Beach Sand Beneficiation

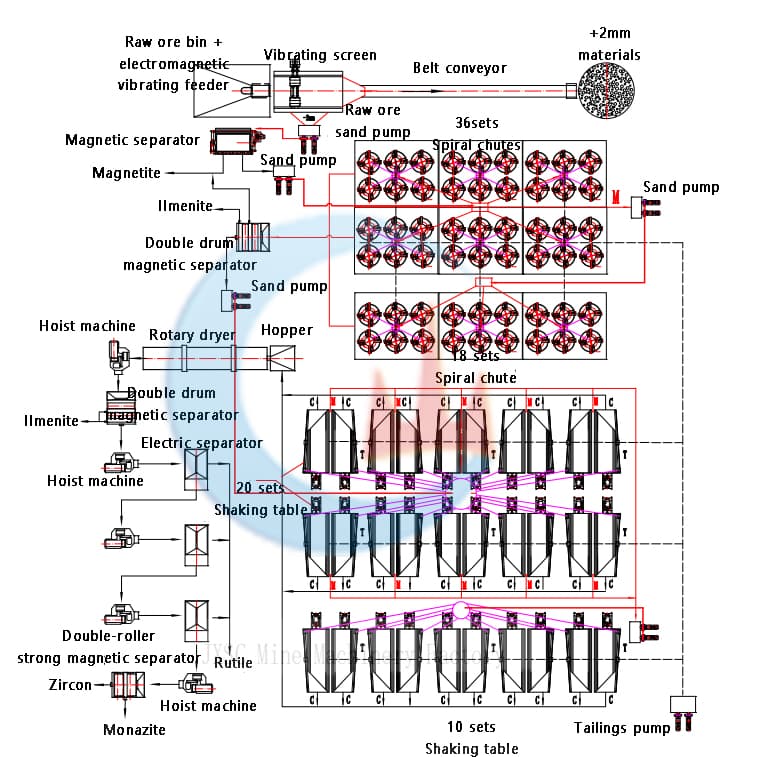

Complete beach sand beneficiation plant flow mainly includes crushing, gravity separation, magnetic separation, drying and electric separation.

The whole beach sand process is widely used in rutile, monazite, garnet, ilmenite and zircon sand separation plants. JXSC supports customized process flow and equipment to maximize useful mineral recovery.

Beach sand beneficiation Process

Beach sand (seashore placer) is a secondary enrichment deposit formed by the accumulation of heavy mineral debris in the seashore area due to the action of rivers, waves, tides and ocean currents. There are many useful minerals in beach sand and the composition is complex, mainly including rutile, ilmenite, magnetite, cobalt, monazite, quartz sand, zricon, and other heavy mineral sand processing. Various beneficiation combined processes( gravity, magnetic and electric separation) are required to separate the target minerals.

- Firstly, adopt gravity separation and discard tailings to obtain rough concentrates containing ilmenite, magnetite, rutile, monazite, quartzite, etc.; then concentrate on the rough concentrates.

- Qualified titanium concentrate, chromite and monazite are separated from it by electric separation.

- Specific differences in magnetic or electrical properties exist among the various seashore placer rough concentrate components obtained through gravity separation.Therefore, magnetic separation, electric separation and other beneficiation processes are generally used to form a combined method for separating and enriching each component.

heavy mineral sand beneficiation process

Generally, magnetic separation, electric separation, and other mineral separation processes form a combined process flow to separate and enrich each group of valuable heavy minerals. Contact us to get the latest quote for beach sand separation equipment!

