the washed clean coal can be dehydrated into the coal storage bunker. Then the produced wastewater is concentrated and precipitated by thickener. The coal slime may enter the tail coal bunker and be stacked in the open air, and the clean water can be used for circulating water.

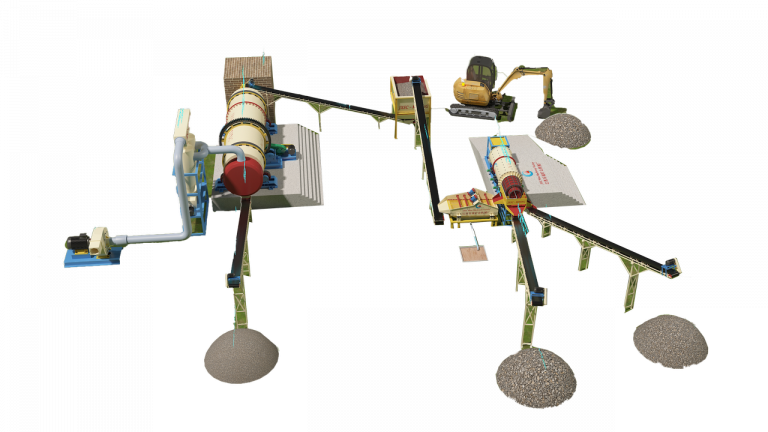

Coal Washing Process Plant

1. Coal Washing Plant

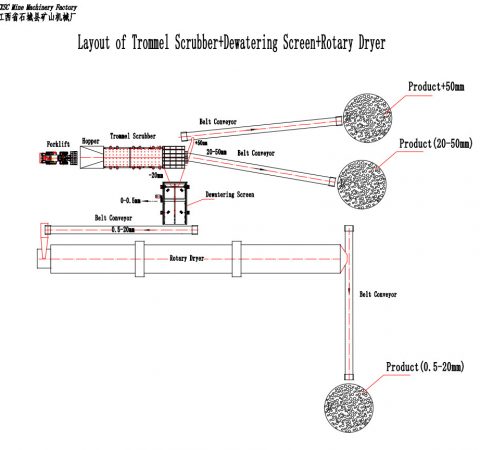

(1). The excavator or loader feeds raw materials to the hopper of trommel scrubber; here trommel scrubber with 2-layer screen at the end. After washing off the clay, screen three outputs: above 50mm,20-50mm, and below 20mm. Above 50mm and 20-50mm, outputs are transported to another place by belt conveyors.

(2). Below 20mm go to the dewatering screen by gravity flow. Here, the dewatering screen is lower than the trommel scrubber, so 0-20mm slurry can flow to the screen by height difference.

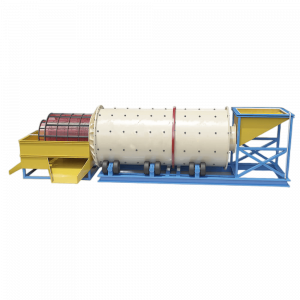

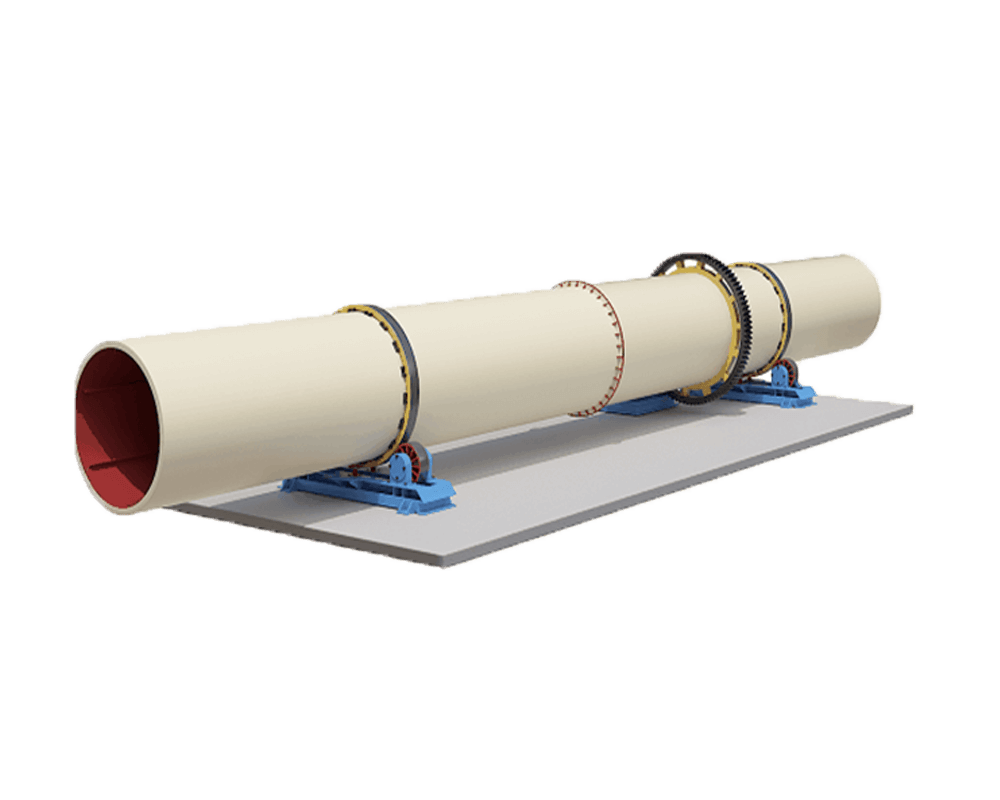

(3). Over-screen materials of the dewatering screen are sent to a rotary dryer system for drying coal by feeding conveyor.