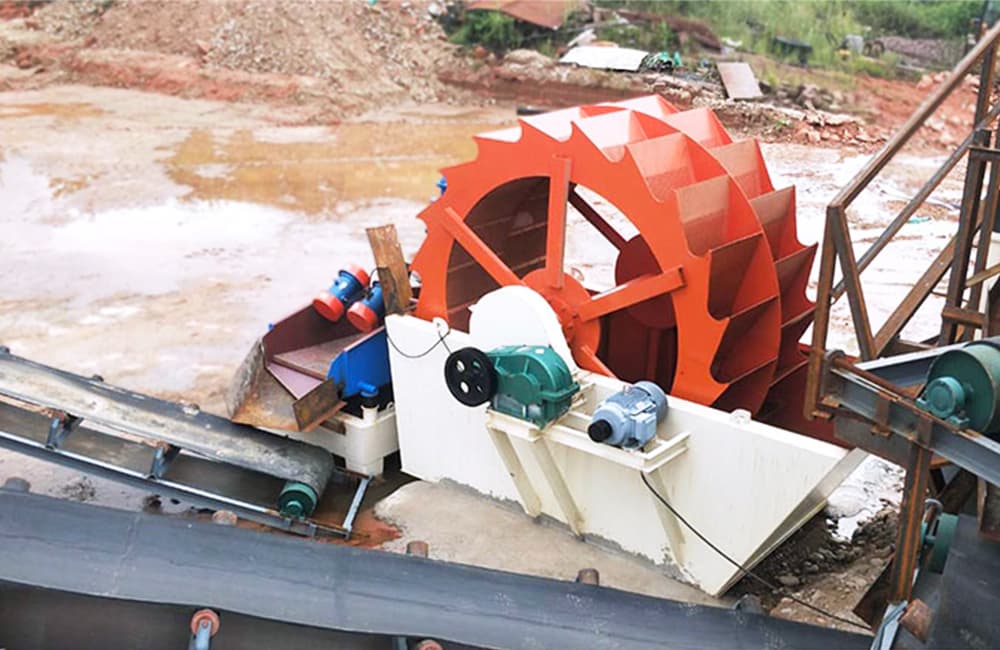

Beach sand processing Plant

Heavy mineral sand processing plant

This is a 100 t/h beach sand processing plant, main equipment and flow details as follows:

Raw ore information as below:

1-Capacity 100tph

2-Above 2mm impurities are removed

3-Need separate rutile, monazite, zircon, ilmenite, magnetite from the beach sand

Beach Sand Processing Plant Flow

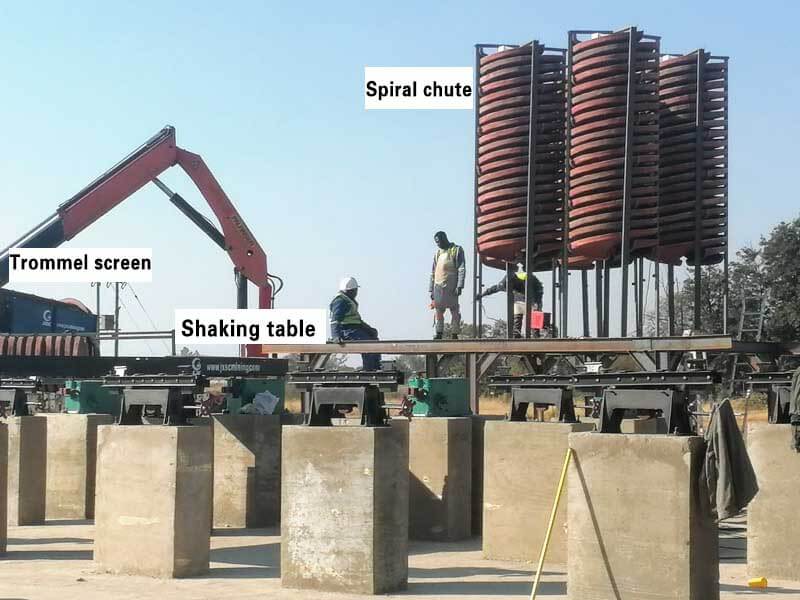

1. Feeding & Screening steps: The excavator or loader feeds the raw ore into the mine bin and then feeds the vibrating screen through the electromagnetic vibrating feeder. The vibrating screen adopts a 2mm sieve mesh layer to remove impurities above 2mm.

2. Gravity separation steps:

- The material below 2mm enters the magnetic separator from the slurry pump to separate the magnetite. The output of the magnetic separator is pumped from the slurry to the spiral chute. Light minerals are removed by gravity separation.

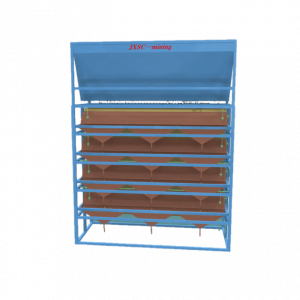

- The spiral chute gravity separation equipment has two stages: the middle ore of the first stage spiral chute equipment enters the second stage spiral chute for reprocessing. All concentrate from the two-stage spiral chute is sent to the first double-drum magnetic separator to separate the ilmenite. The output is pumped to the shaking table through the slurry pump, and the principle of gravity removes the light minerals.

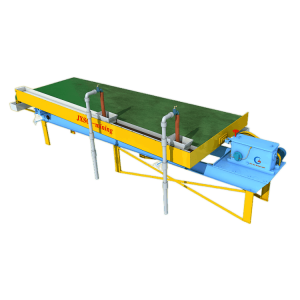

- The eight sets of shaking tables have two stages: the middle ore of the first stage shaking table is sent to the second stage shaking table for further processing through the slurry pump.

3. Magnetic separation steps: All concentrate from the shaker is sent to the rotary dryer to dry the material. The dried material enters the second double-drum magnetic separator through the elevator to separate the ilmenite.

4. Electrostatic separation steps: To separate rutile, other minerals in the second double-drum magnetic separator enter the first electrostatic separator through the elevator. Then enter the second electrostatic separator through the elevator to separate the rutile. The rutile is separated into the third electrostatic separator through the hoist. Then, other minerals enter the double-roller strong magnetic separator through the elevator, separating zircon and monazite.

The selection of specific beach sand beneficiation processes and equipment mainly depends on the type of ore. Contact us to customize the best mineral processing solutions!

Related Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.