4. The finished product after drying is transported by discharging conveyor.

Highlights of this coal wash plant

- Trommel scrubber screening and separating coal ores get 3 different sizes of output;

- Using a rotary dryer to obtain dry coal products.

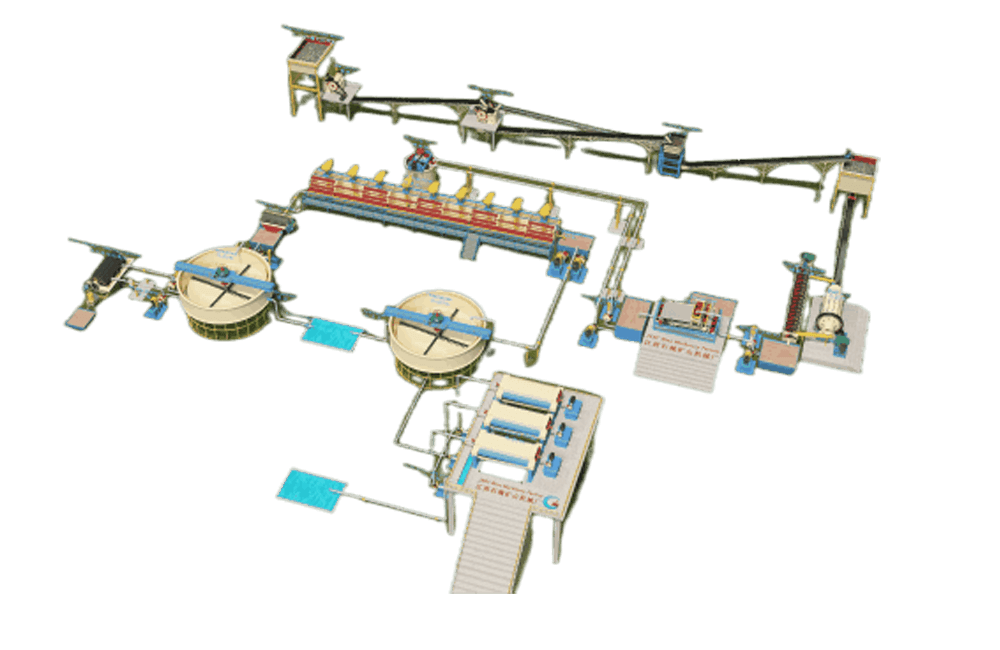

2. Coal crushing Plant

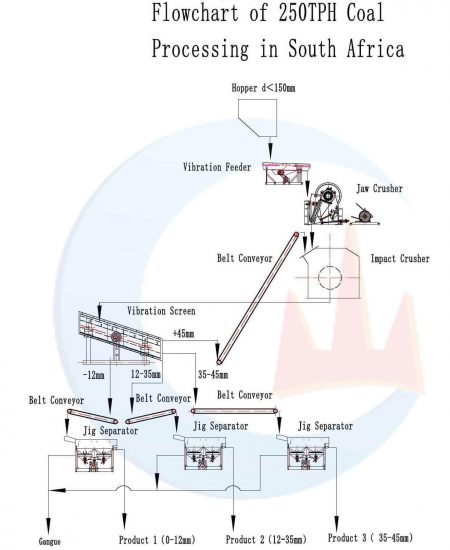

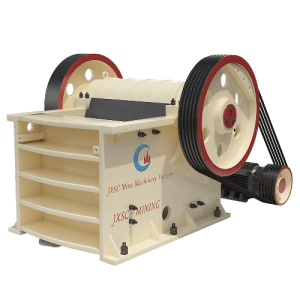

(1). Crushing: The large pieces of coal are sent to the jaw crusher by the vibrating feeder for rough crushing, and the conveyor transports the coarsely crushed materials to the impact crusher. The impact crusher is suitable for medium or fine crushing to further dissociate clean coal.

(2). Screening: The vibrating screen screens out three kinds of materials with different particle sizes, which are transported to three jig separators by belt conveyors for separation.

(3). Separation: less than 12mm, 12-35mm, 35-45mm, respectively enter the jig for separating.

① The process flow is single, the equipment operation and maintenance are simple, and the screening capacity is large;

② There is no coal type limitation on the coal preparation accuracy. Whether it is difficult coal preparation, easy coal preparation, or medium optional coal, the coal preparation accuracy meets the requirements.

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.